Node connecting device of hydraulic prefabricated assembly type concrete member

A technology of prefabricated assembly and node connection, which is applied in building construction, processing of building materials, construction, etc., can solve the problem of insufficient stability and adaptability, insufficient accuracy of installation and positioning of prefabricated concrete components, and reduced building stability and Efficiency and other issues to achieve the effect of improving accuracy and stability, improving adaptability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

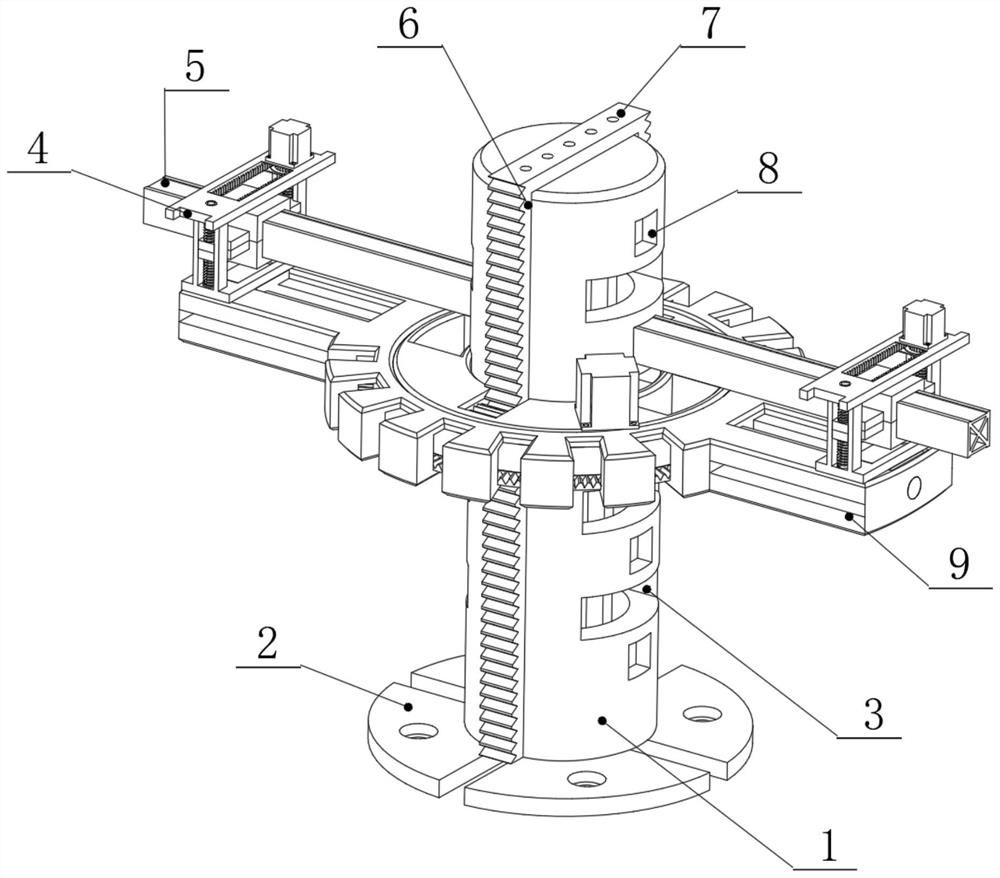

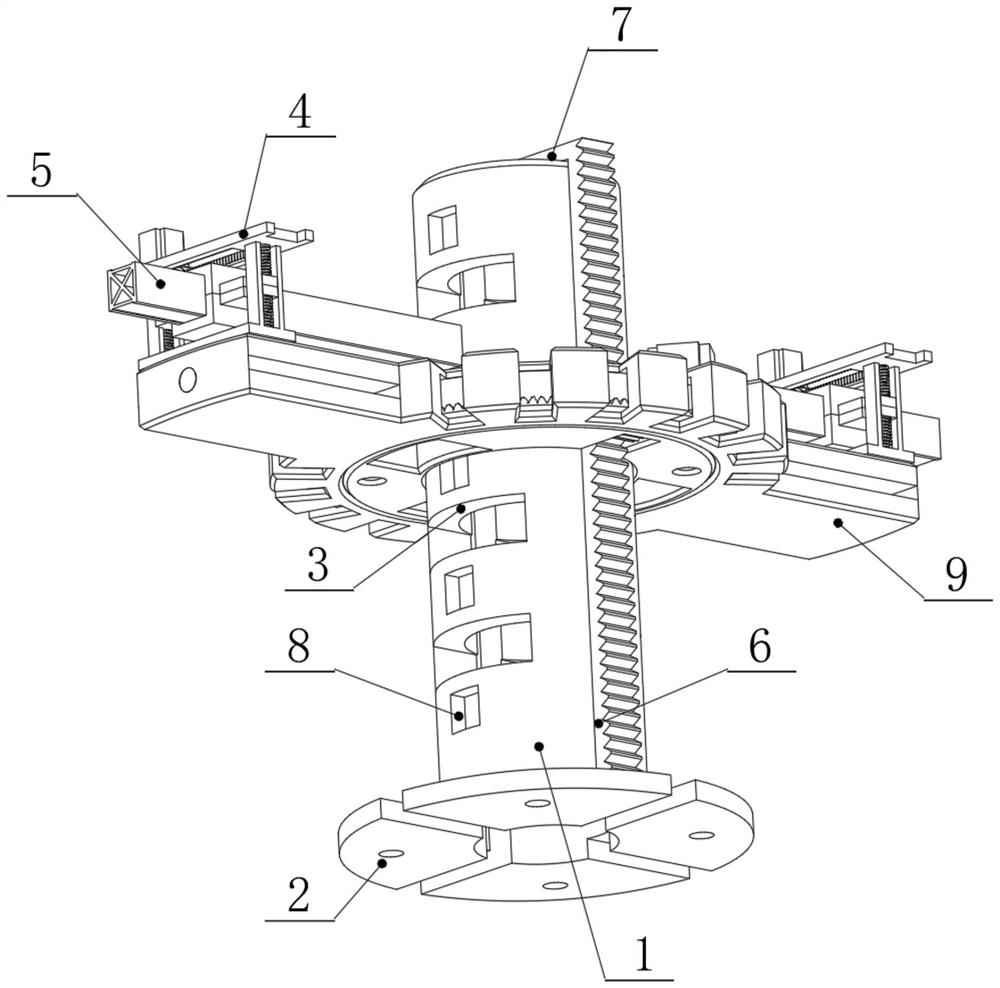

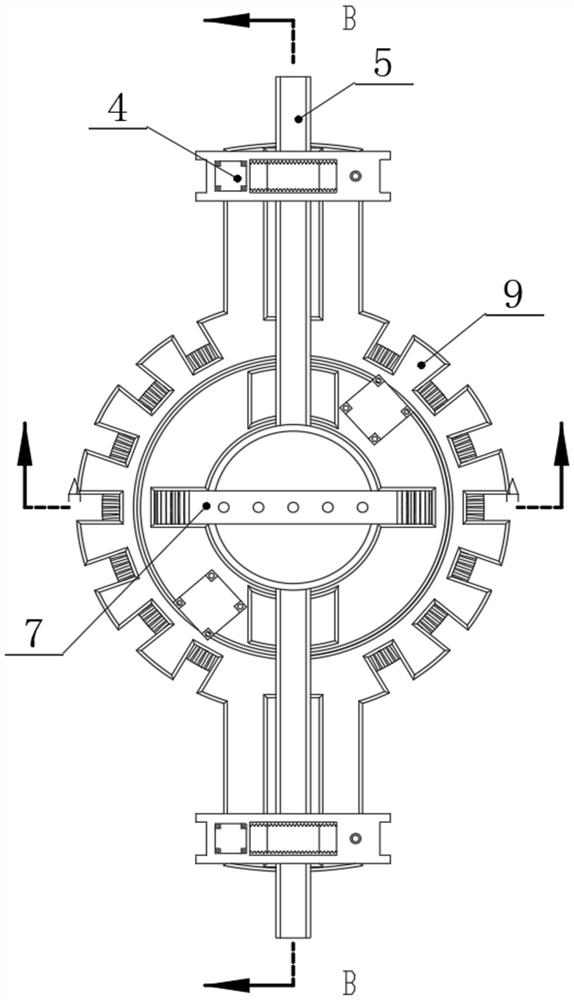

[0050] see figure 1 , figure 2 , image 3 , Image 6 , Figure 7 and Figure 8 As shown in the figure, an embodiment provided by the present invention: a node connection device for hydraulic prefabricated concrete components, including a concrete pillar 1, a connection card plate 2, a fixed guide hole 3, a limiting device 4, and a concrete prefab 5 , connecting rack 6, support guide plate 7, positioning slot 8 and guide device 9;

[0051] Four groups of connection clips 2 are fixedly installed on the lower end face of the concrete pillar 1 evenly and equidistantly;

[0052] A fixed guide hole 3 is opened between the adjacent positioning slots 8, a support guide plate 7 is fixedly clamped at the center of the upper end surface of the concrete pillar 1, and a connecting rack 6 is symmetrically and fixedly installed on the side end surface of the support guide plate 7;

[0053] The inner end surface of the guide device 9 is meshed and connected to the outer end surface of ...

Embodiment 2

[0074] On the basis of Example 1, as Figure 10 As shown, the clamping plate 43 includes a connecting screw hole 431, a spring plate 432, a positioning support plate 433 and a connecting side plate 434. The side end of the positioning support plate 433 is symmetrically and fixedly installed with the connecting side plate 434, and is located on the connecting side plate. The end of the 434 is provided with a connection screw hole 431, and the lower end of the positioning support plate 433 is symmetrically fixed with a spring clip 432.

[0075]In the implementation of this embodiment, the two sets of spring clips 432 can be stably limited to the upper part of the concrete prefab 5, thereby maximizing the stability of the position limitation of the concrete prefab 5, and at the same time connecting the threaded holes 431 and the bidirectional wire The cooperation of the rods 46 can effectively improve the stability of the support connection to the prefabricated concrete 5 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com