Automatic desilting finished vehicle washing pool and construction method thereof

A construction method and technology for silting finished products, applied in the field of automatic dredging finished car wash pools and their construction, can solve the problems of complex and frequent processes, large material input, increased labor costs, etc., so as to reduce the construction period, reduce construction waste, The effect of reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The car wash tank body 1 is made of Q235 steel plate as a whole, with a thickness of 20-25mm.

[0035] At the same time, a construction method for an automatic dredging finished car wash pool is disclosed, comprising the following construction steps:

[0036] The implementation of embodiment 1 is:

Embodiment 2

On the basis of Example 1, increase:

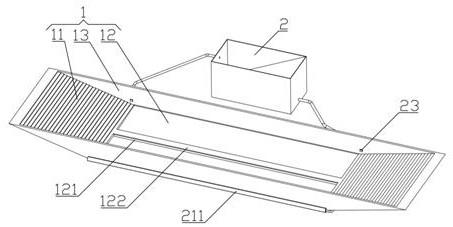

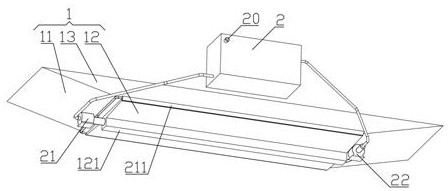

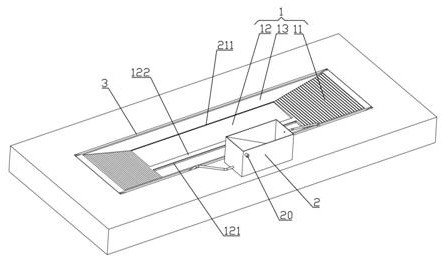

refer to Figure 1-3, the two sides of the bottom plate 12 are higher than the middle and inclined toward the middle, the two ends of the bottom plate 12 are connected with a slope plate 11, the slope plate 11 is inclined and the end away from the bottom plate 12 is higher than the bottom plate 12, the bottom plate 12 and the slope Vertical plates 13 are provided on both sides of the plate 11 .

[0038] refer to figure 1 and 3 The connection between the bottom plate 12 and the vertical plate 13 is provided with a waterfall water tank 211. The waterfall water tank 211 is connected with the sedimentation tank 2 through a pipeline.

[0039] refer to figure 1 and 3 , a baffle plate 122 is arranged directly above the sludge tank 121 , and a gap is formed between the two sides of the baffle plate 122 and the bottom plate 12 .

[0040] refer to Figure 1-3 , a filter plate 20 is inclined inside the sedimentation tank 2. The filter plate 20 ...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com