Transmission system of embroidery machine and embroidery machine thereof

A transmission system and embroidery machine technology, applied in the field of embroidery machines, can solve problems such as thread breakage, needle breakage, and shuttle bed coordination errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

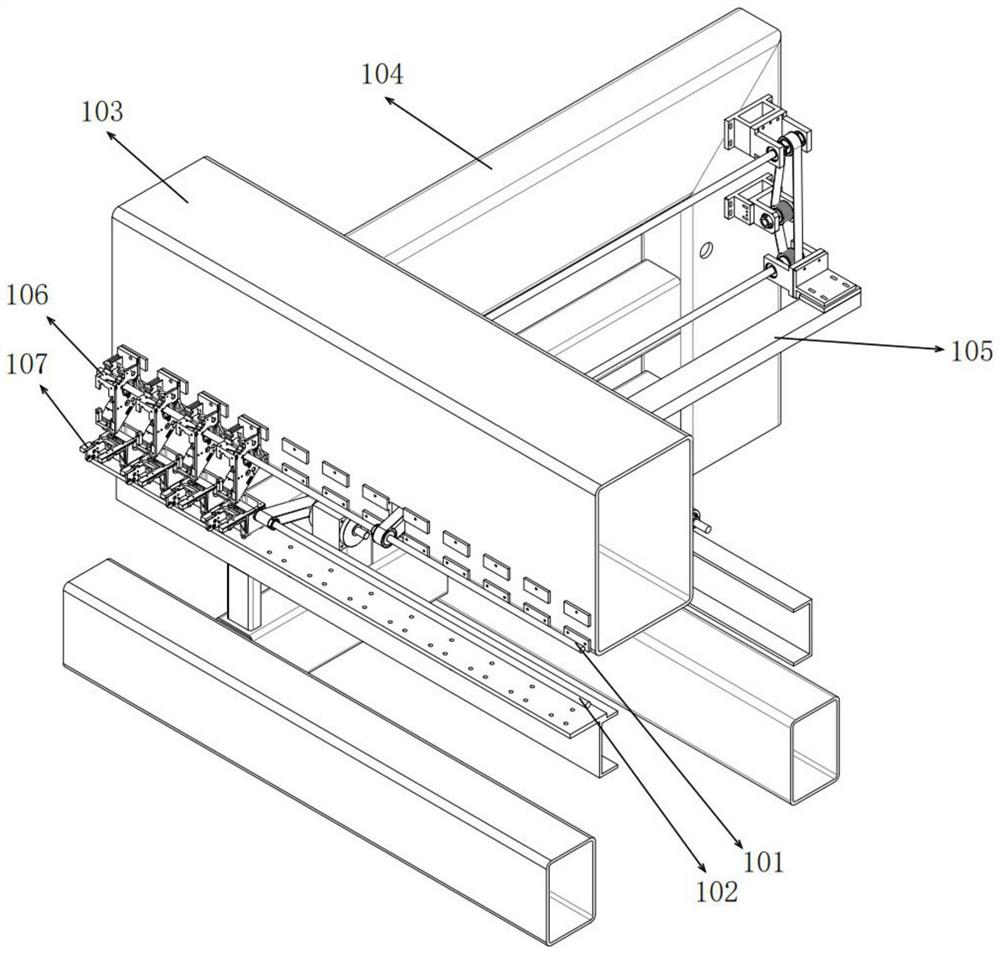

[0030] This embodiment provides a transmission system of an embroidery machine, please refer to figure 1 As shown, the embroidery machine includes an upper shaft 101, a lower shaft 102, a girder 103, a backpack frame 104, a frame 105, a number of machine heads 106 and a number of shuttle machines 107. In order to facilitate the demonstration of the transmission system of this embodiment, the figure is omitted. Part of the machine head and shuttle bed were removed.

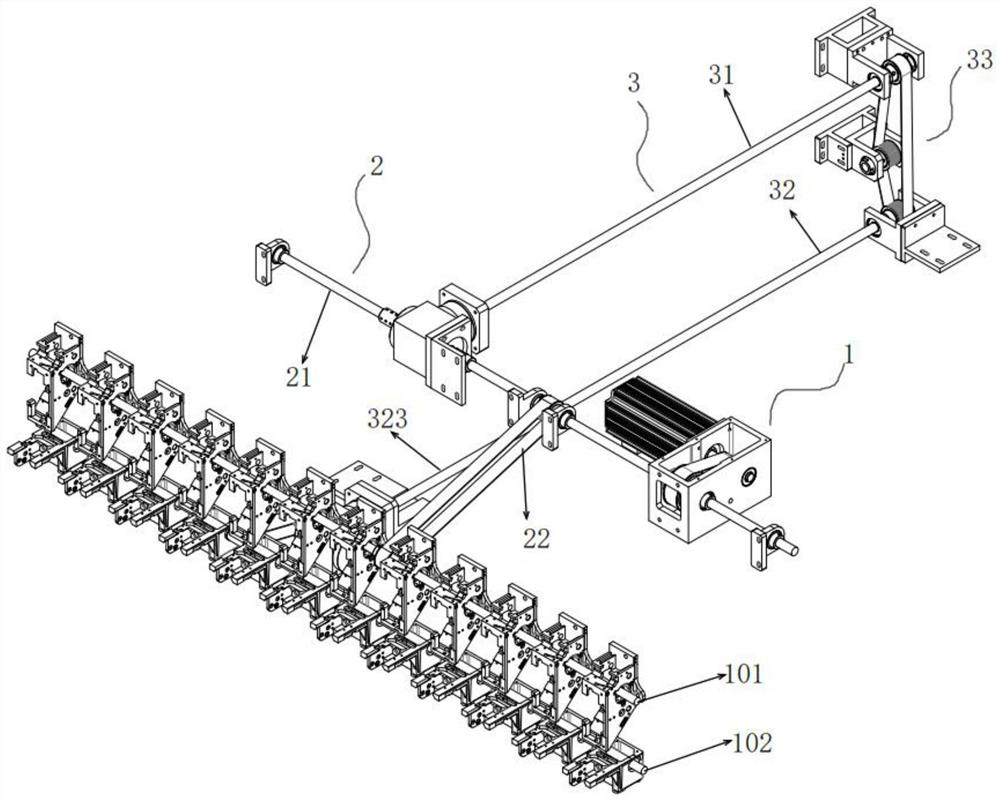

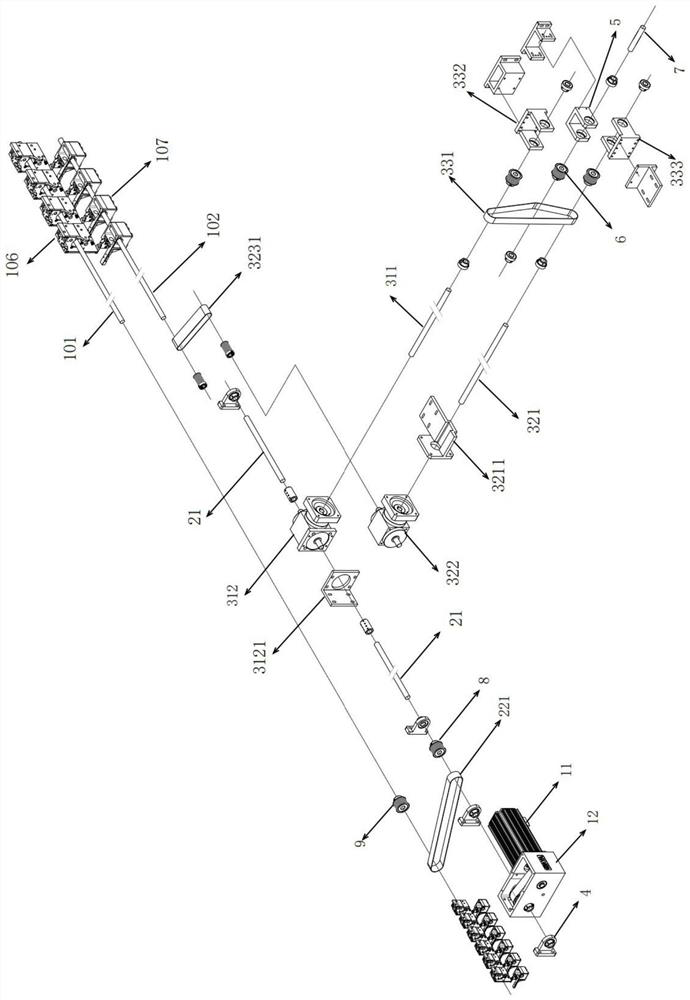

[0031] The following focuses on the transmission system of this embodiment. Please refer to figure 2 As shown, in order to facilitate the display of the transmission system, structures such as the girder, the backpack frame, the frame, etc. are omitted in the figure. The transmission system includes a driving part 1, a first transmission part 2 and a U-shaped transmission part 3. The driving part 1 and the first The transmission member 2 is drivingly connected, the first transmission member 2 and the U-shaped tra...

Embodiment 2

[0042] like Figure 5 As shown, this embodiment provides a transmission system for an embroidery machine. The difference from Embodiment 1 is that the second transmission member 31 includes a fourth belt 313, the third transmission member 32 includes a fifth belt 324, and the second belt assembly 33 It includes a second belt 331 and a belt transmission case 334. The belt transmission case 334 is respectively provided with a fourth transmission shaft 3341 and a fifth transmission shaft 3342. The fourth belt 313 is connected to the first transmission shaft 21 and the fourth transmission shaft 3341 through the pulley The fifth belt 324 is connected to the lower shaft 102 and the fifth transmission shaft 3342 through pulleys, respectively, and the second belt 331 is connected to the fourth transmission shaft 3341 and the fifth transmission shaft 3342 through the pulleys.

[0043] In this embodiment, the fourth belt 313 and the fifth belt 324 are also provided with a belt tensionin...

Embodiment 3

[0047] This embodiment provides an embroidery machine. The embroidery machine is installed with the transmission system of the embroidery machine in Embodiment 1 or Embodiment 2. The transmission system of the embroidery machine has been described in detail in Embodiment 1 or Embodiment 2. , which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com