Gas inlet device meeting requirements of pneumatic conveying industry for conveying clean gas

A technology of clean gas and pneumatic conveying, which is applied to the components of pumping devices for elastic fluids, human health protection, climate sustainability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

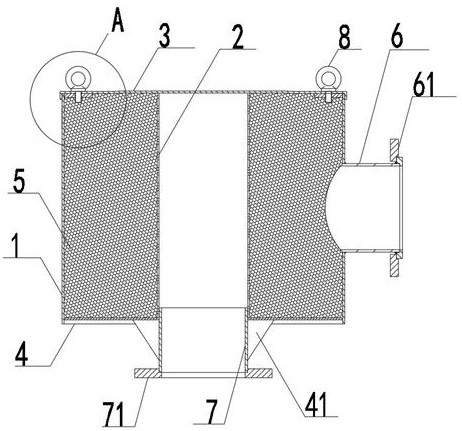

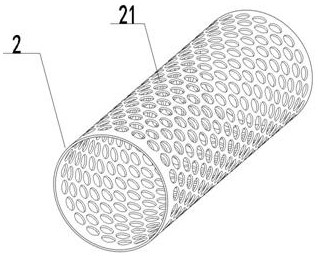

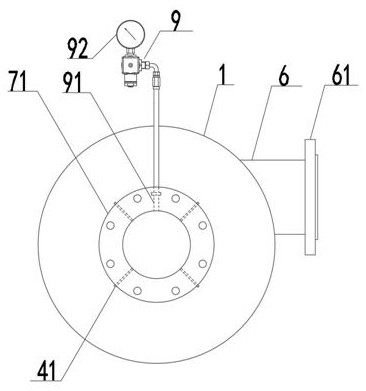

[0038] Attached below Figure 1-7 To further illustrate the present invention, an air intake device that satisfies the requirements of the pneumatic conveying industry to convey clean gas, such as figure 1 and 2 As shown, it includes an outer cylinder 1, an inner cylinder 2, a top cover 3 and a bottom plate 4; the top end of the outer cylinder 1 is sealed and fixedly connected to the top cover 3; the bottom end of the outer cylinder 1 is sealed and fixed to the bottom plate 11 ; The inner cylinder 2 is arranged inside the outer cylinder 1, the top end of the inner cylinder 2 is against the position of the top cover 3, and the bottom end passes through the bottom plate 4 of the outer cylinder 1 and communicates with the outside; in the outer cylinder 1 , The space enclosed by the inner cylinder 2, the top cover 3 and the bottom plate 4 is also filled with filter filler 5; the outer cylinder 1 is connected with an air inlet pipe 6 through the cylinder wall; the inner cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com