A laser particle size detection system of ink for digital printing

A laser particle size, digital printing technology, applied in particle size analysis, measuring device, particle and sedimentation analysis, etc., can solve problems affecting the convenience and efficiency of ink, splashing, ink spillage, etc., to improve convenience and efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

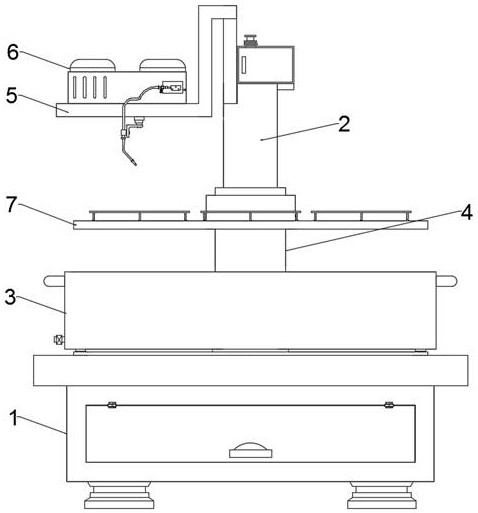

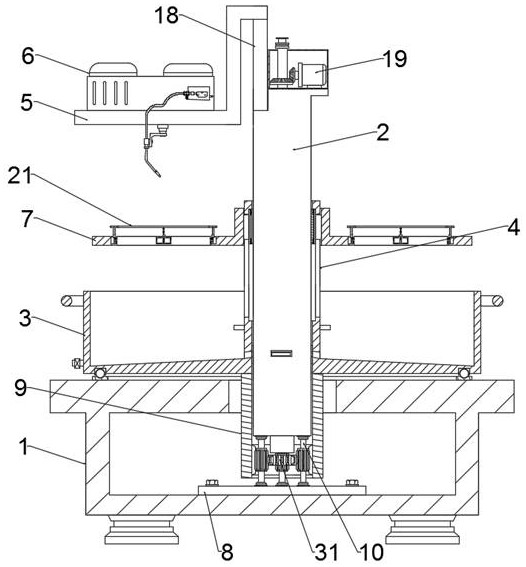

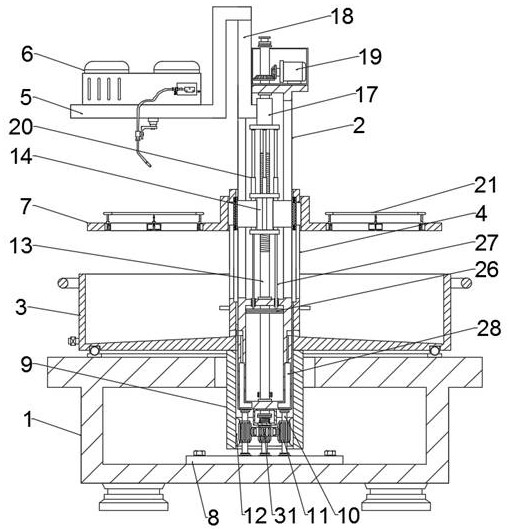

[0025] Example: see Figure 1-8 , an ink laser particle size detection system for digital printing, comprising a base 1, an installation port opened in the middle of the top surface of the base 1, a column 2 arranged inside the installation opening, a lifting plate 5 horizontally arranged on one side of the top of the column 2, and an installation The laser particle size detector 6 on the top of the lifting plate 5, the top surface of the base 1 is rotated horizontally, and there is a splash-proof plate 3 with an annular groove on the top surface. The bottom of the outer wall of one side is provided with a liquid outlet valve pipe communicating with the annular groove. The middle of the bottom surface of the splash plate 3 is vertically matched with the column 2 to open a through hole. The top of the through hole is vertically provided with a stabilizing cylinder 4, and the stabilizing cylinder 4. The movable sleeve is connected to the outer wall of the column 2; the upper out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com