Rapid assembly and disassembly construction method for horizontal cantilever net of high-altitude cantilever outer frame

A construction method and horizontal technology, which is applied in the field of rapid assembly and disassembly of high-altitude cantilevered outer frames and horizontal hoisting nets, can solve the problems of high-efficiency construction of unfavorable projects, unsatisfactory facade effects, and long construction process, so as to prevent the risk of falling from high altitudes. , to meet the safety construction requirements, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

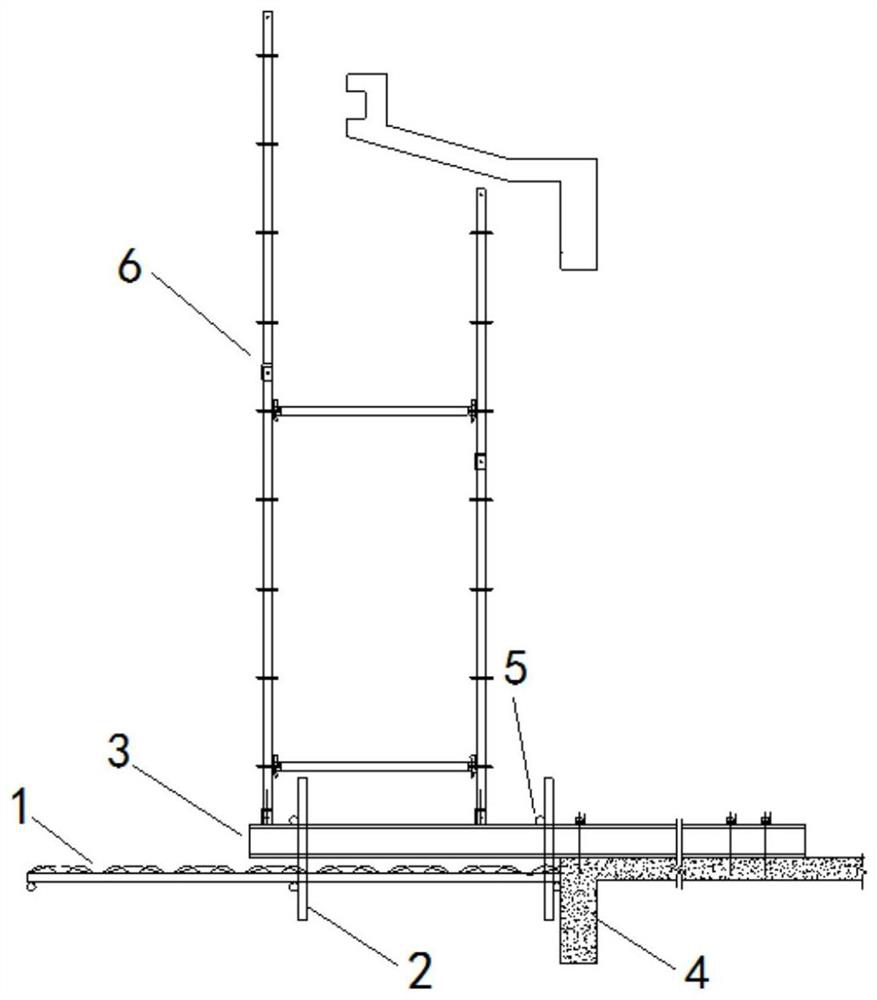

[0022] A construction method for rapid assembly and disassembly of a horizontal pick net of a high-altitude cantilevered outer frame, refer to Figure 1-4 , including the following steps:

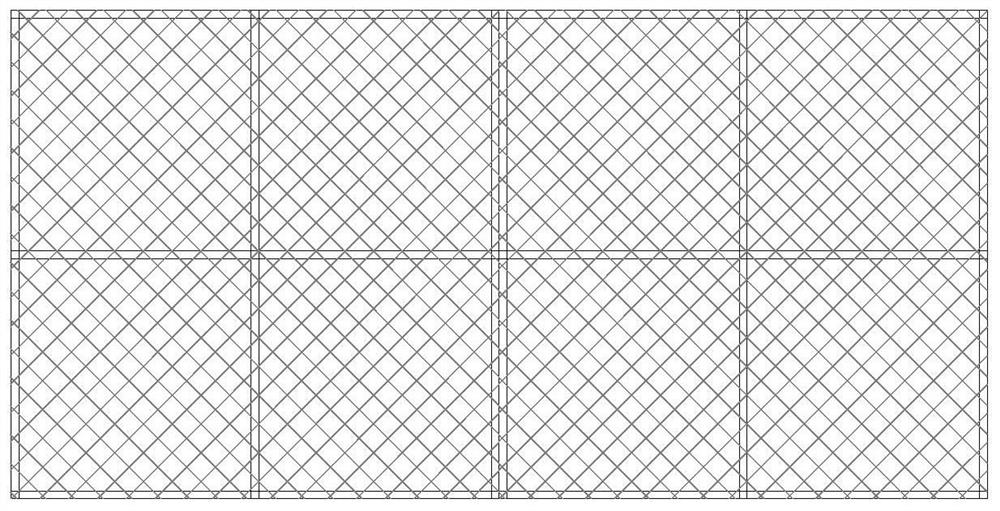

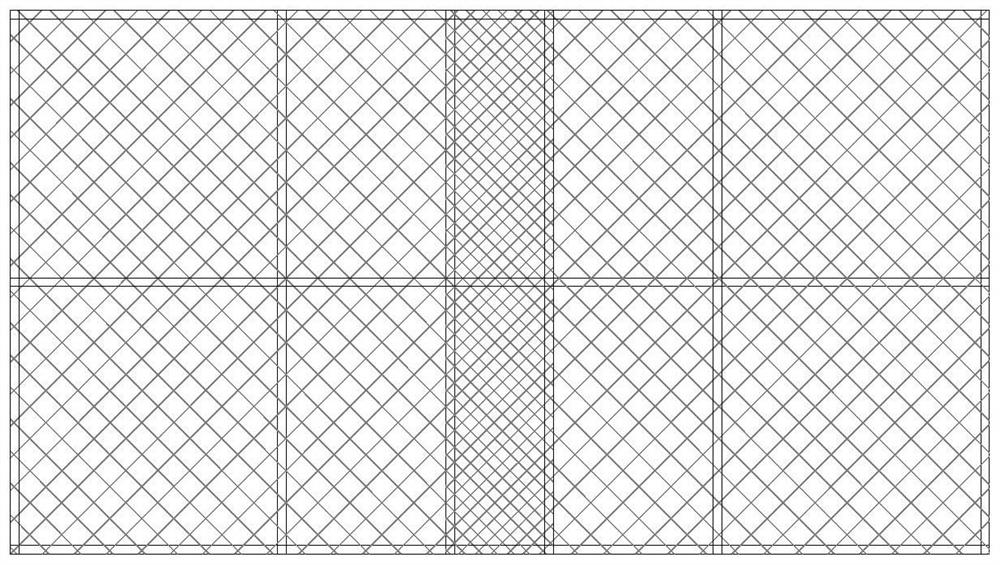

[0023] S1. Horizontal pick net assembly: Assemble horizontal pick net 1 on the ground. Ordinary steel pipes of φ48mm can be used. The main frame is erected vertically and then horizontally. The length varies from 3 to 6m, depending on the vertical length of the roof structure. The width is the length of the outside pick. It can be 3m, and the vertical and horizontal spacing can be 1.5m. It can be assembled into a "field"-shaped horizontal structure, and then hang safety nets and white nets. 30mm flat net, you can first lay a flat net pocket bottom on the main frame, and then lay a dense mesh net, and use 22# wire to bind and fix, and use 0.8m poles on both sides of the horizontal pick net 1 to erect several vertical connecting rod 2;

[0024] S2. Hoisting of horizontal pick nets: The roof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com