Closed stock ground

A stockyard and stockyard technology, which is applied in the field of bulk material storage and transportation facilities, can solve the problems of incomplete and effective connection, equipment damage, and insufficient excavation of the storage capacity of the transverse partition wall, so as to save civil engineering The effect of enhancing the quantity and structural mechanical performance and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

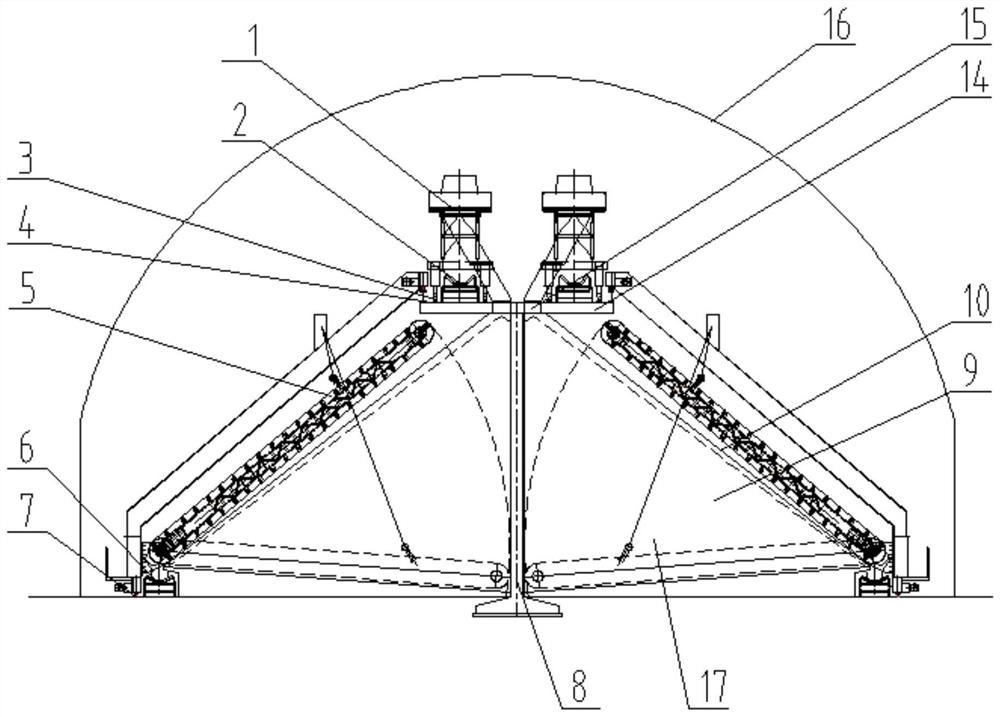

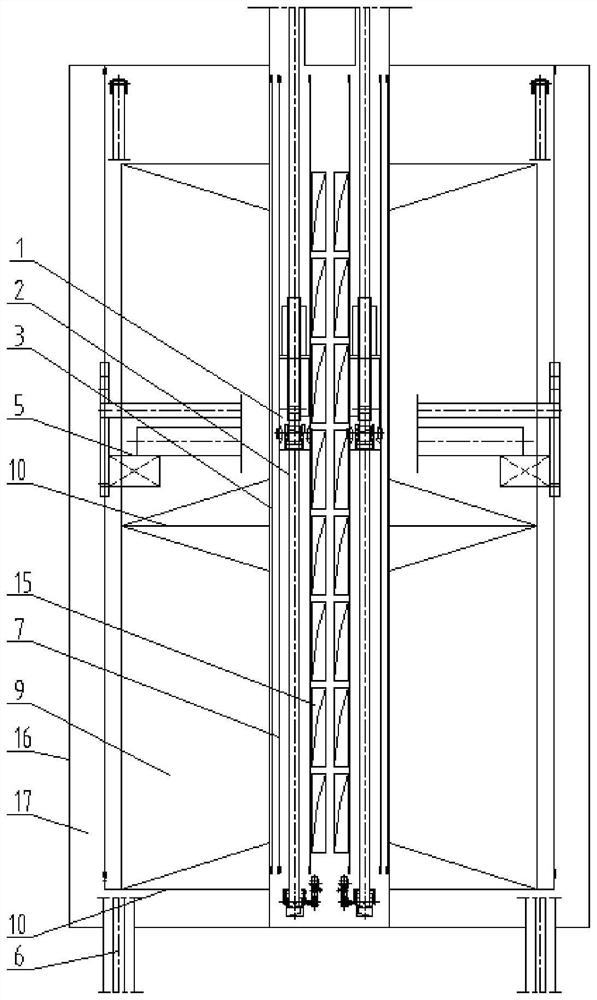

[0029] like figure 1 , figure 2 As shown in the figure, a closed material yard includes a stacking device 1, a reclaiming device 5, a running track 3 of the stacking device, an upper running track 4 of the reclaiming device, a lower running track 7 of the reclaiming device, a material input conveyor 2, and a material input conveyor 2. The output conveyor 6, the unloading platform 14, the storage yard 17, the closed storage shed 16, the inner side of the unloading platform 14 is provided with a plurality of first elongated holes 15 along its longitudinal direction, and the stacking device 1 is installed on the unloading platform 14. A blanking chute is arranged on the inner side of the stacking device 1, and the blanking chute discharges the material into the material yard 17 through the first elongated hole 15 provided on the inner side of the unloading platform 14.

[0030] In this embodiment, the bottom of the unloading platform 14 is connected with the top of the transver...

specific Embodiment 2

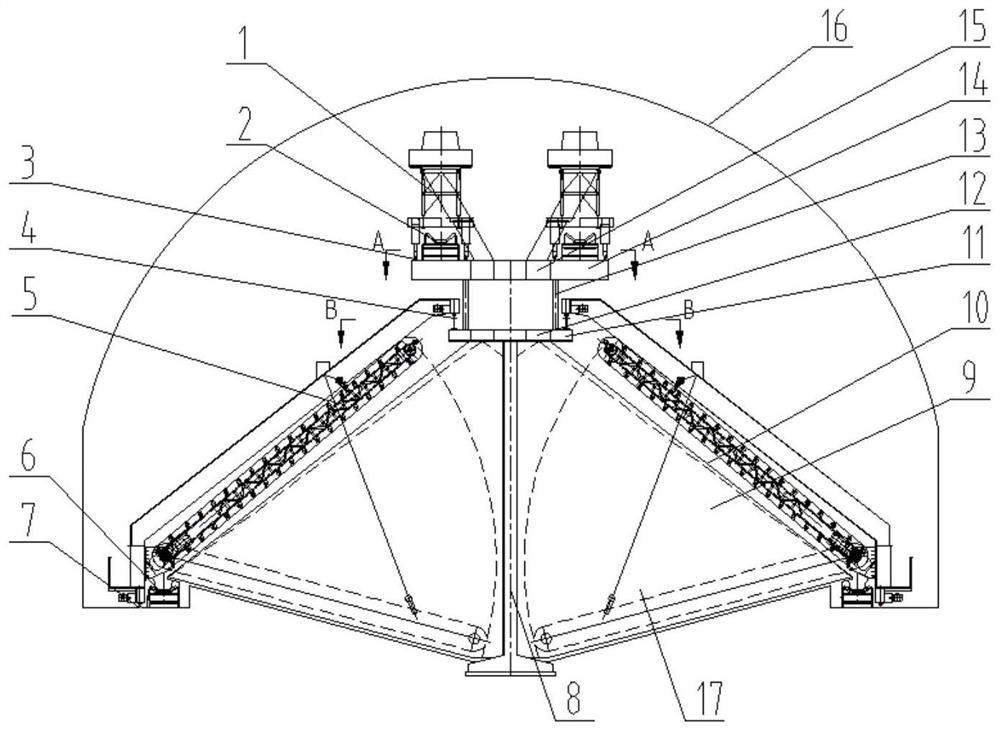

[0033] like Figure 3 to Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that a small T-shaped table 11 is also provided below the unloading platform 14, and the unloading platform 14 is supported by the upright column 13 arranged on the small T-shaped table. In this embodiment, the inner side of the small T-shaped platform 11 is provided with a plurality of second elongated holes 12 along its longitudinal direction, and the second elongated holes 12 correspond to the positions of the first elongated holes 15 of the discharge platform. The stacking device 1 of this embodiment is installed on the unloading platform 14 , and a blanking chute is arranged inside the stacking device 1 . The shaped hole 12 discharges the material into the pile 9 . The top unloading platform 14 in this embodiment is supported by double rows of uprights 13, and the stability of the unloading platform 14 is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com