Solvent-based cleaning agent, preparation thereof and method for cleaning organic heat carrier system by using solvent-based cleaning agent

A cleaning agent and solvent-based technology, which is applied in the cleaning of organic heat carrier systems, solvent-based cleaning agents and their preparation fields, can solve problems such as safety production accidents, pipeline rupture, and poor removal ability of solid oil dirt, so as to ensure safe operation and prolong Long service life and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

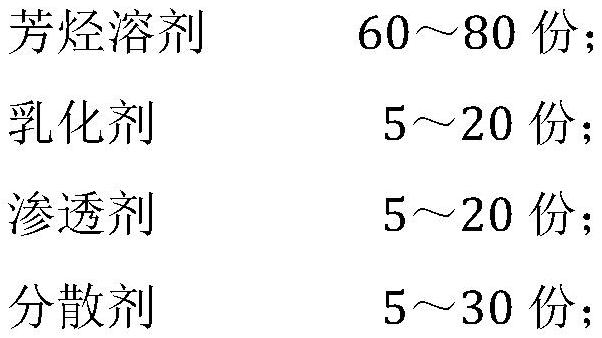

[0038] The solvent-based cleaning agent of the present invention comprises each component of the following parts by weight:

[0039]

[0040] Preparation: add C10 aromatic hydrocarbon solvent, tridecyl polyoxyethylene (6) ether, nonylphenol polyoxyethylene (10) ether, dodecylbenzenesulfonic acid isopropylamine into the preparation tank according to the proportioning , mixed thoroughly, heated to 55 ℃~60 ℃ and kept for 30 minutes, started ultrasonic wave to carry out peptization for at least 30 minutes, and then the solvent-based cleaning agent was obtained.

Embodiment 2

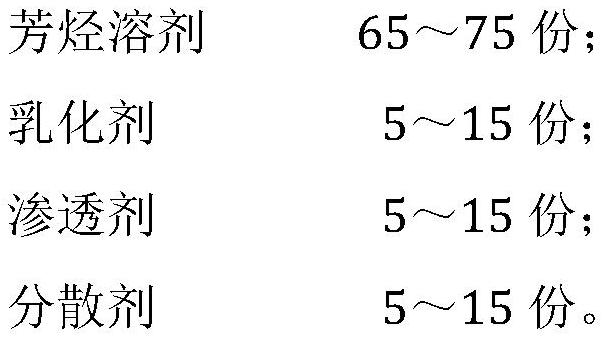

[0042] The solvent-based cleaning agent of the present invention comprises each component of the following parts by weight:

[0043]

[0044]

[0045] Preparation: add C10 aromatic hydrocarbon solvent, tridecyl polyoxyethylene (6) ether, nonylphenol polyoxyethylene (10) ether, dodecylbenzenesulfonic acid isopropylamine into the preparation tank according to the proportioning , mixed thoroughly, heated to 55 ℃~60 ℃ and kept for 30 minutes, started ultrasonic wave to carry out peptization for at least 30 minutes, and then the solvent-based cleaning agent was obtained.

Embodiment 3

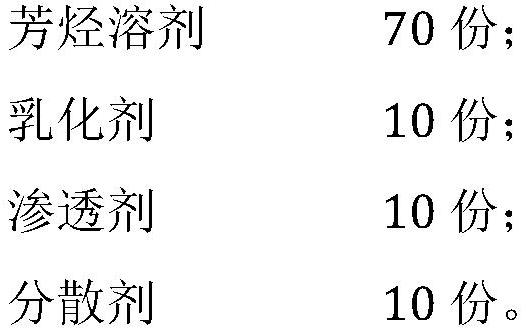

[0047] The solvent-based cleaning agent of the present invention comprises each component of the following parts by weight:

[0048]

[0049] Preparation: add C10 aromatic hydrocarbon solvent, tridecyl polyoxyethylene (6) ether, nonylphenol polyoxyethylene (10) ether, dodecylbenzenesulfonic acid isopropylamine into the preparation tank according to the proportioning , mixed thoroughly, heated to 55 ℃~60 ℃ and kept for 30 minutes, started ultrasonic wave to carry out peptization for at least 30 minutes, and then the solvent-based cleaning agent was obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap