Vehicle-mounted heating system for separating and melting thick ice layer

A heating system and ice layer technology, applied in the direction of heating elements, heating element shapes, ohmic resistance heating parts, etc., can solve the problem that vehicles lack the emergency performance of self-cleaning thick ice and snow layers, affect the service life of various parts of the car, affect the car paint and problems such as the integrity of the car surface, to achieve the effect of shortening the cleaning time, various deformation, and various forms of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

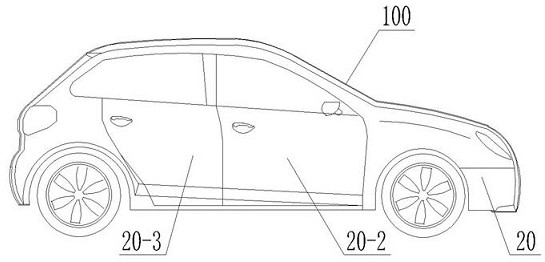

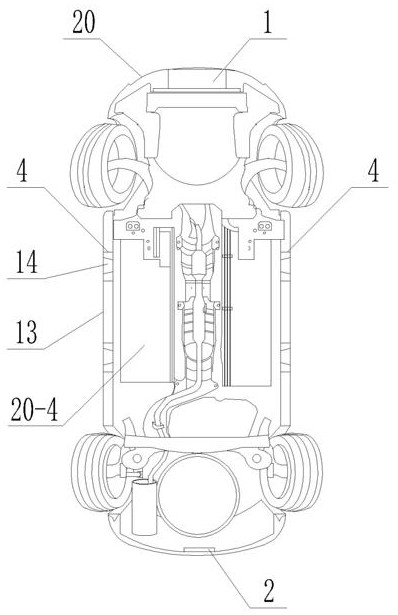

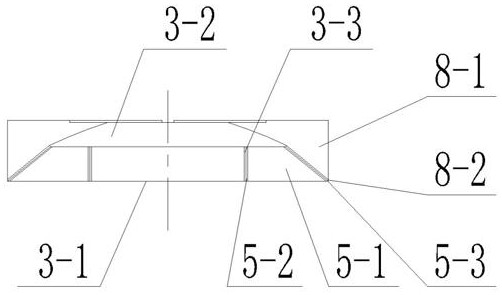

[0018] Embodiment 1: Combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 Illustrating this embodiment, this embodiment includes a heating belt body 100, the heating belt body 100 is a strip-shaped flexible flat belt body, one end of the heating belt body 100 is a power connection end, and the other end of the heating belt body 100 is a movable end , the power connection end of the heating belt body 100 is connected to the battery 20-1 of the vehicle body 20, the bottom surface of the heating belt body 100 is the heating surface, and the heating belt body 100 includes a main belt body 3, two first sub-belt bodies 5 and Two second sub-belt bodies 8, one end of the main belt body 3 is arranged at the bottom of the front end of the vehicle body 20, the other end of the main belt body 3 is d...

specific Embodiment approach 2

[0021] Specific embodiment 2: This embodiment is a further limitation of specific embodiment 1, and also includes positioning and mounting parts. The positioning and mounting parts include a front total placing box 1, a rear connecting seat 2 and two separate placing frames 4. The front total placing box 1 It is arranged at the bottom of the front end of the vehicle body 20, the rear connecting seat 2 is arranged at the bottom of the rear end of the vehicle body 20, the two sub-placement frames 4 are respectively arranged at the bottom of both sides of the vehicle body 20, and the power connection end of the main belt body 3 is arranged at the bottom of the vehicle body 20. In the total placement box 1, the other end of the main belt body 3 is the moving end, the moving end of the main belt body 3 is detachably connected to the rear connecting seat 2 after passing through the top of the vehicle body 20, and one end of each first sub-belt body 5 is connected to the rear connectin...

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. In this embodiment, when both ends of the heating belt body 100 are respectively connected to the front and rear of the vehicle body 20, the outer wall of the vehicle body 20 The second zone is formed by heating the isolation of the belt body 100 .

[0038] like Figure 16 As shown, when the number of side connecting seats 4-3 on each side of the vehicle body 20 is one, one side connecting seat 4-3 cooperates with the first sub-belt body 5 to realize the ice covering the outside of the vehicle body 20. Layers are divided into four zones in the form of melting ice.

[0039] like Figure 17 As shown, when the number of the side connecting seats 4-3 on each side of the vehicle body 20 is two, the two side connecting seats 4-3 are arranged on the elongated frame body 4-1 side by side, and the two side connecting seats 4-3 are connected side by side. The seats 4 - 3 cooperate with the first sub-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com