Weaving method and weaving equipment for perspiration single-sided exposure-proof knitted fabric

A light-needle, single-sided technology, used in knitting, weft-knitting circular knitting machines with separate action needles, and weft-knitting knitting directions, which can solve the problem of the decreased shielding effect of knitted fabrics, affecting the feeling of wearing light and thin, and reducing the air permeability of clothing, etc. The problem is to achieve the effect of simple and practical fabric weaving method, light and breathable wearing comfort, and reducing the penetration of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

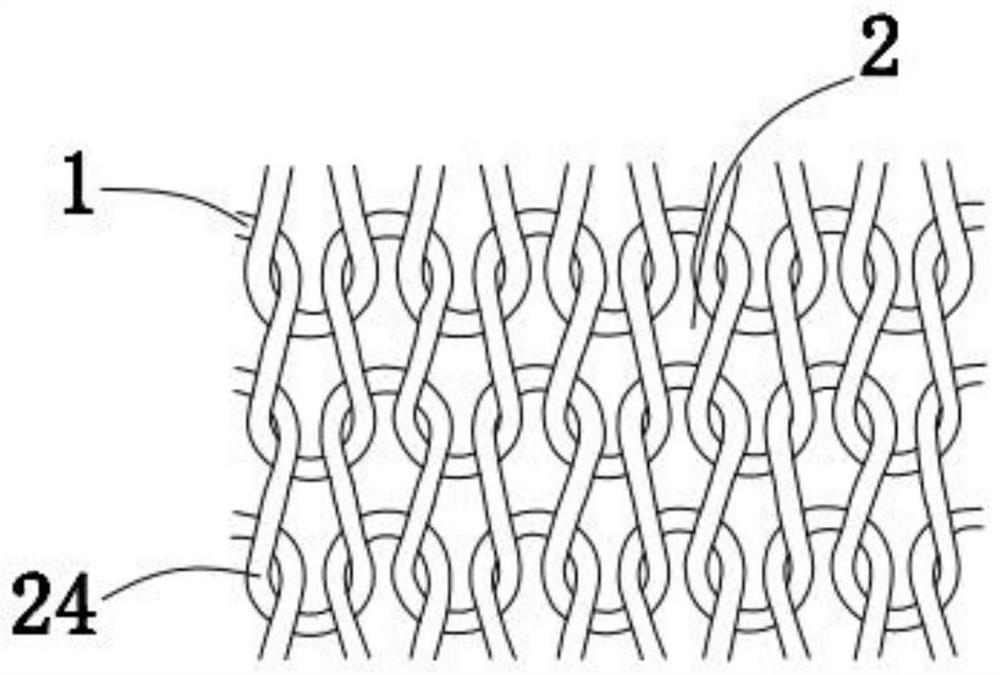

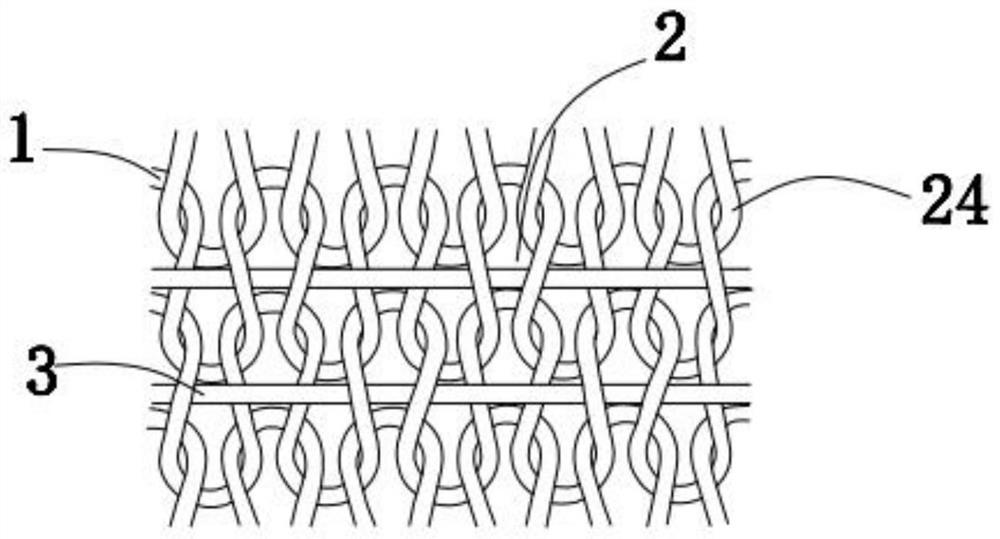

[0033] as Figure 2 、 Figure 4-Figure 10As shown, a perspiration-wicking single-sided anti-light knitting method of weaving, comprising the following steps:

[0034] S1: The hydrophilic yarn is selected as the second yarn 3, the hydrophobic yarn is used as the first yarn 1, and one end of the second yarn 3 and the first yarn 1 is bypassed by the yarn feeder and then passed through the yarn nozzle and wound and fixed on the starting end, and the yarn transmission height of the second yarn 3 is lower than the yarn transmission height of the first yarn 1;

[0035] S2: install and adjust the weaving equipment, the same number of weaving needles in the number of internal knitting needles 5 and external knitting needles 6 have multiple, and together with the syringe barrel 4 synchronous circle rotation, and then by the needle triangle 11 control needle, settlement plate 7 by the horizontal triangle 18 control needle after the needle is located between the two needles;

[0036] S3: The fi...

Embodiment 2

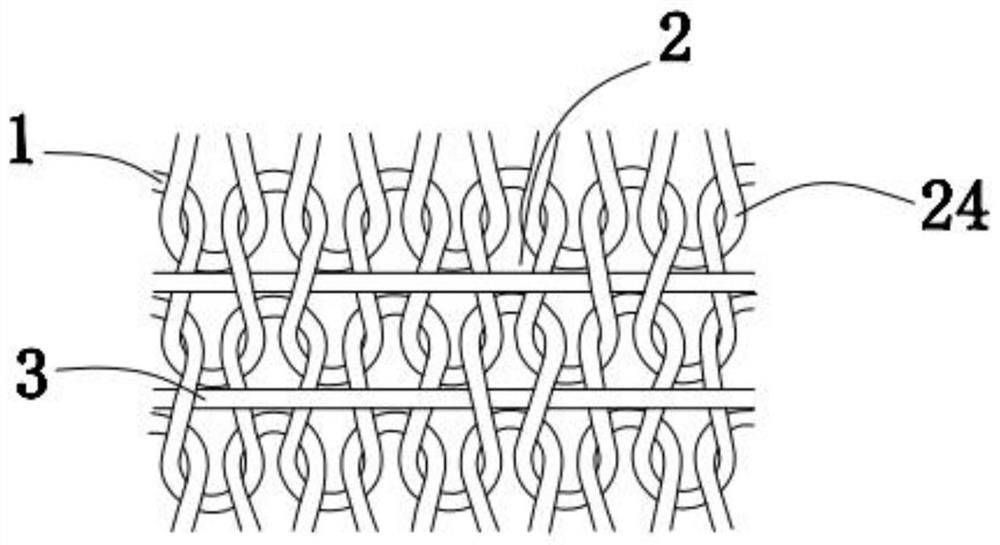

[0043] as Figure 3 As shown, the difference between the present embodiment and Example 1 is that the inner needle 5 is woven into a coil 24, the outer needle 6 becomes a coil 24 and the arrangement of the second yarn 3 is different, the number of coils 24 woven in the inner needle 5 in the present embodiment is twice the number of the outer knitting needle 6 woven coil 24, so that the second yarn 3 is exposed on the outside of the single-sided knitted fabric Is a larger area, the heat dissipation and sweating effect is better, and the first yarn 1 is a polysane fiber, polyamide fiber or polyamide fiber of the special-shaped section, and also passes through polysiloxane , surfactants, adsorbents and hydrophobic agents made of water treatment, and the second yarn 3 is a honeycomb modified polyester fiber as the core yarn, outsourced recycled fiber or cashmere fiber core yarn, so that the single-sided knitted fabric of the woven moisture and sweat-repellent effect is more significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com