Denture steam wax washing machine

A technology of wax washing machine and steam, which is applied in the direction of liquid cleaning method, climate sustainability, cleaning method and utensils, etc. It can solve the problems of low cleaning efficiency, failure to clean dentures, and inability to spray concentrated steam on dentures, etc. To achieve the effect of improving cleanliness, no temperature drop, and high wax washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

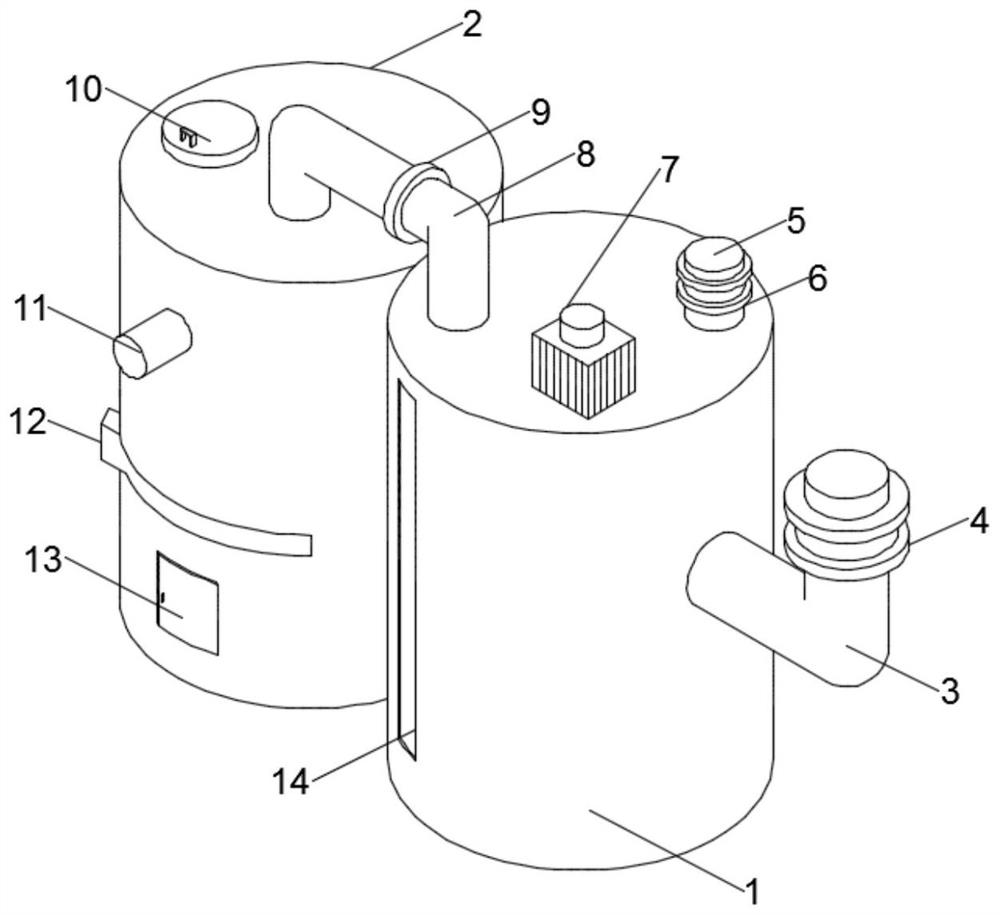

[0033] see Figure 1-6 As shown, the present invention is a denture steam wax washing machine, comprising a wax washing machine 2, a steam spray device arranged at the top of the wax washing machine 2, and a bearing device arranged at the bottom end of the steam spray device;

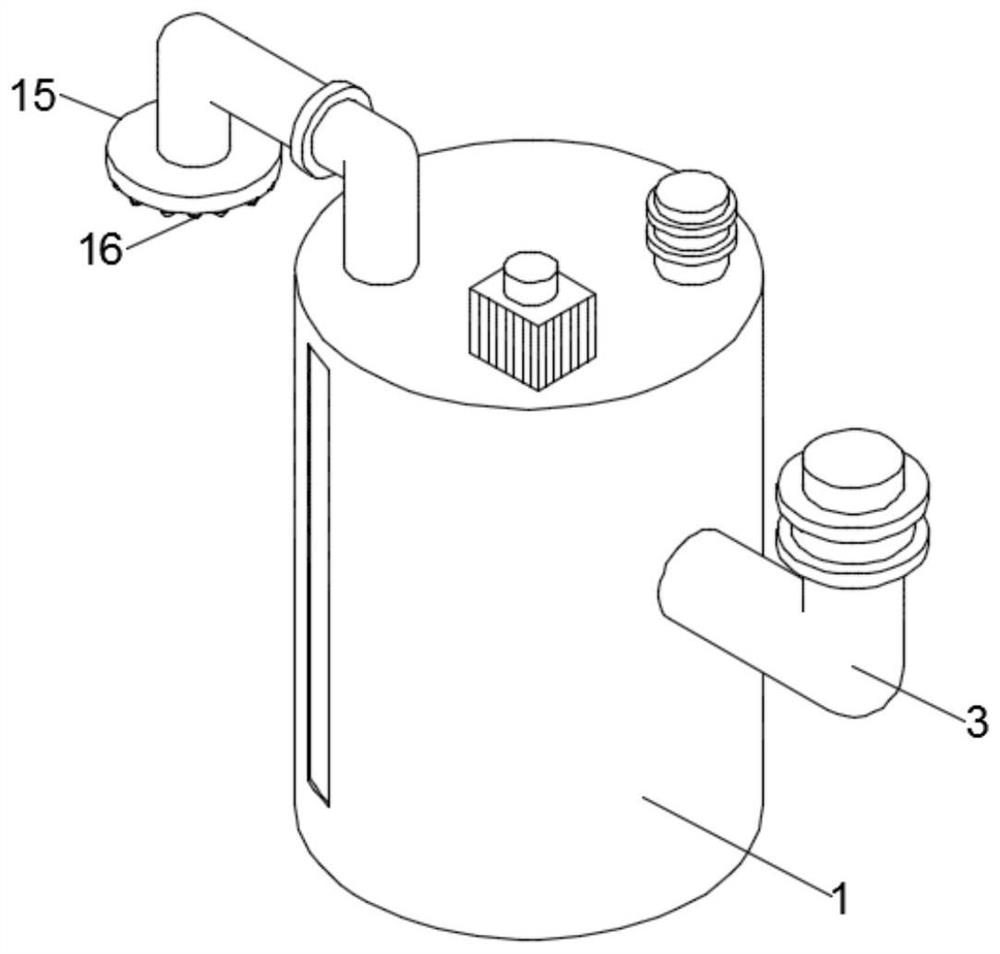

[0034]The steam injection device includes a steam backflow prevention pipe 8, a steam pan 15 and a steam injection head 16. The top of the wax washer 2 is provided with a through hole. The outer surface of the steam backflow prevention pipe 8 is fixedly connected to the inner wall of the through hole. The steam backflow prevention pipe 8 The outer surface of the steam pan 15 is wrapped with a layer of thermal insulation cotton, the top end of the steam pan 15 is fixedly connected with the bottom end of the anti-steam backflow pipe 8, and the steam jet head 16 is fixedly arranged at the bottom end of the steam pan 15; The steam reaches the steam pan 15 through the anti-steam backflow pipe 8, and the stea...

Embodiment 2

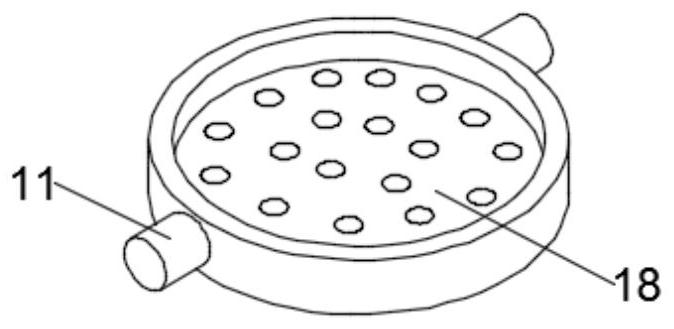

[0046] see Figure 1-6 As shown, the present invention is a denture steam wax washing machine, and its use method and working principle are as follows: first, open the cover 10, put the denture on the rubber plate 18, start the battery 7, and make the battery 7 supply the heating rod 22. And the heating wire 20 is powered, the heating rod 22 makes the water in the steam cylinder 1 be heated into steam, and then the third solenoid valve 9 is opened, so that the steam flows from the inlet of the anti-steam backflow pipe 8 into the steam tray 15, if the steam flow When it is too small to flush the red wax on the denture, start the air pump 17 to make the steam flow larger, and then the steam is sprayed from the steam jet head 16 to the denture. At this time, the electromagnetic vibrator is activated to make the denture turn over, because the rubber plate 18 is soft. Therefore, the dentures will not be damaged. The steam after rinsing the dentures becomes waste water. The washed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com