Granulation equipment for chemical fertilizer processing and method thereof

A technology for granulating equipment and chemical fertilizers, which is applied in the direction of climate change adaptation, extrusion and granulation of raw materials, etc., can solve the problems of inconvenient disassembly of the granulation plate, complicated disassembly and assembly steps of the granulation plate, inconvenient to replace the granulation plate, etc. The effect of replacement or cleaning, disassembly and assembly is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

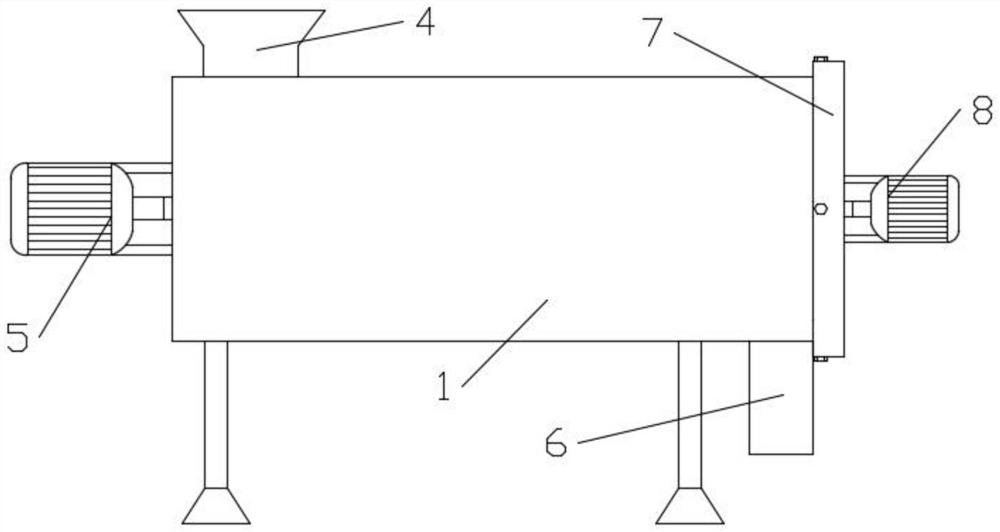

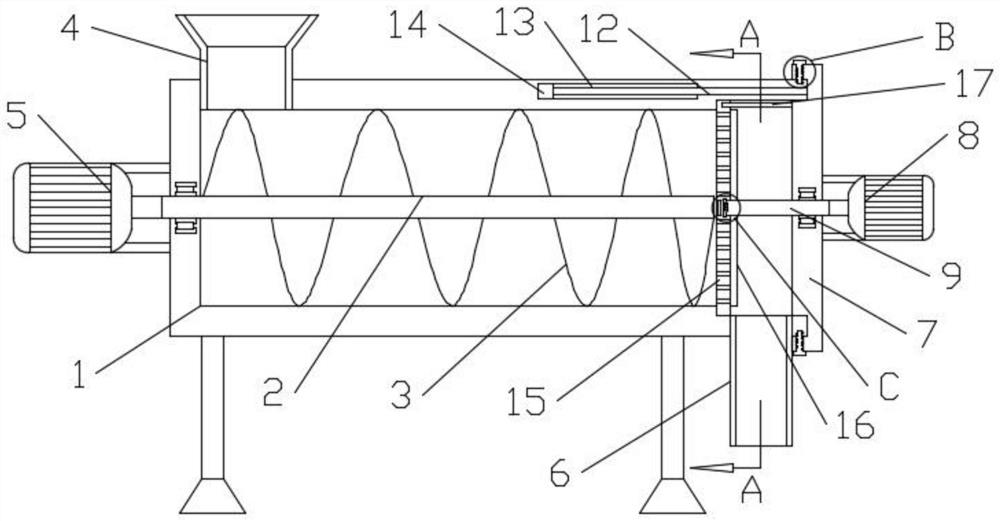

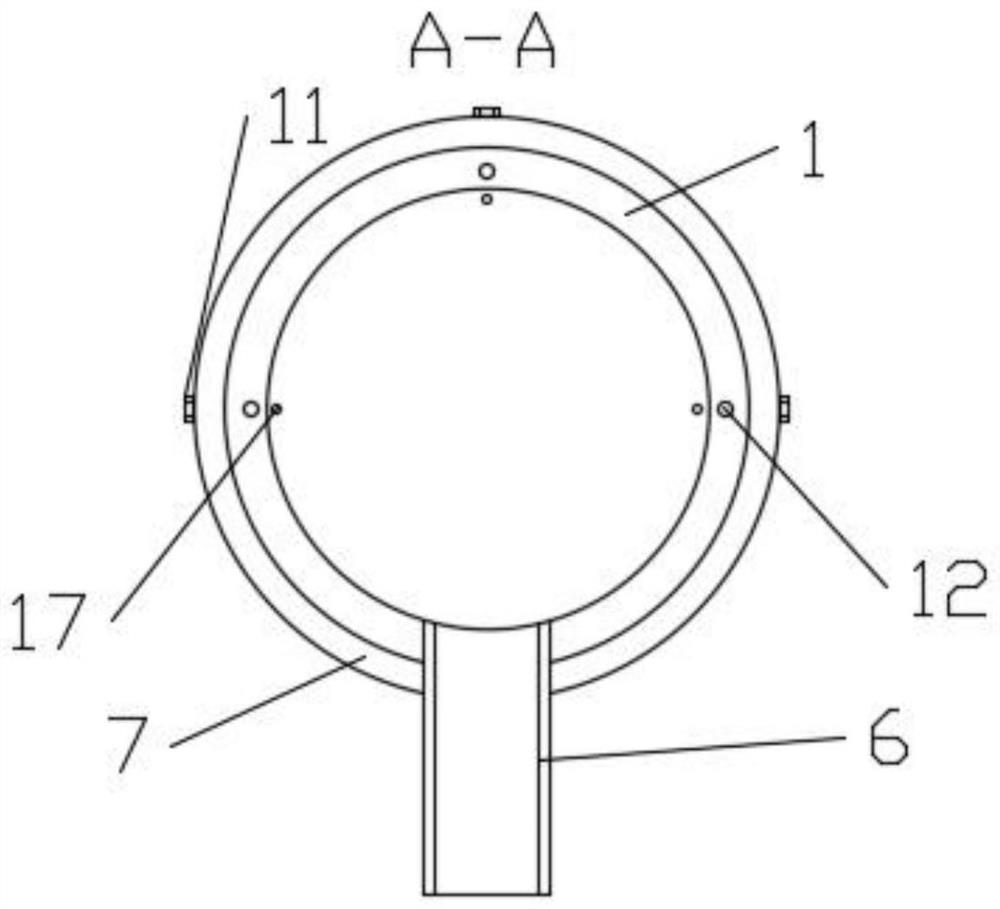

[0028] Refer to attached Figure 1-6 A kind of granulation equipment for chemical fertilizer processing provided by the present invention comprises a box body 1, a conveying assembly is arranged in the box body 1, and a granulation plate 15 is provided, and the granulation plate 15 is slidably arranged in one end of the box body 1, and the box body 1 The end of the body 1 close to the granulation plate 15 is detachably installed with a cover plate 7 through four sets of bolts 11, and a cutting mechanism is installed on the cover plate 7. The top and both sides of the end close to the cover plate 7 of the box body 1 are equipped with telescopic components. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com