Full-networking pipeline juice control system of small berry fermentation tank

A technology for fermentation tanks and small berries, which is applied in the field of fermentation tanks, can solve problems such as difficulty in adapting to the needs of large-scale and automated production of enterprises, a large number of labor requirements, and splashing of juice to the outside, so as to improve the efficiency of juice control and the environment. The effect of neatness and food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

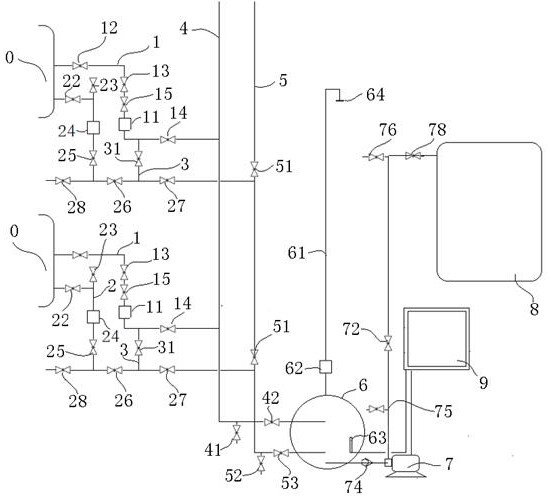

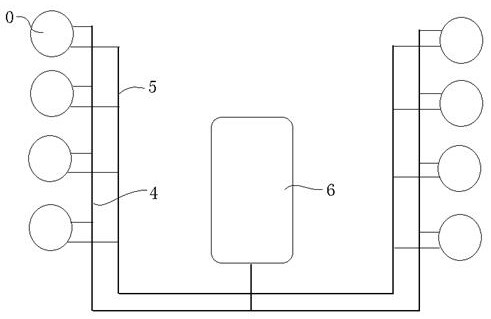

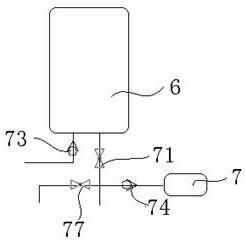

[0032] A fully networked pipeline juice control system for small berry fermentation tanks, which is connected between the liquid storage tank and multiple fermentation tanks to realize the synchronous collection, confluence and transportation of wine liquids in multiple tanks; it mainly consists of the separation juice pipeline system, control The juice pipeline system and the juice recovery system are composed of three parts. The separated juice pipeline system and the juice control pipeline system are set up according to the number of fermenters respectively, and each fermenter is equipped with a set of separated juice pipeline system and a set of juice control pipeline system, multiple sets of separated juice pipeline systems and multiple sets of The juice control piping system is eventually incorporated into the juice recovery system.

[0033]The separation juice pipeline system includes a separation pipeline 1 connected to the separation juice outlet of the fermenter 0 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com