Carbonized silk fabric/transition metal oxide composite material for flexible lithium ion battery negative electrode and preparation method thereof

A lithium-ion battery, transition metal technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of poor conductivity, slow diffusion of lithium ions, unstable structure, etc., and achieve simple preparation and good electrochemical performance. Effects of performance and mechanical flexibility, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a carbonized silk fabric / transition metal oxide composite material for a negative electrode of a flexible lithium-ion battery, the specific steps of the method are as follows:

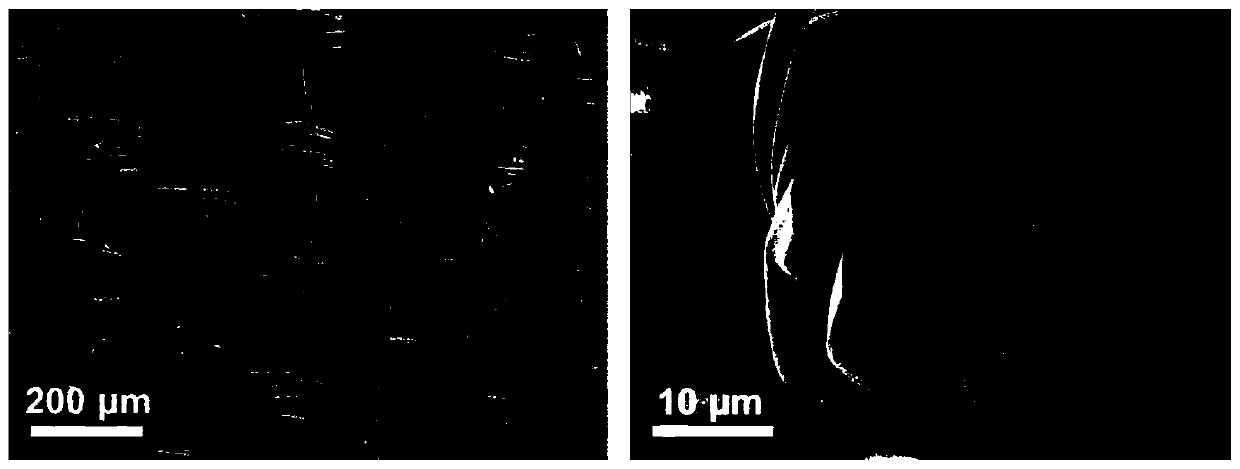

[0039](1) Preparation of carbonized silk fabric: Cut a piece of 3cm×4cm electric spinning silk fabric, place it in a tube furnace, and carbonize it in an argon atmosphere at 600°C for 3h, with a heating rate of 2°C / min and an argon flow rate of 40sccm, promptly obtains required carbonized silk fabric. The topography of carbonized silk fabric is shown in figure 1 .

[0040] (2) Carbonized silk fabric pretreatment: put the carbonized silk fabric obtained in (1) in 6M HCl solution, acid treatment at 100°C for 2 hours, after natural cooling, take out the carbonized silk fabric, wash with deionized water and absolute ethanol Washing was repeated 3 times in medium temperature and dried at 80°C for 12 hours to obtain pretreated carbonized silk fabric.

[0041] (3) Preparation ...

Embodiment 2

[0044] A method for preparing a carbonized silk fabric / transition metal oxide composite material for a negative electrode of a flexible lithium-ion battery, the specific steps of the method are as follows:

[0045] (1) Preparation of carbonized silk fabric: cut a 3cm×4cm crepe de chine silk fabric, place it in a tube furnace, and carbonize it in a neon gas atmosphere at 700°C for 4 hours, with a heating rate of 5°C / min and a neon gas flow rate of 40sccm, promptly obtains required carbonized silk fabric.

[0046] (2) Carbonized silk fabric pretreatment: put the carbonized silk fabric obtained in (1) in 4M HCl solution, acid treatment at 120°C for 4 hours, after natural cooling, take out the carbonized silk fabric, wash with deionized water and absolute ethanol Washing was repeated 3 times in medium temperature and dried at 80°C for 12 hours to obtain pretreated carbonized silk fabric.

[0047] (3) Preparation of carbonized silk fabric / transition metal oxide precursor: First, a...

Embodiment 3

[0050] A method for preparing a carbonized silk fabric / transition metal oxide composite material for a negative electrode of a flexible lithium-ion battery, the specific steps of the method are as follows:

[0051] (1) Preparation of carbonized silk fabric: Cut a piece of georgette silk fabric of 3cm×4cm, place it in a tube furnace, and carbonize it in a nitrogen atmosphere at 800°C for 4h, with a heating rate of 6°C / min and a nitrogen flow rate of 80sccm, namely Obtain the desired carbonized silk fabric.

[0052] (2) Carbonized silk fabric pretreatment: place the carbonized silk fabric obtained in (1) in 5M HNO 3 In the solution, acid treatment was carried out at 110°C for 2 hours. After natural cooling, the carbonized silk fabric was taken out, washed three times with deionized water and absolute ethanol, and dried at 80°C for 12 hours to obtain a pretreated carbonized silk fabric.

[0053] (3) Preparation of carbonized silk fabric / transition metal oxide precursor: First, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com