Detection device for tensile strength of tool bit and use method of detection device

A tensile strength, testing device technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test the strength of materials, etc., can solve the problem of inconvenient detection, no protective mechanism, and no way to actually simulate the tensile strength of the cutter head Strength and other issues, to prevent splashing, easy to use, and increase the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

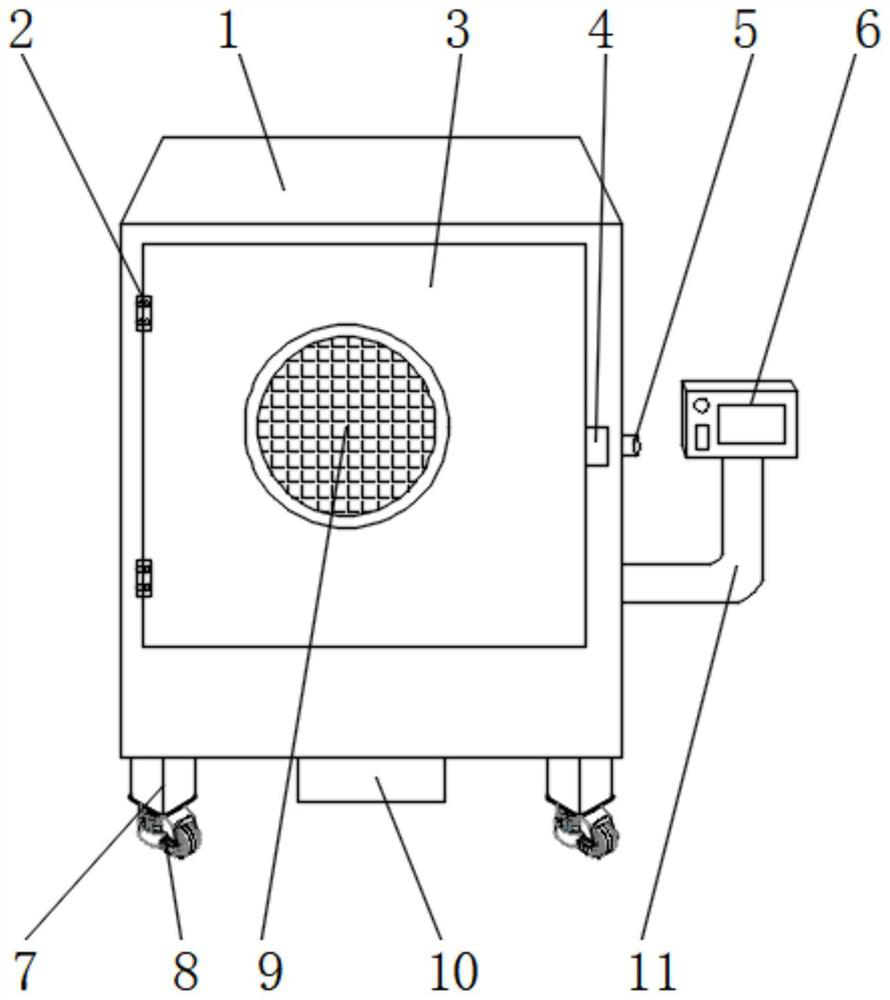

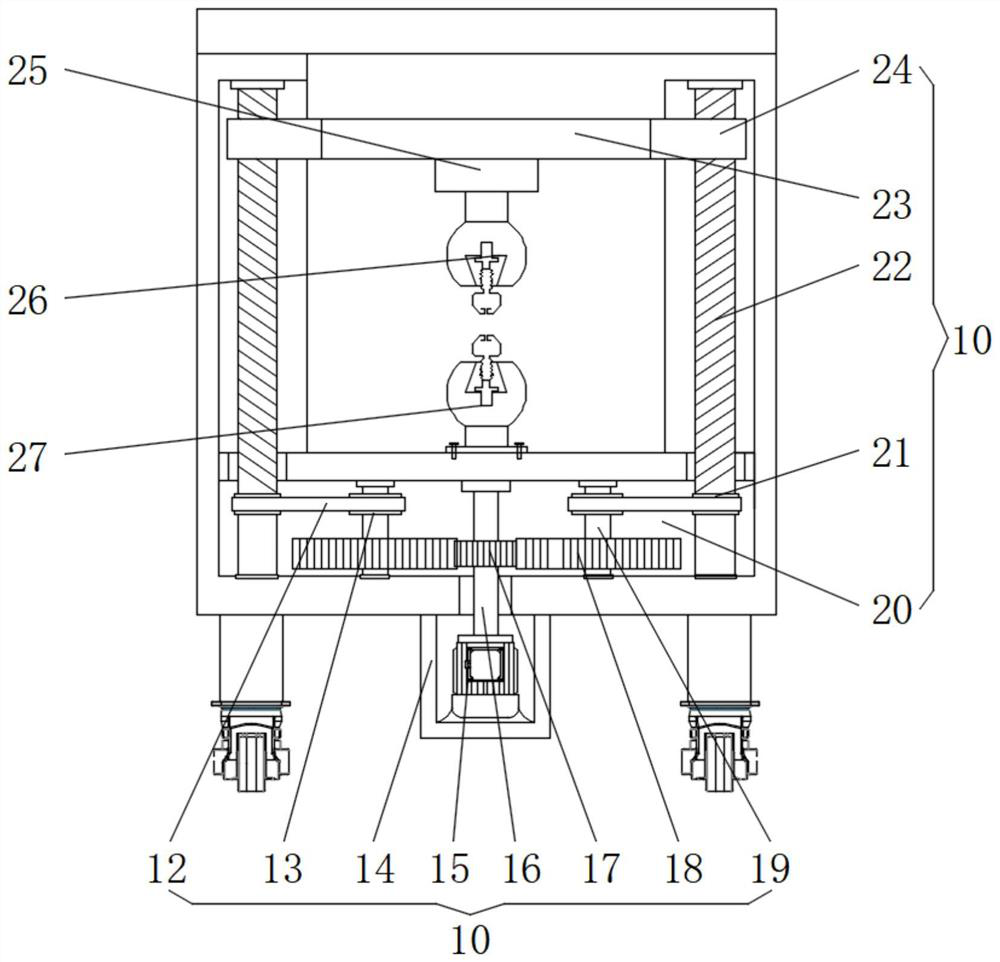

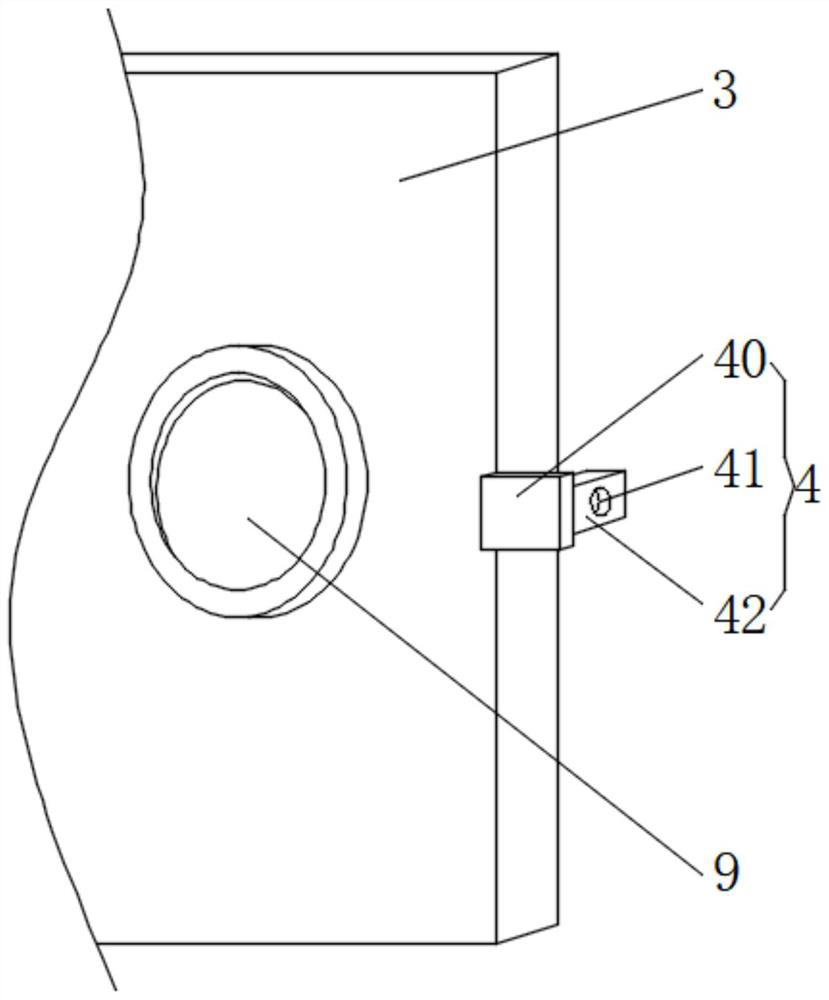

[0034] like Figure 1-7As shown, a detection device for the tensile strength of a cutter head and a method of using the same, comprising a device main body 1, the front end outer surface of the device main body 1 is provided with a protective door 3, and a protective door 3 is provided between the protective door 3 and the device main body 1. Page 2, the clip mechanism 4, the installation mechanism 5 and the eject mechanism 36, and the observation window 9 is provided in the middle of the outer surface of the front end of the protective door 3, and the tension sensor 25 is provided inside the device main body 1, and the outer surface of the lower end of the tension sensor 25 is provided. An upper chuck 26 is fixedly installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com