Mine water reuse system and backwashing method thereof

A mine water and backwashing technology, which is applied in the direction of separation methods, chemical instruments and methods, and industrial water supply conservation, etc., can solve the problems of insufficient washing out of coal slime, poor backwashing effect, and sand running.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

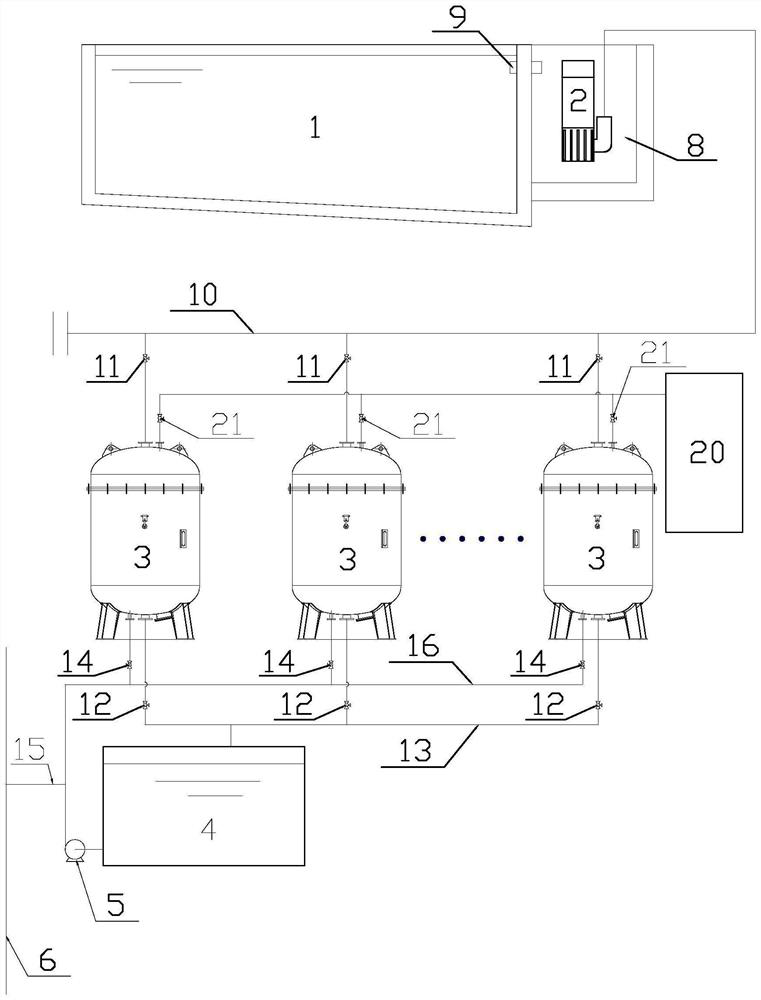

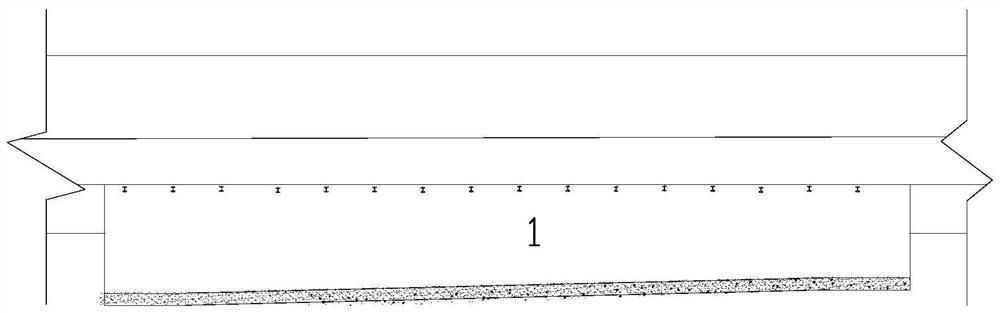

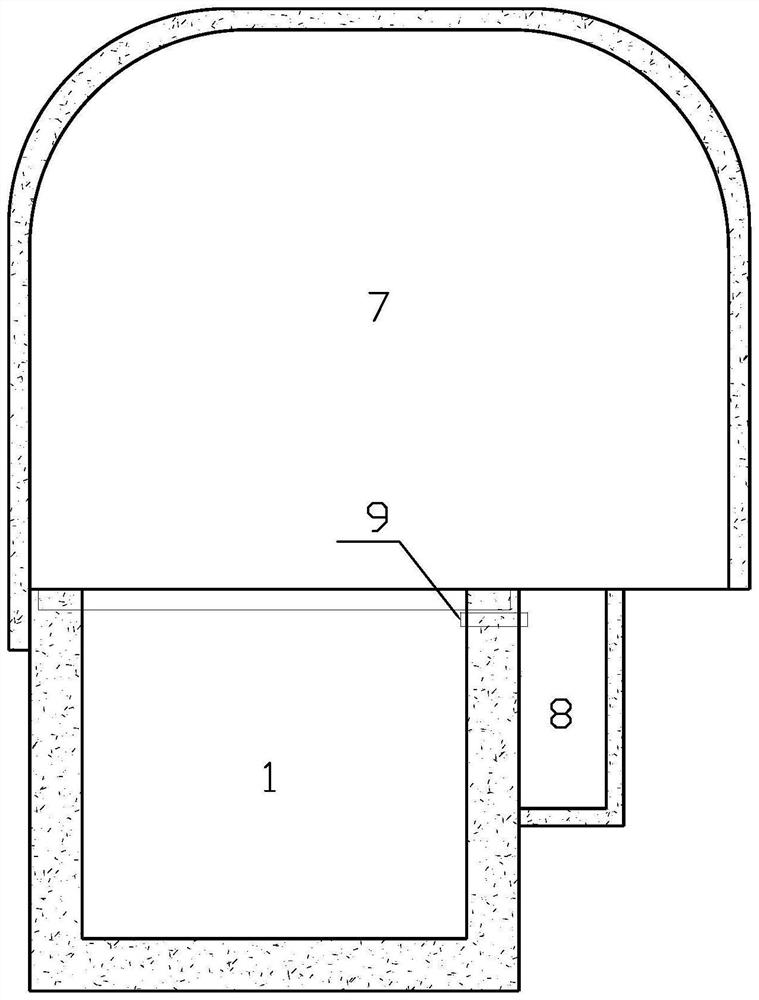

[0031] Implementation mode one: if Figure 1-9 As shown, the mine water reuse system of the present invention includes a raw water pool 1, a raw water pump 2, N filter tanks 3, a clean water tank 4, a water supply pump 5 and a water supply pipe network 6, and the raw water pool 1 is arranged in an underground roadway 7 Inside, an overflow tank 8 is provided on the downstream side of the raw water pool 1, and an overflow pipe 9 is provided between the overflow tank 8 and the raw water pool 1. The raw water pump 2 is a submersible pump, and the raw water pump 2 is arranged on the overflow In the tank 8, the top of each filter tank 3 is provided with a water inlet and a recoil outlet, and the bottom of each filter tank 3 is respectively provided with a water outlet and a recoil inlet, and the water inlet of each filter tank 3 passes through the water inlet pipe 10 and The water inlet valve 11 on the water inlet pipe 10 communicates with the outlet of the raw water pump 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com