Raw material casting device for electric vehicle hub

A technology for electric vehicles and wheel hubs, applied in the field of wheel hub casting, can solve the problems of unqualified wheel hub quality, wheel hub quality problems, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

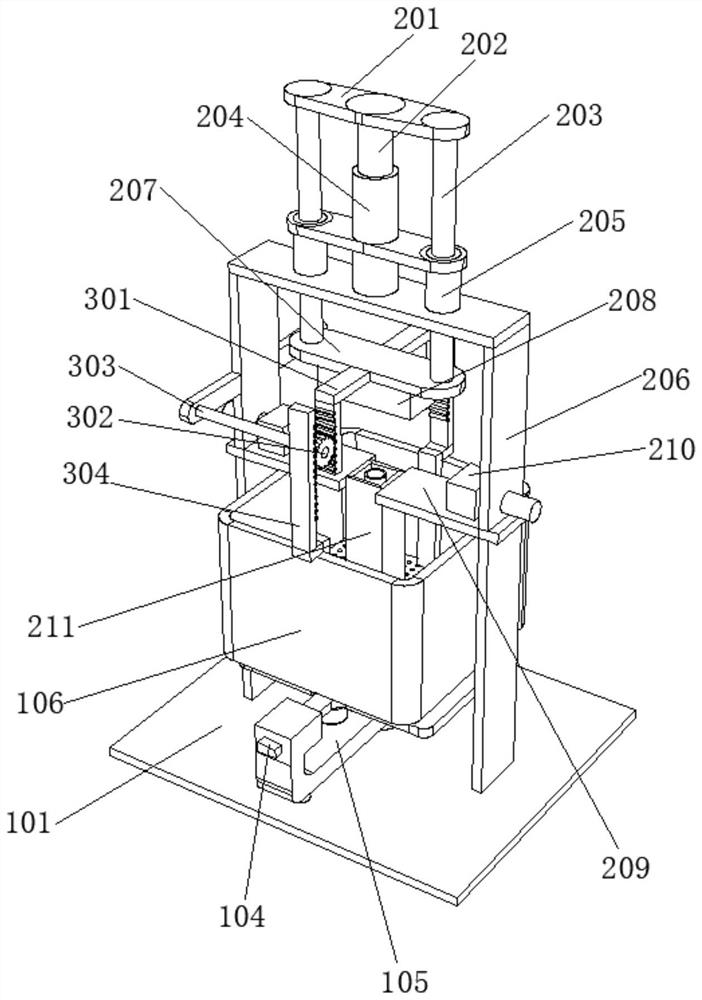

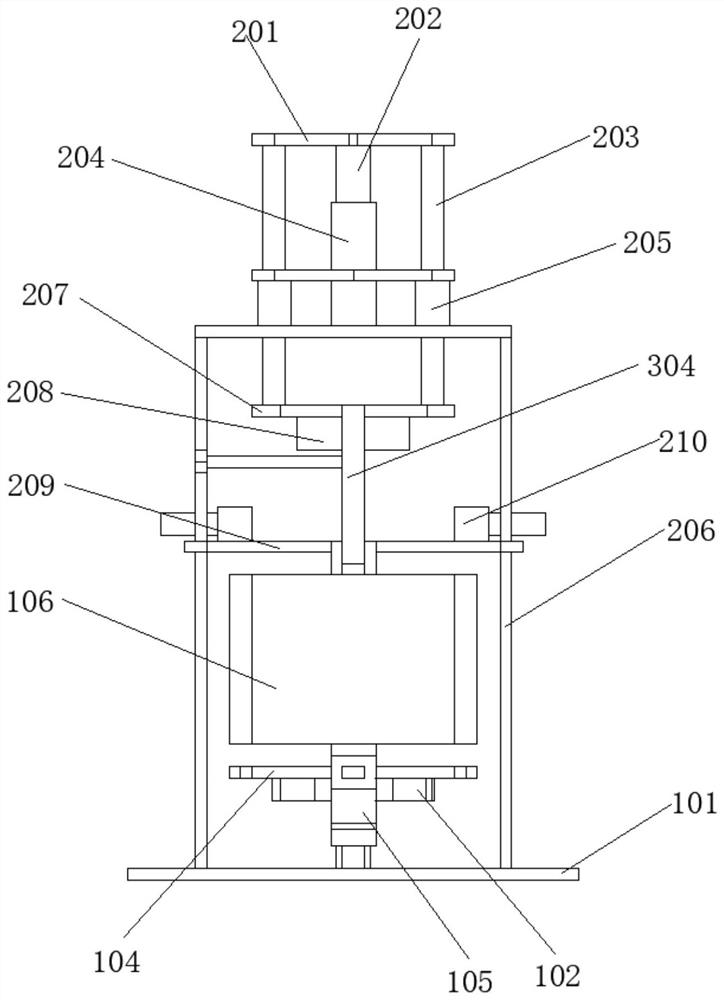

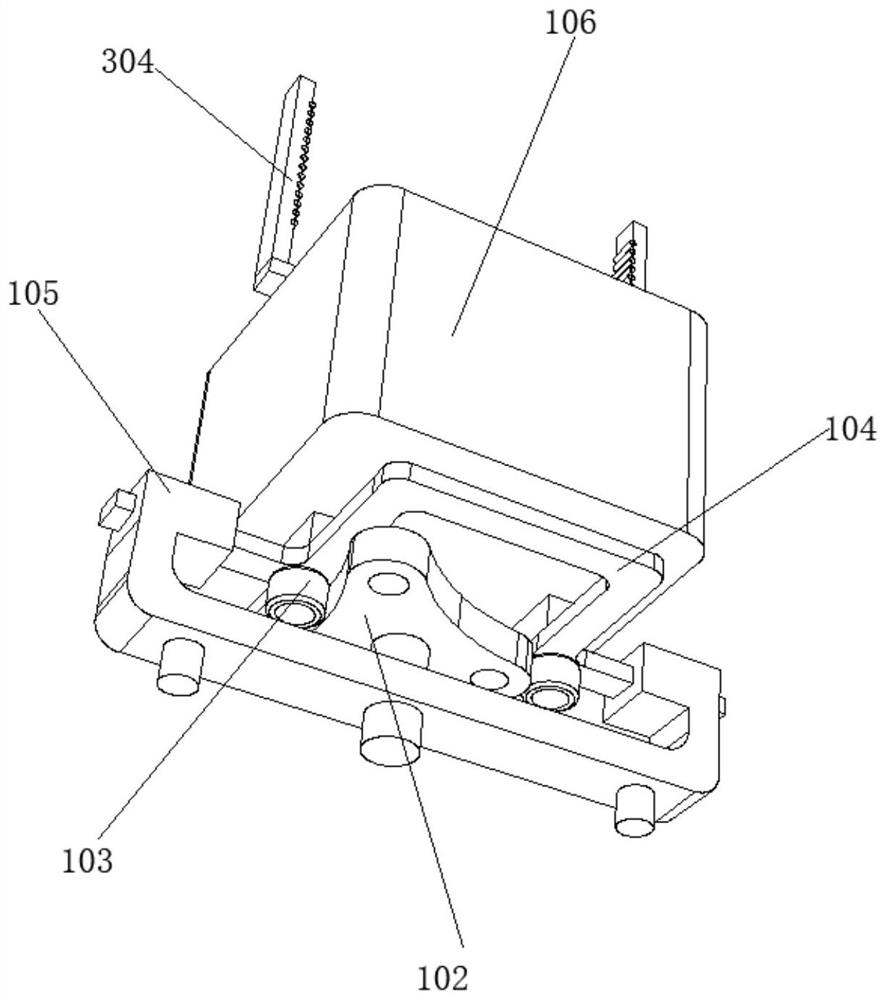

[0030] see Figure 1 to Figure 5 , a raw material casting device for an electric wheel hub, including a base plate 101, the base plate 101 is fixedly connected with the limit block 105 and the outer frame 206, and is hinged with the end of the rotating block 102 away from the driven block 104, and the base plate 101 defines the outer frame 206 and the outer frame 206. The position of the rotating block 102 and other structures; the bottom plate 101 is provided with a rotating block 102, the size of the rotating block 102 matches the distance between the two rollers 103, and the rotating block 102 starts to rotate under the drive of the motor, so that the roller 103 and the slave The position of the moving block 104 is changed;

[0031] The side of the rotating block 102 is provided with rollers 103, the number of the rollers 103 is two, the two rollers 103 are located on both sides of the rotating block 102, one side of the roller 103 is fixedly connected with the driven block...

Embodiment 2

[0034] see figure 1 , figure 2 and Image 6 , a raw material casting device for an electric wheel hub, comprising a pressing block 201, the lower part of the pressing block 201 is fixedly connected with the pneumatic rod 202 and the driven rod 203, and the operator pushes the pneumatic rod 202 and the driven rod 203 by pressing the pressing block 201. Start to move; a pneumatic rod 202 is fixedly connected to one side of the pressing block 201 , the size of the pneumatic rod 202 matches the groove opened in the air pressure chamber 204 , and the pneumatic rod 202 cooperates with the air pressure chamber 204 to limit the downward pressure of the driven rod 203 extent and final position;

[0035] Both ends of one side of the pressing block 201 are fixedly connected with driven rods 203. The number of the driven rods 203 is two. The two driven rods 203 are axially symmetrically distributed with the pneumatic rod 202 as the symmetry axis. Matching with the through hole opened ...

Embodiment 3

[0041] see figure 1 , figure 2 , Image 6 and Figure 7 , a raw material casting device for an electric wheel hub, including a rack 301, the rack 301 starts to move under the driving of the connecting block 207, thereby driving the gear 302 to start to rotate; one side of the rack 301 is provided with a gear 302, the gear 302 The two sides are meshed with the rack 301 and the moving block 304 respectively, the number of gears 302 is two, and the rotation of the gear 302 causes the moving block 304 to start moving upward;

[0042] The gear 302 is provided with a positioning block 303 , and one end of the positioning block 303 away from the gear 302 is fixedly connected to the outer frame 206 . The size of the positioning block 303 matches the distance between the gear 302 and the outer frame 206 , and the positioning block 303 defines the position of the gear 302 The gear 302 is provided with a moving block 304 on the side away from the rack 301, the moving block 304 is eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com