Heat-sealing three-dimensional bag intermediate product and application of heat-sealing three-dimensional bag intermediate product in manufacturing of heat-sealing three-dimensional bag

A three-dimensional bag and product technology, applied in the manufacture of flexible containers, bags, sacks, etc., can solve the problems of inability to manufacture packaging bags, inability to use, difficult to print, etc., and achieve the effect of saving plate-making costs and shortening the manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

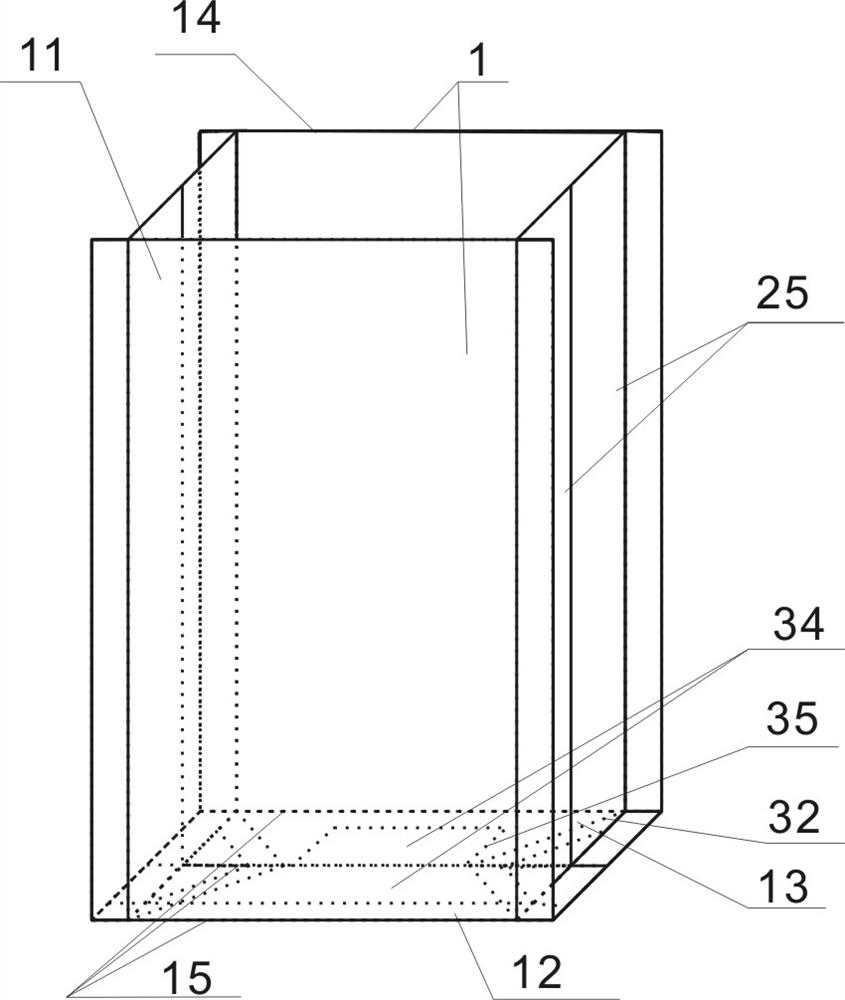

[0069] Embodiment 1: a kind of Figure 1~Figure 4 Shown heat-sealed three-dimensional bag intermediate product and its application in the manufacture of heat-sealed three-dimensional bag

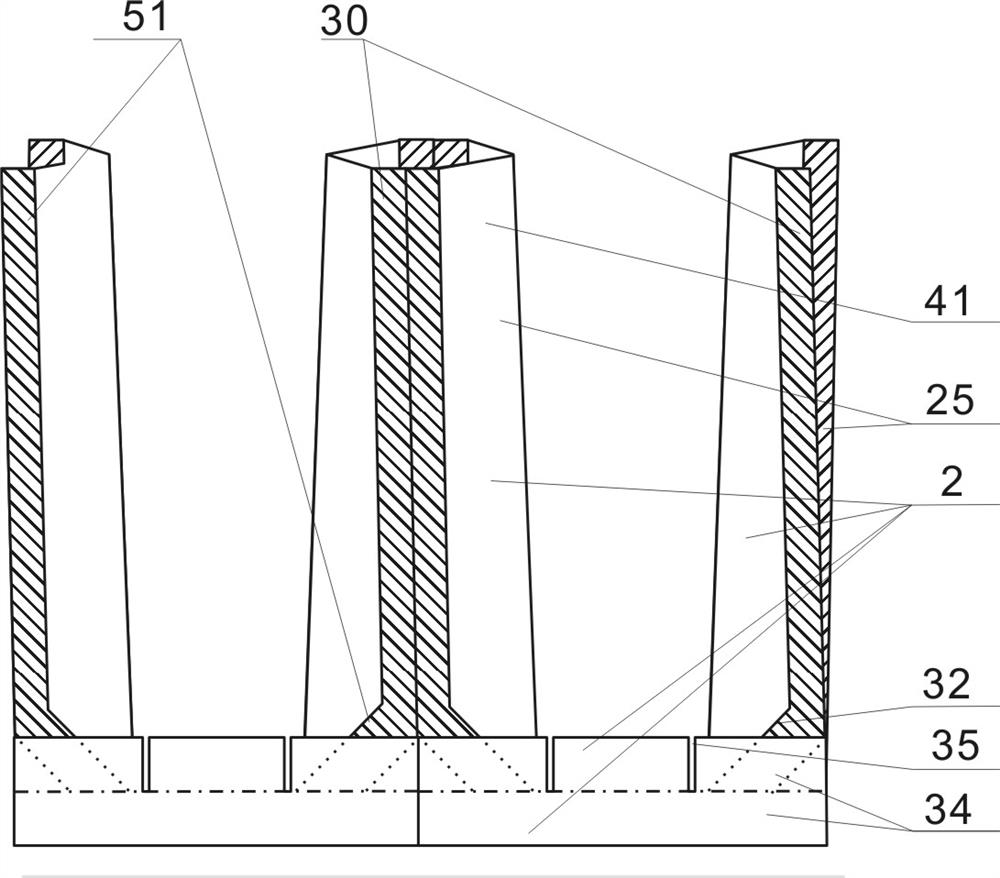

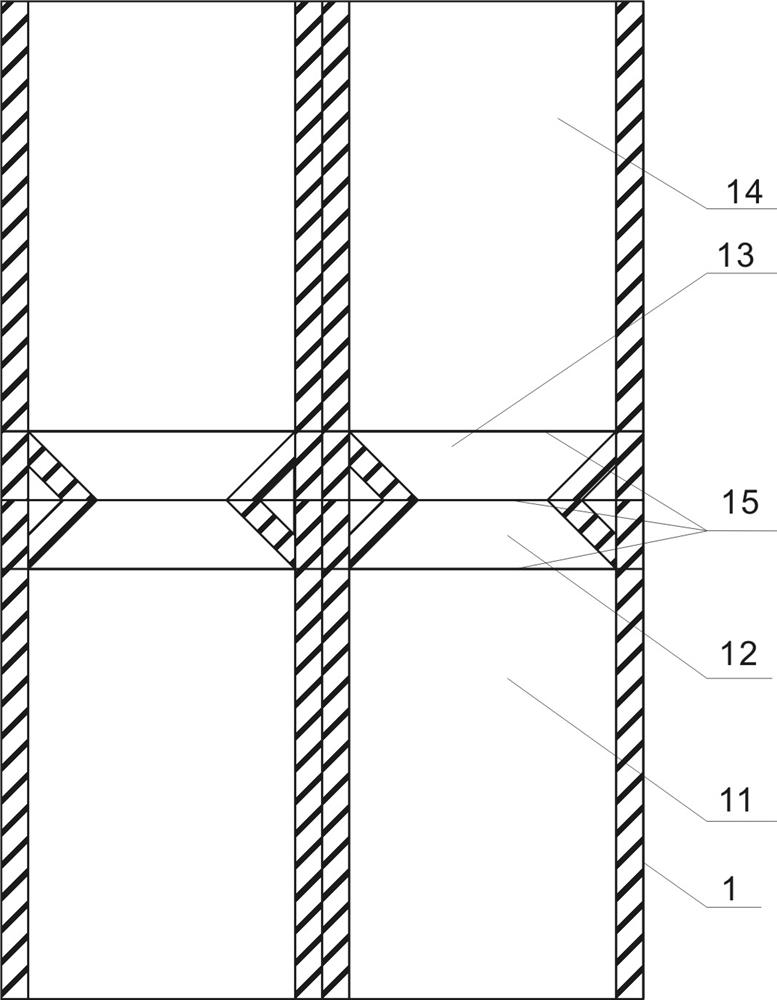

[0070] The intermediate product of the heat-sealed three-dimensional bag is a main sticky bag body used for thermal bonding with the main sticky printing fabric to be adhered to quickly produce a three-dimensional bag. Stick the main bag body 2 such as figure 2 The main bag body 2 of the conjoined body to be adhered includes the folded side material of the bag body, and the folded side material of the bag body is the longitudinal inner folded side material 25 of the bag body without printing graphic information before molding.

[0071] The conjoined main bag body 2 is provided with an outer heat-sealing and adhesive surface, and the outer heat-sealing and adhesive surface is provided with a local heat-bonding area. The necessary heat-sealing edges 51 include longitudinal heat-sealing edge...

Embodiment 2

[0082] Embodiment 2: a kind such as Figure 5~Figure 7 Shown heat-sealed three-dimensional bag intermediate product and its application in the manufacture of heat-sealed three-dimensional bag

[0083] Compared with the first embodiment, the differences are as follows:

[0084] The conjoined main bag body 2 to be adhered includes the front material 21 of the bag body, the outer side folded bottom side material of the bag, and the back material 24 of the bag body, which is composed of the outer side material 22 of the front half of the bag and the side material 23 of the outer side folded of the latter half of the bag. And the folded side panel 25 inside the longitudinal bag. The inner surface of the conjoined main bag body 2 is a high temperature retort-resistant film surface with high temperature heat sealing temperature of 200°. Retort grade unstretched polypropylene (RCPP) can be selected. The conjoined main bag body 2 is adhered to. The outer heat-sealed and adhered surfa...

Embodiment 3

[0089] Embodiment three: a kind such as Figure 8 Shown heat-sealed three-dimensional bag intermediate product and its application in the manufacture of heat-sealed three-dimensional bag

[0090] Compared with the first embodiment, the differences are as follows:

[0091] The intermediate product of the heat-sealed three-dimensional bag is the main bag body 2 of the conjoined body of four self-supporting bag bodies with burrs. The folded bottom side material 26 of the bag body is thermally bonded and fixed to the front material 21 of the bag body and the back material 24 of the bag body according to the structure of a stand-up bag with a convex-concave self-sealing buckle 36 . The main bag body 2 of the conjoined body to be adhered includes a convex and concave self-sealing buckle 36, the front fabric 21 of the bag body, the back fabric 24 of the bag body, and the folded bottom side material 26 of the bag body. The inner layer of the main bag body 2 is a high temperature RCPP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com