Wire clamp for electric power circuit wire

A technology for power lines and wire clips, which is applied to overhead lines/cable equipment, etc., can solve the problems of easily damaged ropes, easy to slide, and ropes that cannot be fixed at a fixed point, so as to achieve the effect of modularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

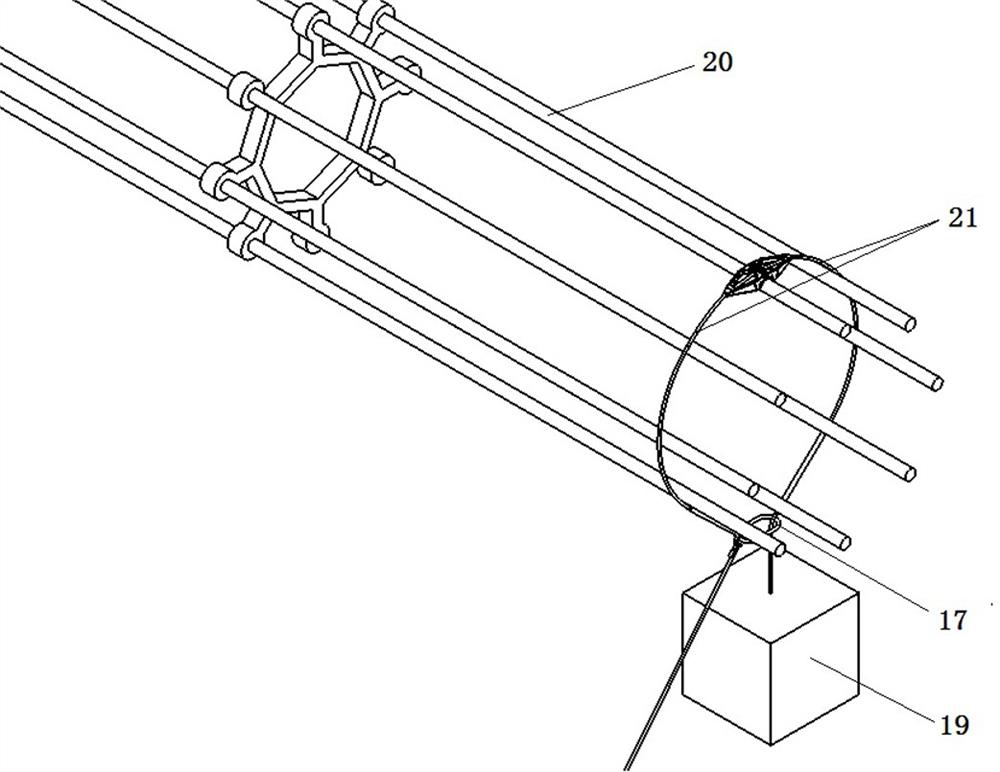

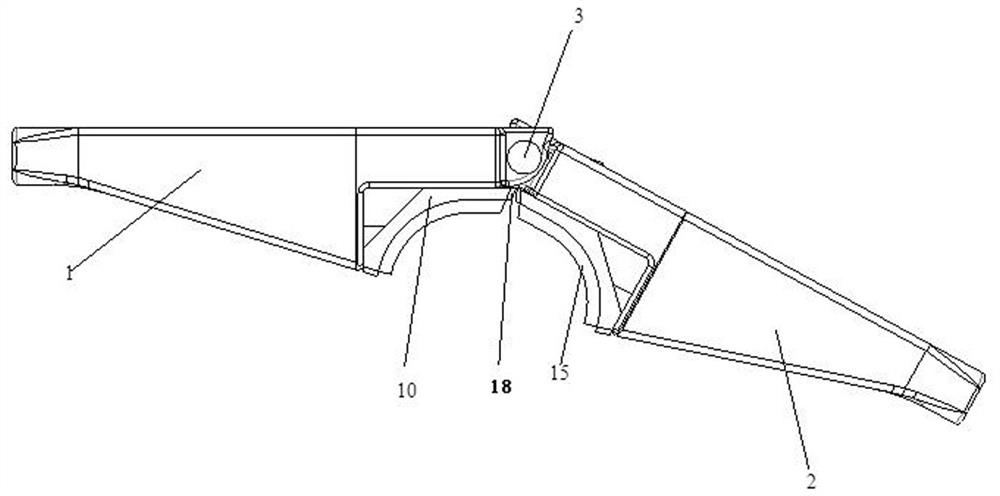

[0037] as Figure 1-Figure 5 As shown, the present embodiment provides a power line wire clamper, comprising a left clamp support frame 1, a right clamp support frame 2 and a sandwich module for clamping the wire 20, the left clamp support frame 1 and the right clamp support frame 2 are connected by rotation of the hinge 3, the hinge 3 jacket has an elastic reset device, the left clamp module and the right clamp module relative to the axis 3 symmetrical setting, the left clamp support frame 1 and the right clamp support frame 2 are provided with a through hole for the static rope 21 to pass through 4, The clamp module is located on the downward one side of the left sandwich support frame 1 and the right clamp support frame 2.

[0038] Wherein, the left sandwich support frame 1 and the right sandwich support frame 2 of the present embodiment

[0039]Left sandwich support frame 1 and right sandwich support frame 2 are hollow design, left sandwich support frame 1 and right clamp suppo...

Embodiment 2

[0049] as Figure 6 、 Figure 7 As shown, the present embodiment provides a power line wire clamper, comprising a left clamp support frame 1, a right clamp support frame 2 and a clamp module for clamping the wire, the left clamp support frame 1 and the right clamp support frame 2 are connected by the rotation of the hinge 3, the hinge 3 jacket has an elastic reset device, the left clamp module and the right clamp module are symmetrically set relative to the shaft 3, the left clamp support frame 1 and the right clamp support frame 2 are provided with a through hole for the static rope 21 to pass through 4, The clamp module is located on the upper and lower symmetrical sides of the left sandwich support frame 1 and the right clamp support frame 2. The connecting surface of the left sandwich support frame 1 and the right clamp support frame 2 is provided with a notch at both ends, the clamping module comprises a clamping module 10, the clamping module 10 is fixed within the notch.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com