Silver wire fixing support with prestress and forming method

A fixed bracket and prestressing technology, which is applied to explosives, greenhouse gas reduction, climate sustainability, etc., can solve the problems of not being able to fully utilize the charging space, not meeting the high requirements of missiles, and low loading ratio, so as to improve the charging rate. The effect of improving the design reliability and high filling ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the above technical solutions, the technical solutions of the present application will be described in detail below through the accompanying drawings and specific embodiments. It is not a limitation on the technical solutions of the present application, and the embodiments of the present application and the technical features in the embodiments may be combined with each other under the condition of no conflict.

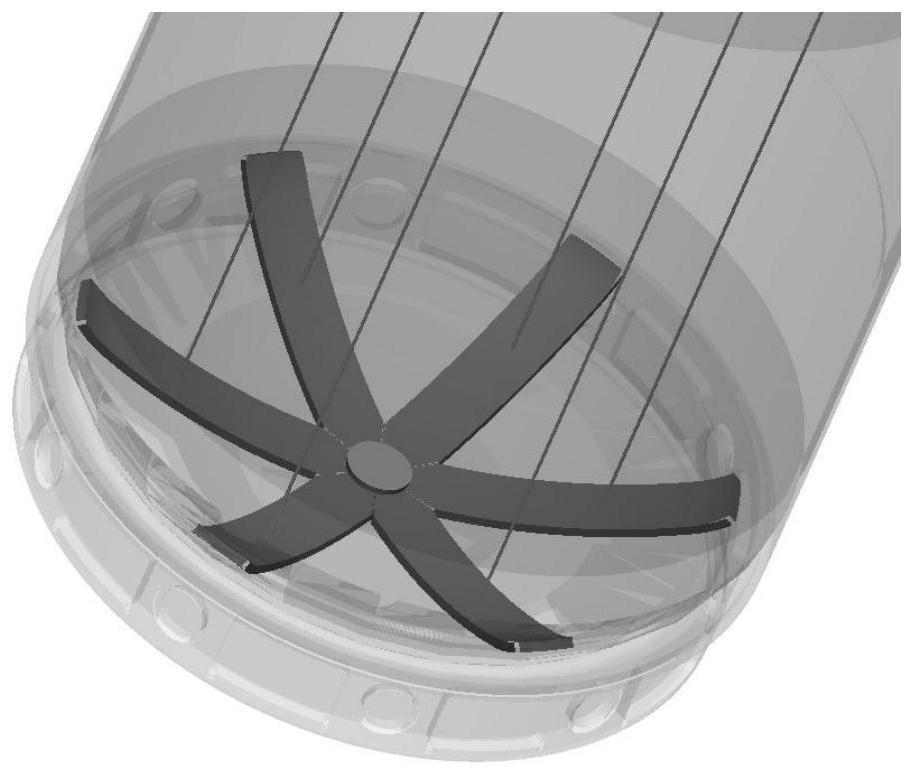

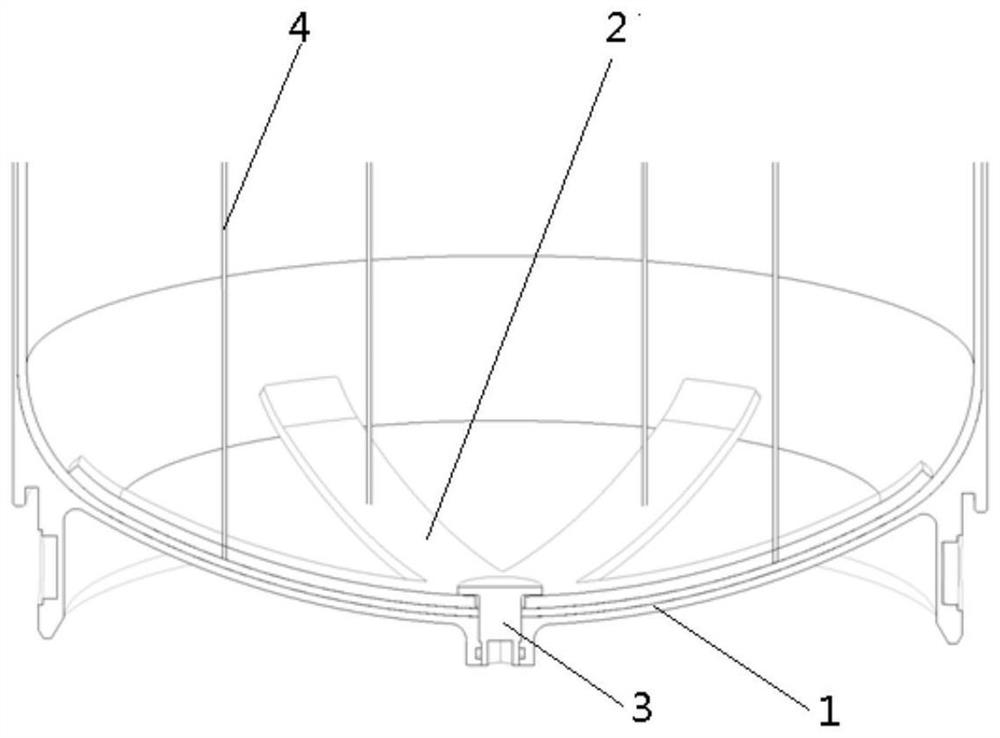

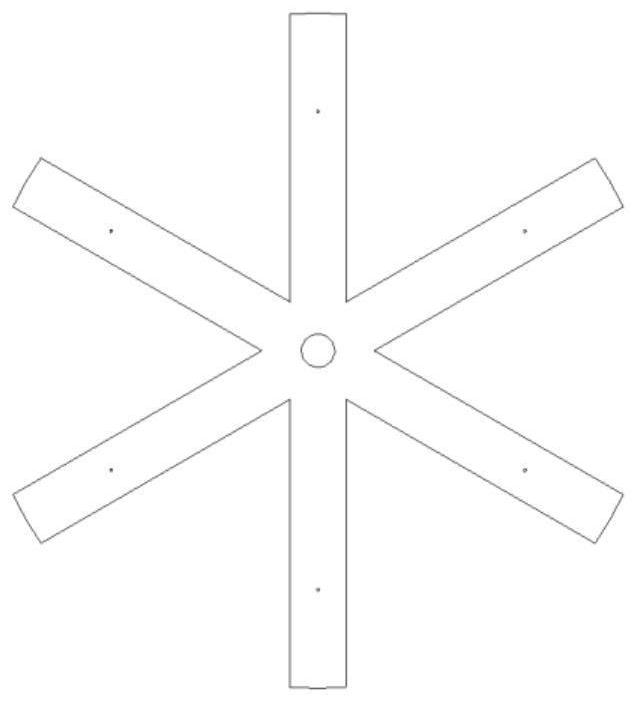

[0033] The following describes in further detail a silver wire fixing bracket and a forming method for casting and forming a silver wire end fuel column provided by the embodiment of the present application in conjunction with the accompanying drawings. The specific implementation methods may include (such as Figures 1 to 4 shown):

[0034] In the scheme provided by the embodiment of the present invention, figure 1 It is an integrated schematic diagram of the present invention containing silver wires, with prestressed brackets, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap