Injection molding system

A technology of injection molding and injection port, which is applied in the field of injection molding systems, can solve the problems of poor appearance and poor molding of injection molded products, and achieve the effects of inhibiting poor molding, inhibiting the formation of resin coatings, and improving the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings and the like.

[0028] (Structure related to the helical groove 41 of the shaft 40)

[0029] First, the structure, action, effect, and the like related to the helical groove 41 of the shaft 40 will be described.

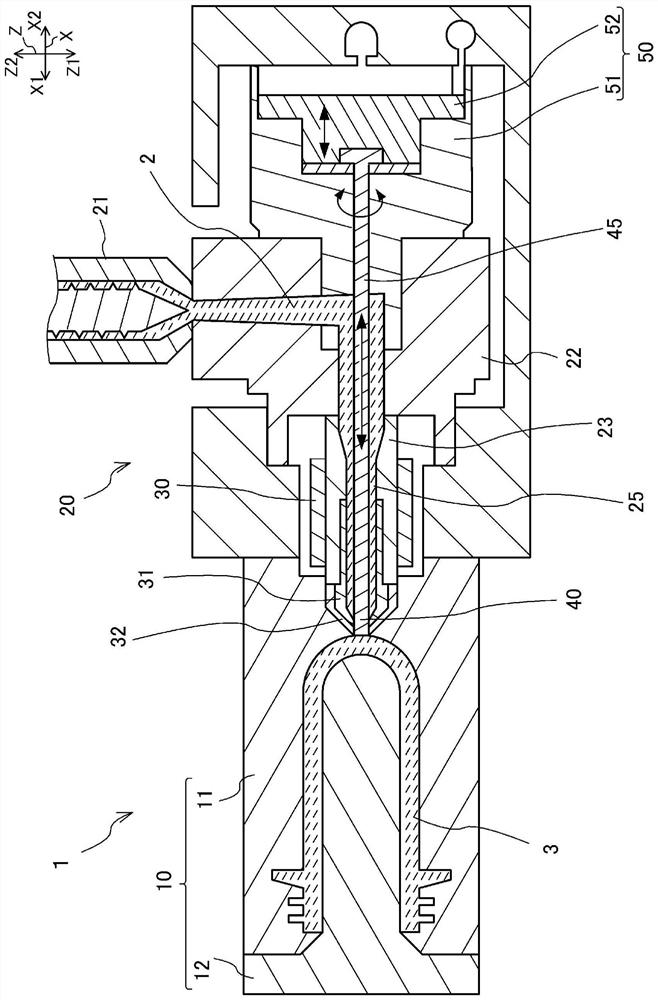

[0030] figure 1 It is a longitudinal cross-sectional view explaining the whole structure of the molding system 1 of embodiment.

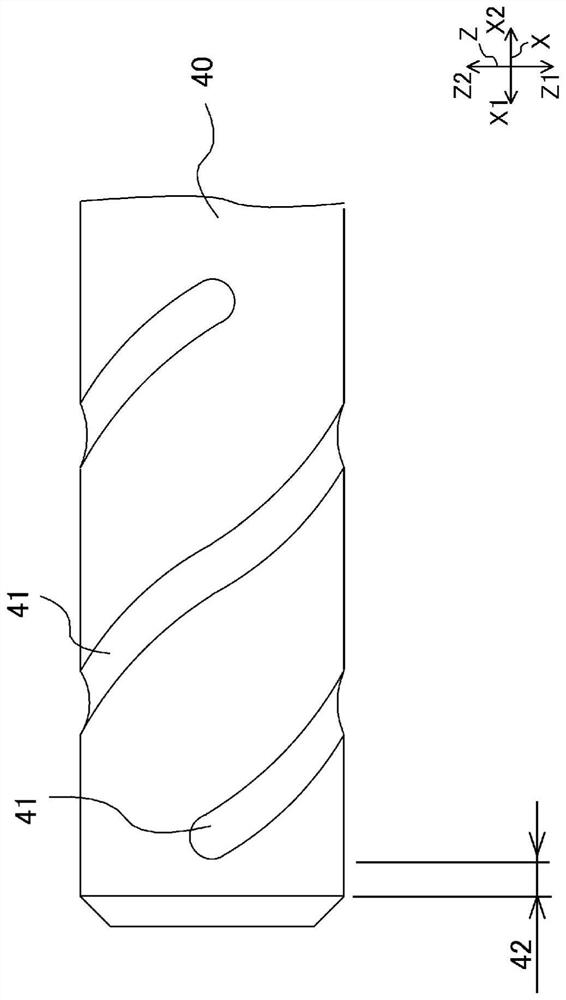

[0031] figure 2 This is an external view of the vicinity of the distal end of the shaft 40 .

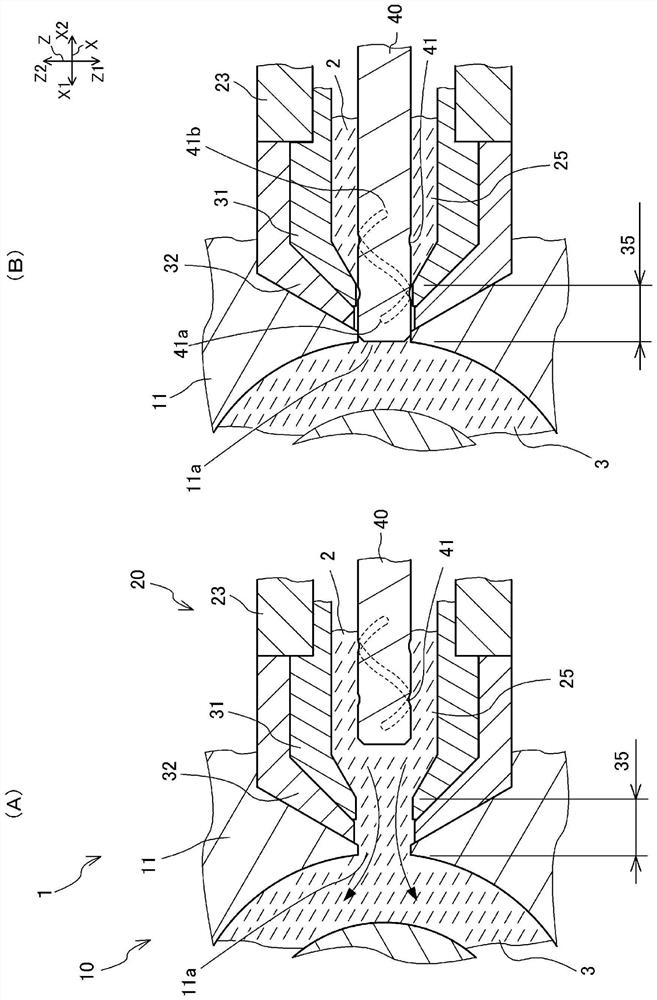

[0032] image 3 It is a longitudinal cross-sectional view explaining the structure of the connection hole 35 vicinity of the molding system 1 of embodiment.

[0033] image 3 (A) is a diagram explaining a state in which the tip of the shaft 40 is retracted / receded from the connection hole 35 and a state in which the molten resin is injected into the mold.

[0034] image 3 (B) is a diagram illustrating a state in which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com