Integral disassembly, assembly and transportation method for lead of disassembled transformer

A transportation method and technology for transformers, applied in the direction of transformer/inductor coil/winding/connection, electronic waste recycling, recycling technology, etc., can solve the problems of cumbersome operation and low work efficiency, reduce wiring work and improve work efficiency Efficiency, the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

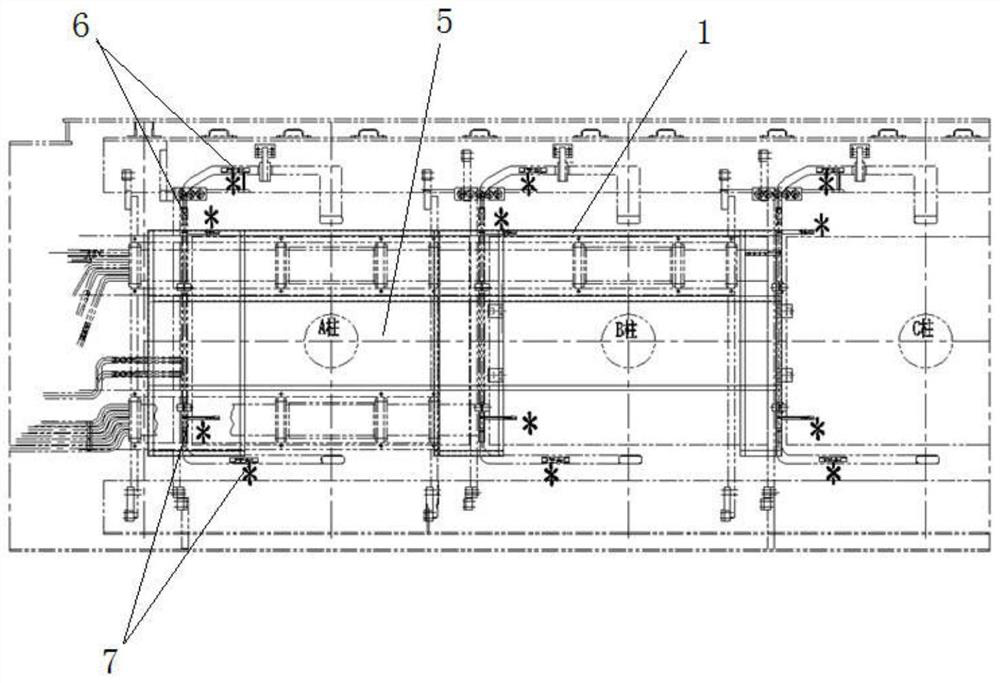

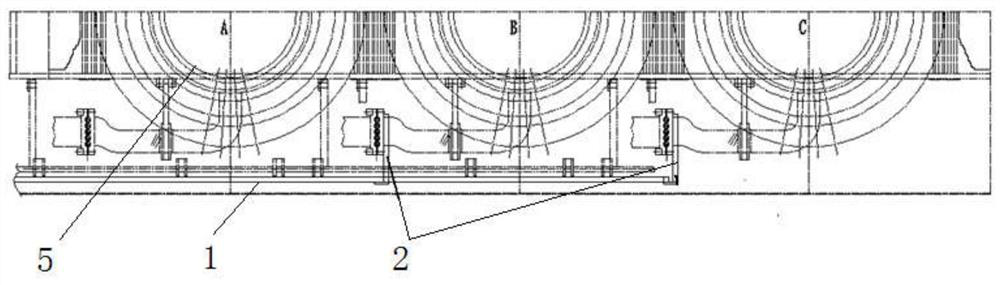

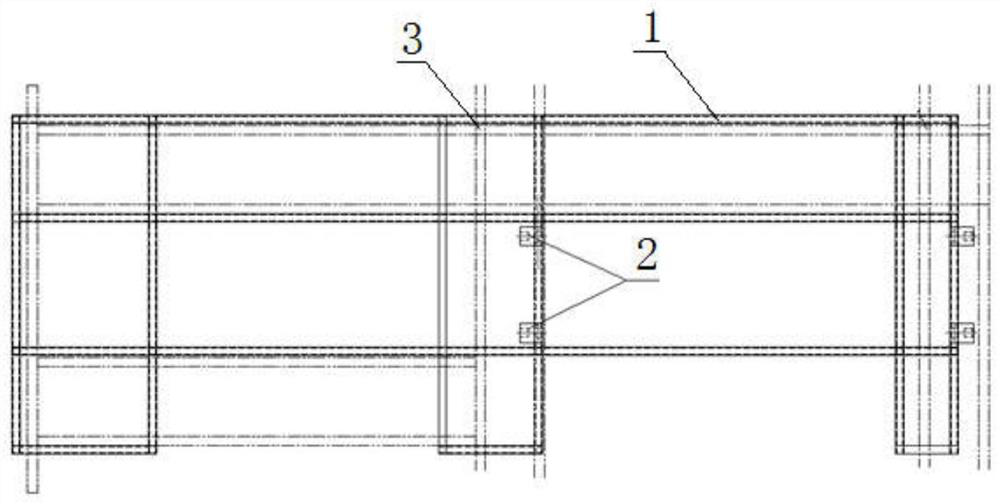

[0031] The present invention provides a method for disassembling, assembling and transporting the lead wires of a disassembled transformer. The method includes the dismantling and transporting of the lead wires and the on-site installation of the lead wires; wherein the disassembling and transporting the lead wires adopts an integral transportation mode, and the high-voltage lead wires, the voltage regulating leads and the insulating wood pieces are integrally fixed on the The lead wire is disassembled and assembled on the transportation bracket, and then fixed on the transportation cover plate together with the support pedestal by the lock, and then transported to the installation site together with the transformer body.

[0032] like Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com