Packaging shell for containing uranium tetrafluoride container

A technology of uranium tetrafluoride and packaging shell, which is applied in the fields of uranium dioxide container and triuranium octaoxide to achieve the effect of guaranteeing technological advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

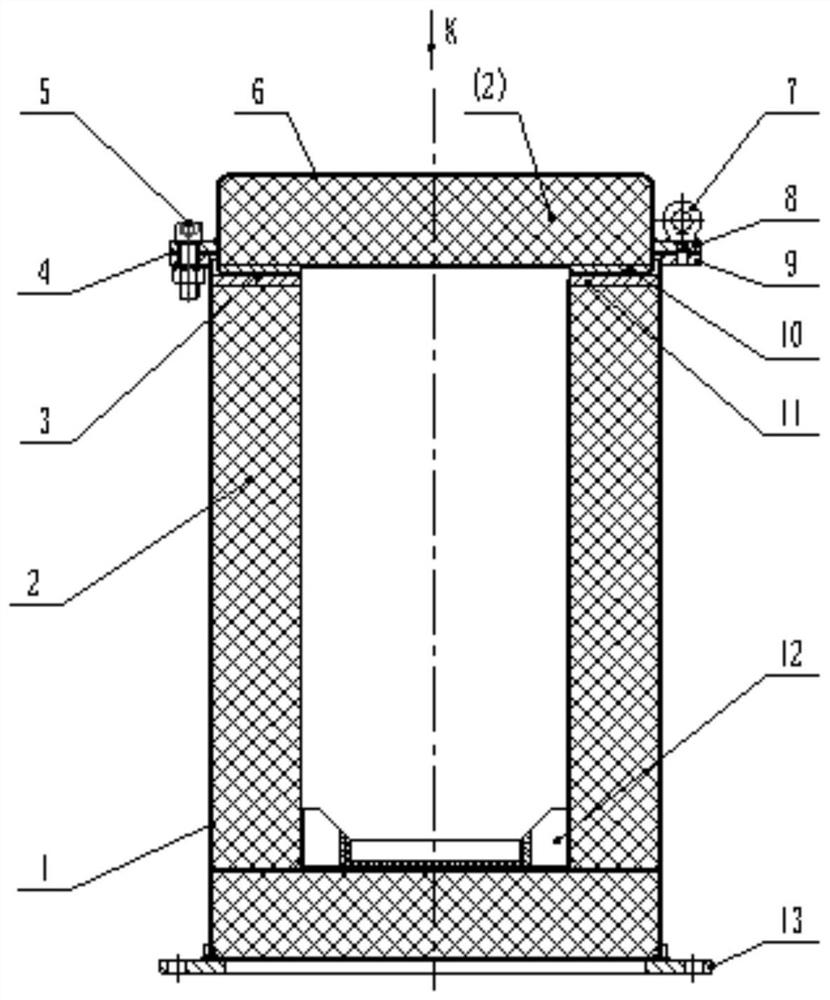

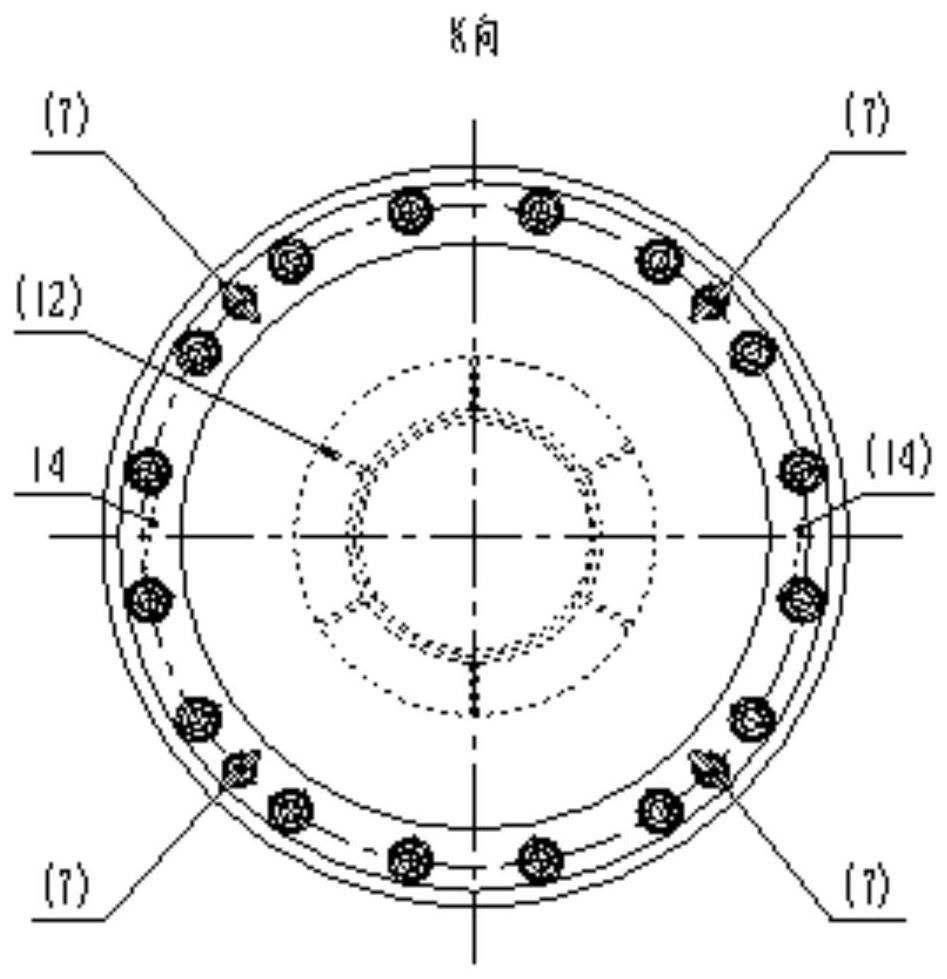

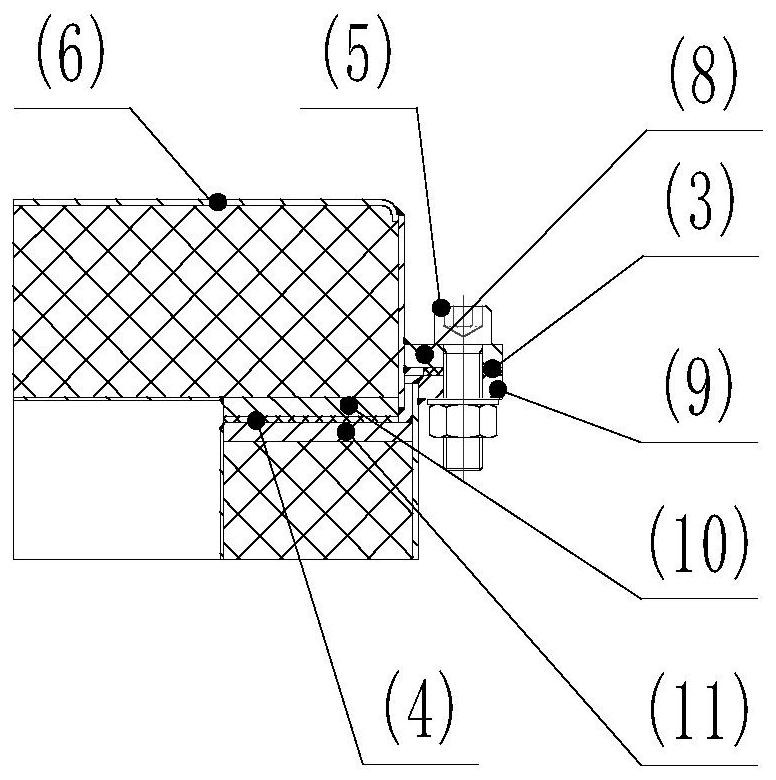

[0024] The packaging shell is cylindrical and consists of two parts: an upper shell 6 and a lower shell 1. The upper shell 6 and the lower shell 1 are hollow structures, both inside and outside are metal shells, and the interior is filled with 3# aluminum silicate fiber 2, 3# aluminum silicate fiber plays the role of buffering and heat insulation. The filling density of 3# aluminum silicate fiber in the upper and lower cladding is 180±15%kg / m 3 .

[0025] When filling, the aluminum silicate fiber is cut into circular plates or circular rings according to the filling area, and then laminated into the filling area one by one. Partial discontinuous areas are filled with loose blankets. Each layer of aluminum silicate fiber blanket is pressed into a special layer. After the tool is compacted and filled, the parts are weighed to ensure that the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com