Direct-current brushless motor of electric tool

A brushless DC motor and power tool technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of complex production, low efficiency, large torque of the outer rotor structure, etc., and achieve the effect of improving the output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

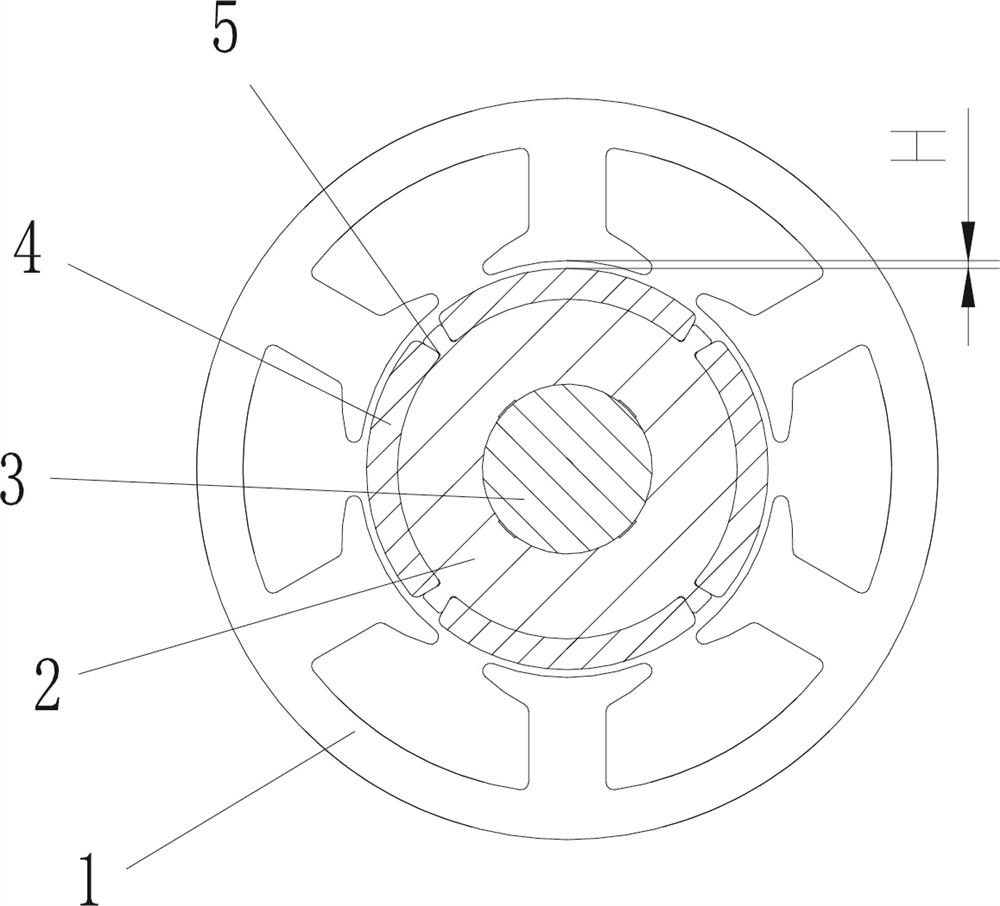

[0022] like figure 1 As shown in the figure, a brushless DC motor of an electric tool is used for the operation of non-magnetic materials to be processed, and specifically includes: a stator 1 for fixing on the inner wall of the electric tool casing, and a stator 1 sleeved However, the rotor cores 2 are not in contact with each other. The rotor core 2 is composed of silicon steel sheets. The stator 1 includes a stator core and a stator winding. A rotating shaft 3 is installed on the rotor core 2. The rotating shaft 3 passes through The bearing is fixed on the body of the electric tool. Further, the peripheral outer wall of the rotor core 2 is provided with a plurality of dovetail arc grooves 4, and the arc magnetic steel 5 is fixedly installed on the dovetail arc groove 4, so that it cannot follow the diameter of the rotor core 2. to disengage. Preferably, the angle between one side of the dovetail arc groove 4 is 80°. In this way, the minimum gap H between the arc-shaped m...

Embodiment 2

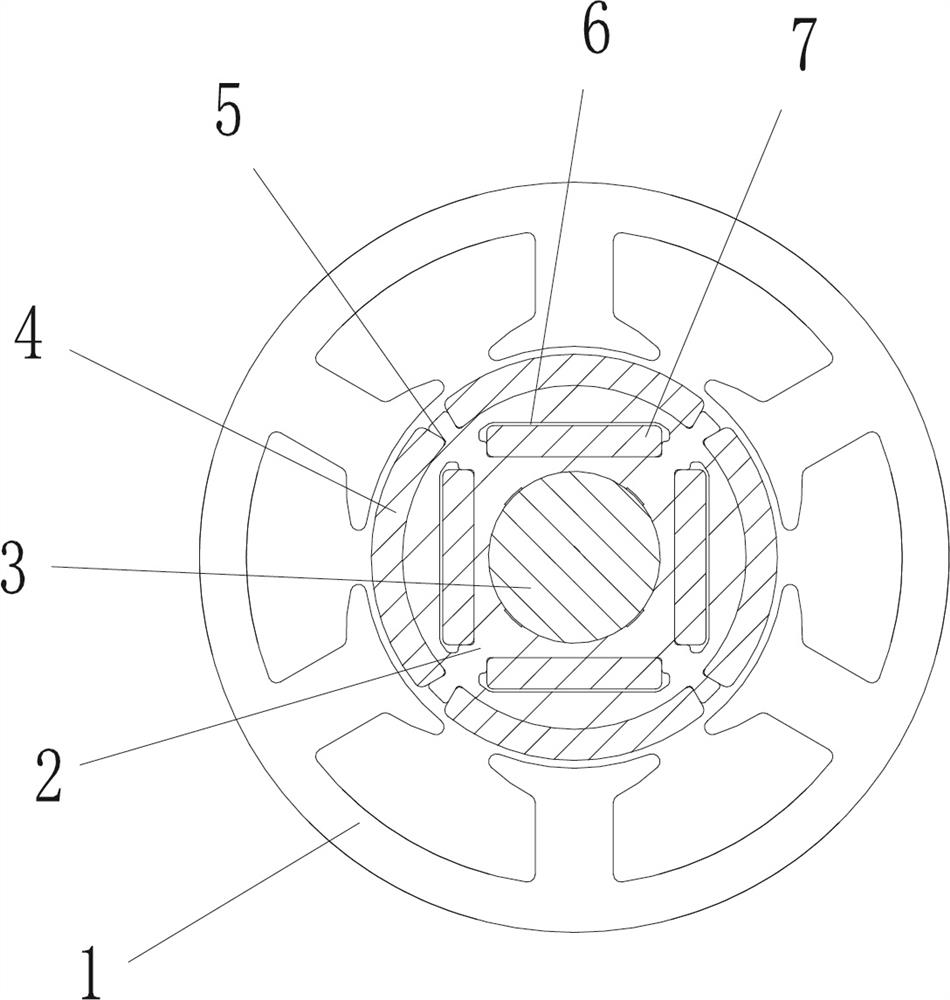

[0024] like figure 2 As shown, this embodiment further proposes a reinforced rotor structure. Specifically, on the basis of implementation 1, the rotor core 2 is further provided with a plurality of second limit slots 6. The second limit A rectangular magnetic steel 7 is arranged in the slot 6 , and the rectangular magnetic steel 7 is located between the rotating shaft 3 and the arc-shaped magnetic steel 5 . Preferably, the number of rectangular magnetic steels 5 is 4 and uniformly distributed in a ring shape, forming a substantially square shape that is not in contact. Similarly, according to the torque formula M=F1×L1+F2×L2, the torque can be increased by at least 25% under the condition of the same diameter rotor.

Embodiment 3 Embodiment 4

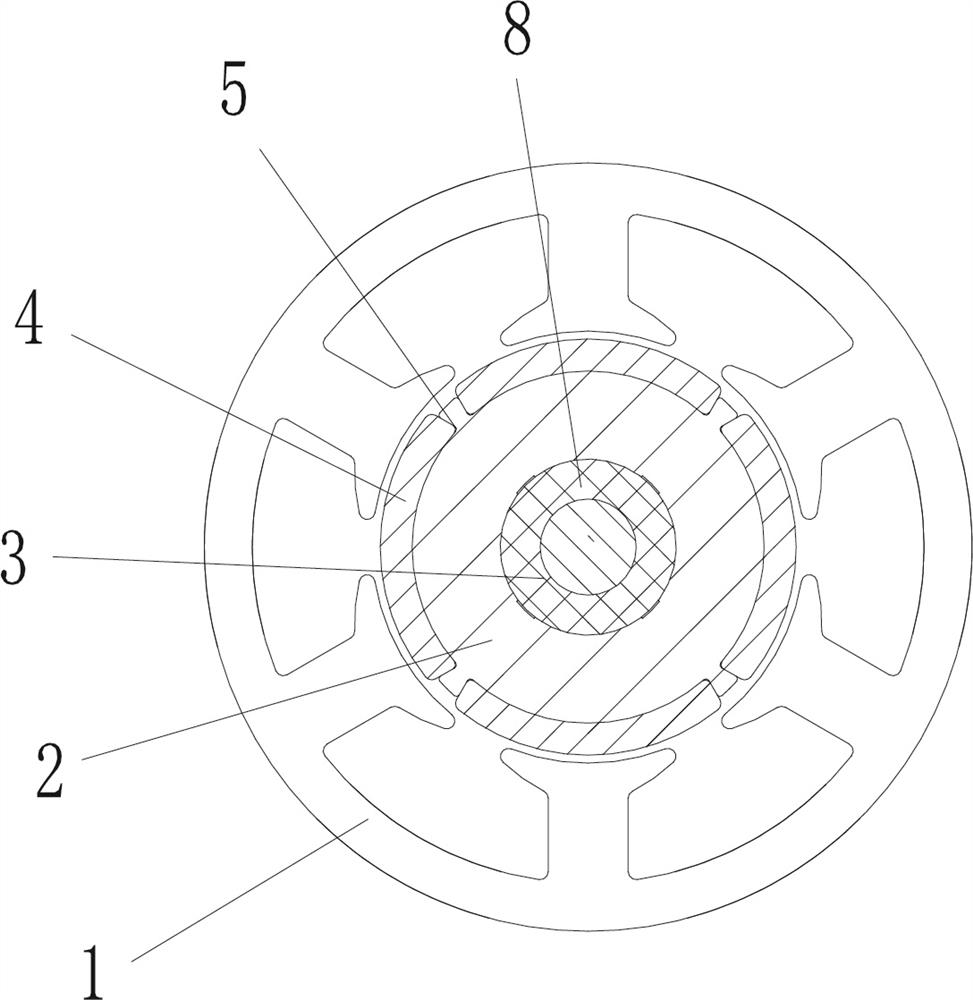

[0026] In the motor used in electric tools, ineffective eddy current will be generated during the operation of the motor, and the eddy current will generate ineffective heat, which will lead to abnormal heat generated by the motor. After the motor heats to a certain extent, the efficiency will drop or the insulating layer will be damaged, reducing the load resistance of the motor. . In order to overcome this defect, on the basis of implementing the first and second embodiments, such as Figure 3-4 As shown, the third embodiment and the fourth embodiment are further proposed, and a fixed insulating layer 8 is respectively provided between the rotating shaft 3 and the rotor core 2 .

[0027] According to the above, no matter which method is adopted, the torque of the motor and the output ratio of the motor have been increased. If the cost needs to be reduced, according to the torque formula M value under the same conditions as the existing inner rotor in the market, the perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com