Cutting apparatus with self-cleaning function in beef cattle slaughtering streamline

An assembly-line, self-cleaning technology, applied in slaughtering tools/knives, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems affecting the processing progress of the workstation, the workload of beef cattle, and inconvenient storage management, etc., to prevent Easy to scatter, rinse, prevent rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

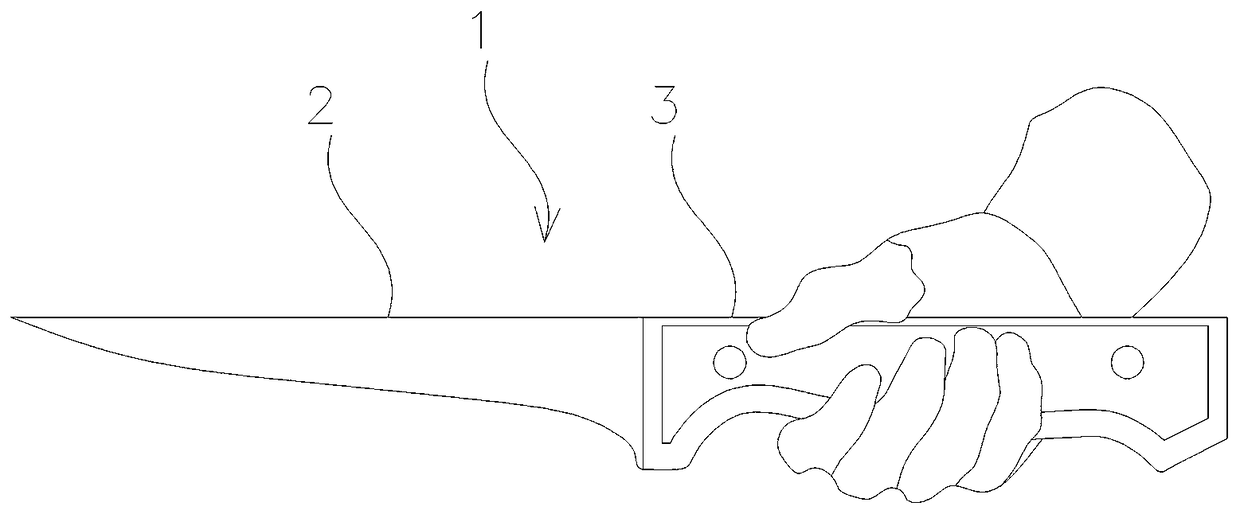

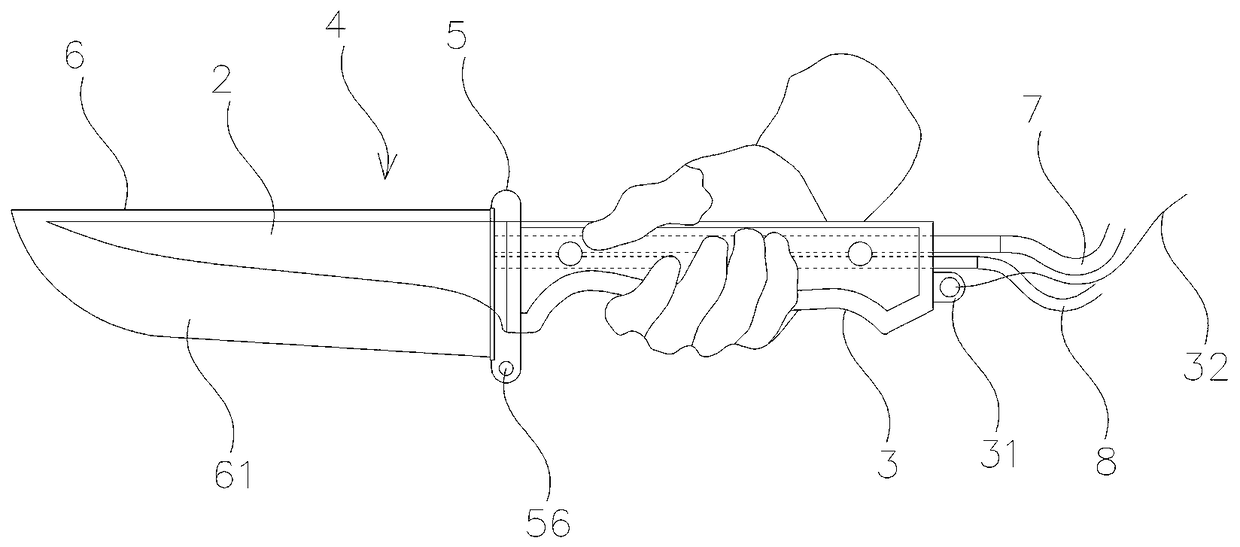

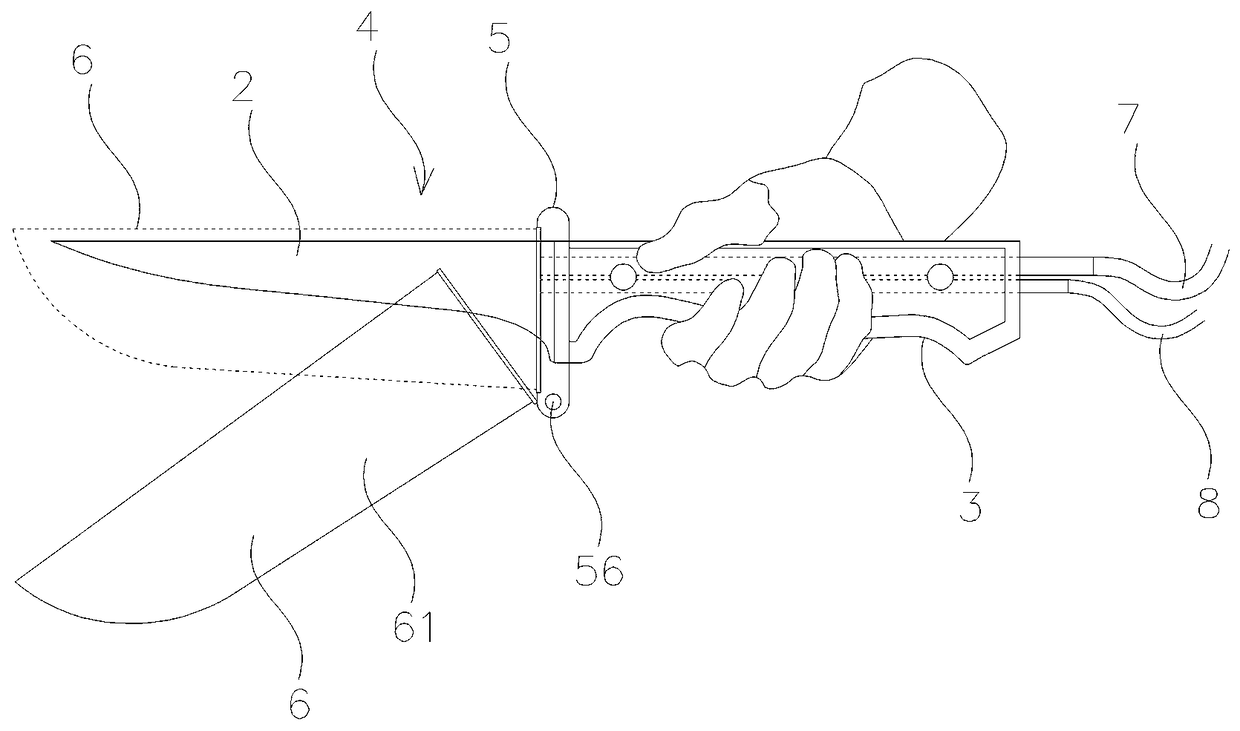

[0047] Such as Figure 1-7 As shown, a cutting device with self-cleaning function used in a beef cattle slaughter line is characterized in that:

[0048]The cutting device includes a cutter and a flushing device, the cutter includes a blade and a handle, the blade and the handle are connected as one, and the flushing device is assembled on the cutter to rinse the blade; The knives used in the slaughterhouse, in each station of the slaughtering line, use different types of knives for different operations, such as dividing knives, boning knives, multi-purpose knives, bloodletting knives, etc. There are differences in the shape of the blade, but they all have a long straight structure. The rear end is the handle and the front end is the blade. The blade is fixedly connected to the handle. The handle is equipped with an ergonomic arc structure for easy grip. The above knives can use the flushing device of the same specification, or design a flushing device of different specificat...

Embodiment 2

[0063] Such as Figure 9 , 10 As shown, on the basis of the above-mentioned embodiment, the side plate in this embodiment is provided with side wings on the vertical edge close to the fixed part, the two sides of the fixed part are provided with connecting grooves, and one side of the side wing is fixedly connected or flexibly connected with the side plate , and the other side is snap-connected with the connecting groove of the fixed part, and the side wings are used to assemble and fix the side plate that is turned over to form the handle guard on the fixed part. The side wings are triangular or trapezoidal, and the side wings are installed on the inner side of the side plate close to the vertical side of the fixing part, which does not affect the fitting of the side plate into the concave-convex groove. The buckle connection device between the side wing and the connection groove of the fixed part can be any known prior art, such as a snap spring is provided in the connectio...

Embodiment 3

[0065] On the basis of the above embodiments, the water inlet pipe in this embodiment is passed into the hot air, and the water outlet pipe is used to discharge the hot air, and the hot air enters the flushing chamber and is used to dry the blade. After the cutter is used, firstly send water into the water inlet pipe to clean the blade of the cutter; after that, connect the water inlet pipe to the external gas storage device or high-pressure gas generation and delivery device, and the outlet pipe to the sewage gas treatment pipeline , or empty, send hot air (hot air, or other gases) into the water inlet pipe, and dry the blade of the knife to prevent bacteria, secondary pollution, and metal knives from rusting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com