Photovoltaic module and preparation method thereof

A photovoltaic module and packaging film technology, applied in the field of solar energy, can solve problems such as increased labor intensity, poor stability of solar photovoltaic modules, and inability to position solar cells or battery strings, so as to improve stability and service life and avoid relative movement , Improve the effect of yield and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

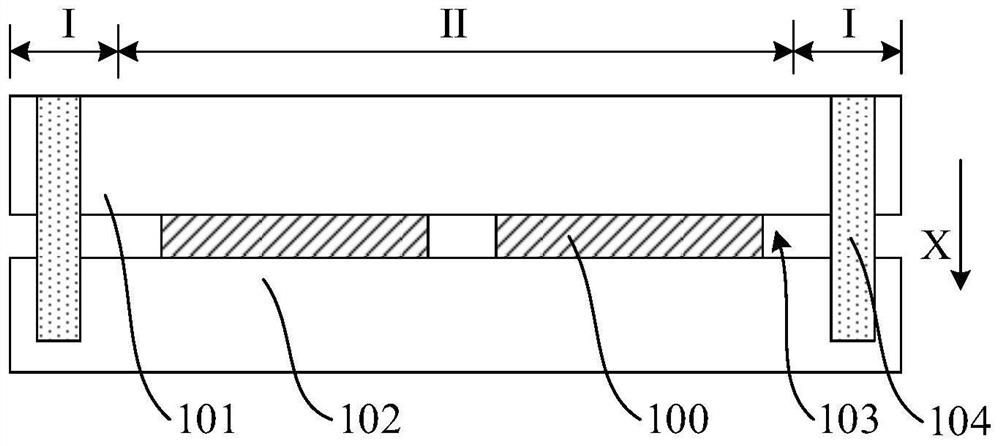

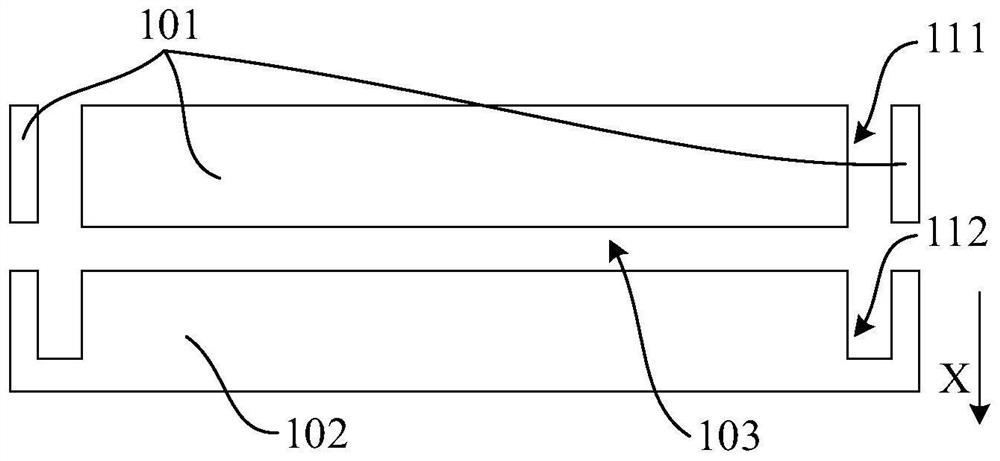

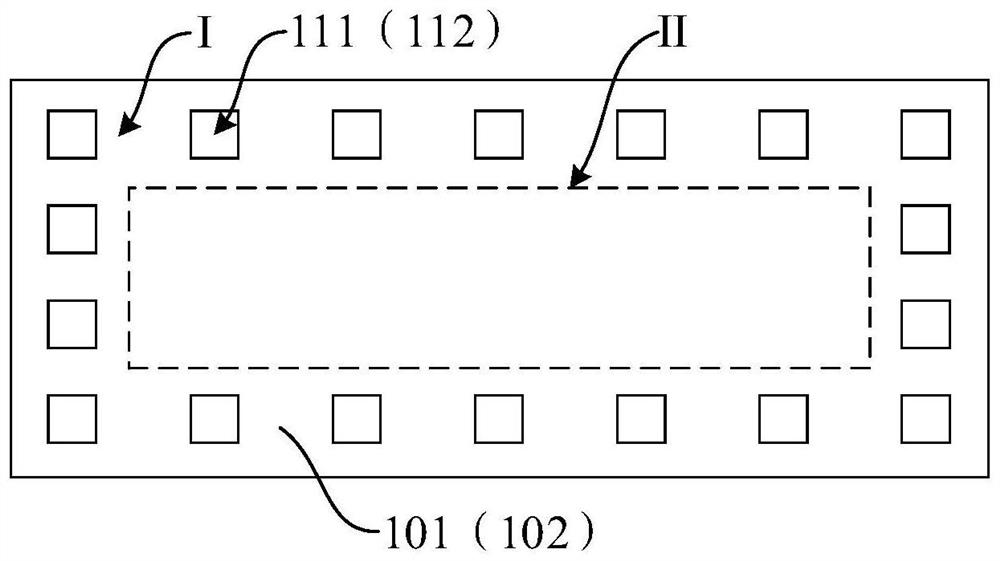

[0072] refer to Figure 13 to Figure 19 , the preparation method of the photovoltaic module includes: providing a battery string 100; forming the first encapsulating adhesive film 101 provided in the foregoing embodiment, the first encapsulating adhesive film 101 is located on one side of the battery string 100; forming the second encapsulating adhesive provided in the foregoing embodiment. The film 102 and the second packaging film 102 are located on the side of the battery string 100 away from the first packaging film 101, wherein the first packaging film 101 in the peripheral area I has a first through hole 111, and the second packaging film in the peripheral area I has a first through hole 111. The adhesive film 102 has a second through hole 112 .

[0073] It should be noted, Figure 14 for Figure 13 Provided is a schematic cross-sectional structure diagram of the first encapsulation film 101 of the photovoltaic module, Figure 15 for Figure 13 A schematic cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com