A combined processing method for high-strength and high-toughness h62 brass

A high-strength, high-toughness, combined processing technology, applied in the field of non-ferrous alloy processing, achieves good industrial application prospects, simple process operation and equipment requirements, and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

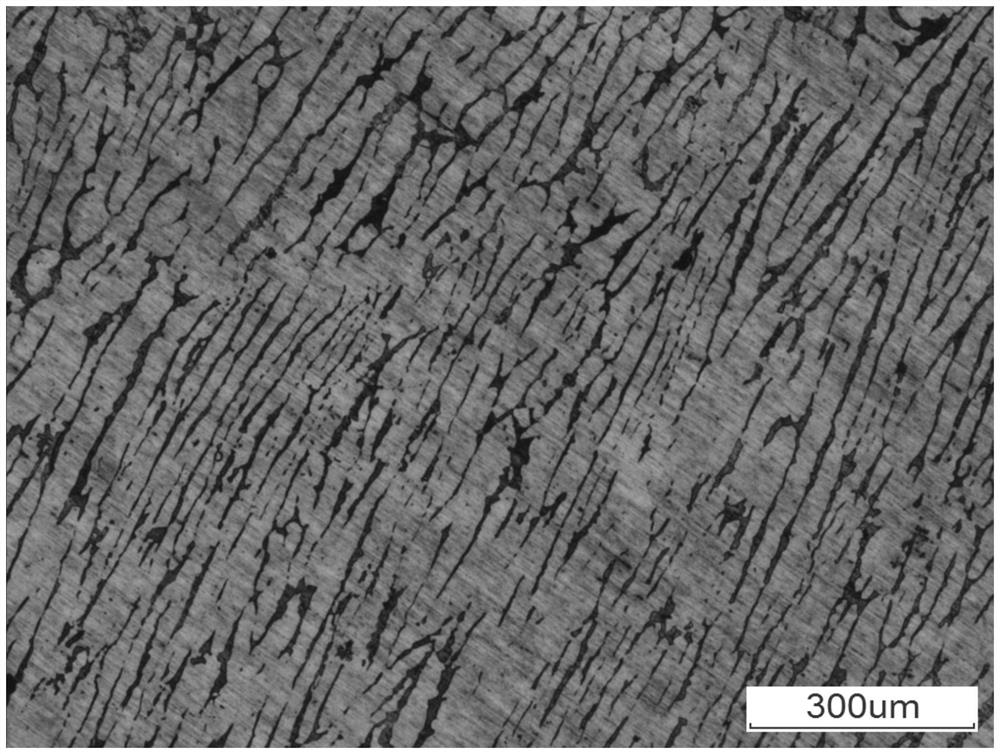

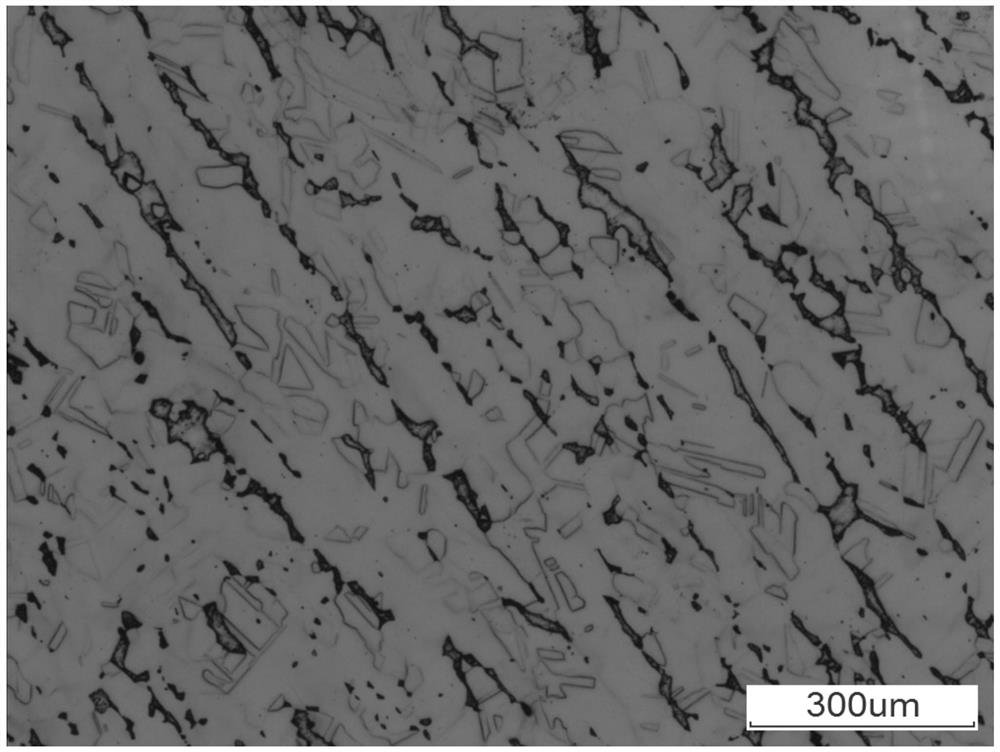

[0031] The purchased commercial H62 brass alloy was processed into a columnar test piece of 19.5mm×19.5mm×40mm by wire cutting. Composition, in which the α phase is a solid solution with Cu as the matrix and Zn as the solute atoms, and the β phase is a solid solution with CuZn electronic compounds as the base, and the crystal grains grow into strips, such as figure 1 shown. Then heat it at 560°C for 10 hours, then air-cool or water-cool for homogenization treatment, the H62 brass alloy β phase content obtained by homogenization treatment decreases, the grain size increases, and the grain shape presents a transition from elongated to equiaxed. state, such as figure 2 shown.

[0032] The test piece is pretreated according to the routine to obtain a clean surface, and the solid lubricant is evenly coated on the surface of the test piece and the mold surface, and then placed in a mold preheated to 350 ° C for 7 to 10 minutes, and then pressure is applied for 8 consecutive passe...

Embodiment 2

[0036] The purchased commercial H62 brass alloy was processed into a columnar specimen of 19.5mm×19.5mm×40mm by wire cutting, and then it was kept at 560°C for 10h and then air-cooled or water-cooled for homogenization.

[0037] The test piece is pretreated according to the routine to obtain a clean surface, and the solid lubricant is evenly coated on the surface of the test piece and the mold surface, and then placed in a mold preheated to 350 ° C for 7 to 10 minutes, and then pressure is applied for 8 consecutive passes of ECAP Extrusion, the sample is rotated 180° between adjacent extrusion passes to improve the uniformity of the extrusion structure, and after annealing at 300°C for 45 minutes, the content of β phase increases and the uniformity of grains improves.

[0038] The tensile strength of the purchased commercial H62 brass alloy is less than 400MPa, but at a temperature of 350°C, after 8 passes of ECAP extrusion, the tensile strength reaches 530MPa, and the overall el...

Embodiment 3

[0040] The purchased commercial H62 brass alloy was processed into a columnar specimen of 19.5mm×19.5mm×40mm by wire cutting, and then it was kept at 560°C for 10h and then air-cooled or water-cooled for homogenization.

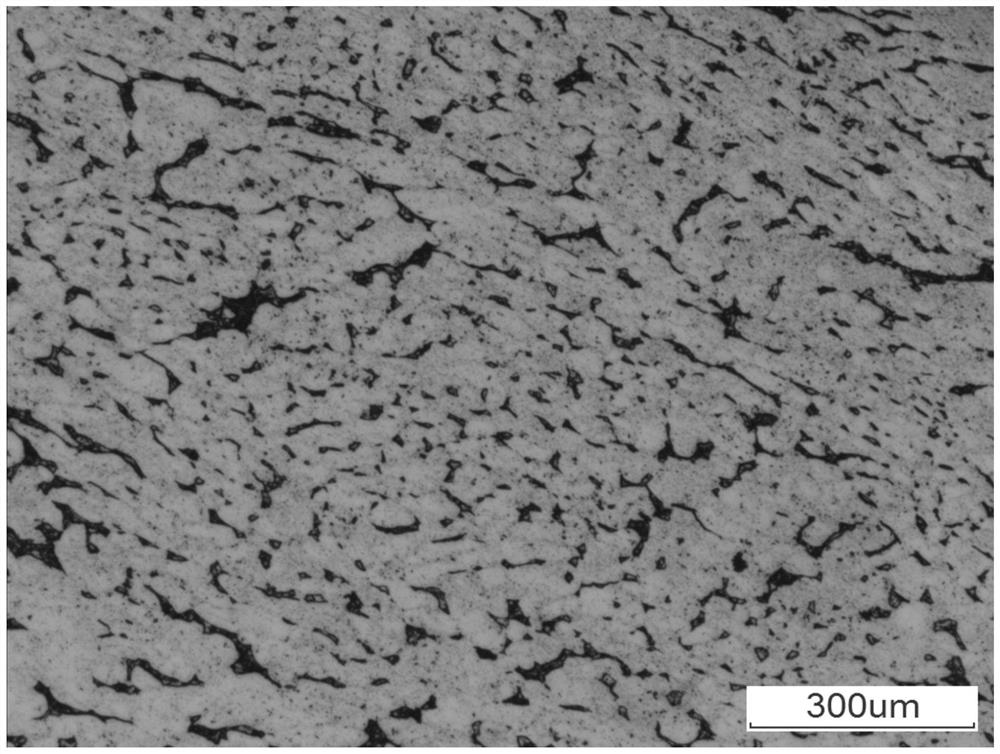

[0041] The test piece is pretreated according to the routine to obtain a clean surface, and the solid lubricant is evenly coated on the surface of the test piece and the mold surface, and then placed in a mold preheated to 350 ° C for 7 to 10 minutes, and then pressure is applied for 8 consecutive passes of ECAP For extrusion, the sample is rotated 180° between adjacent extrusion passes to improve the uniformity of the extruded tissue. After annealing at 300°C for 60 minutes, the content of β phase increases and the uniformity of grains increases, as shown in Figure 5 shown.

[0042] The tensile strength of the purchased commercial H62 brass alloy is less than 400MPa, but at a temperature of 350°C, after 8 passes of ECAP extrusion, the tensile strength reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com