Large-tonnage guy cable hanging basket sliding rail mounting and connecting mechanism and method

A connection mechanism, large tonnage technology, applied in building structure, house structure support, house structure support and other directions, to achieve the effect of improving convenience, sliding safety and stability, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] S3: Adaptation and adjustment with hanging baskets of different specifications:

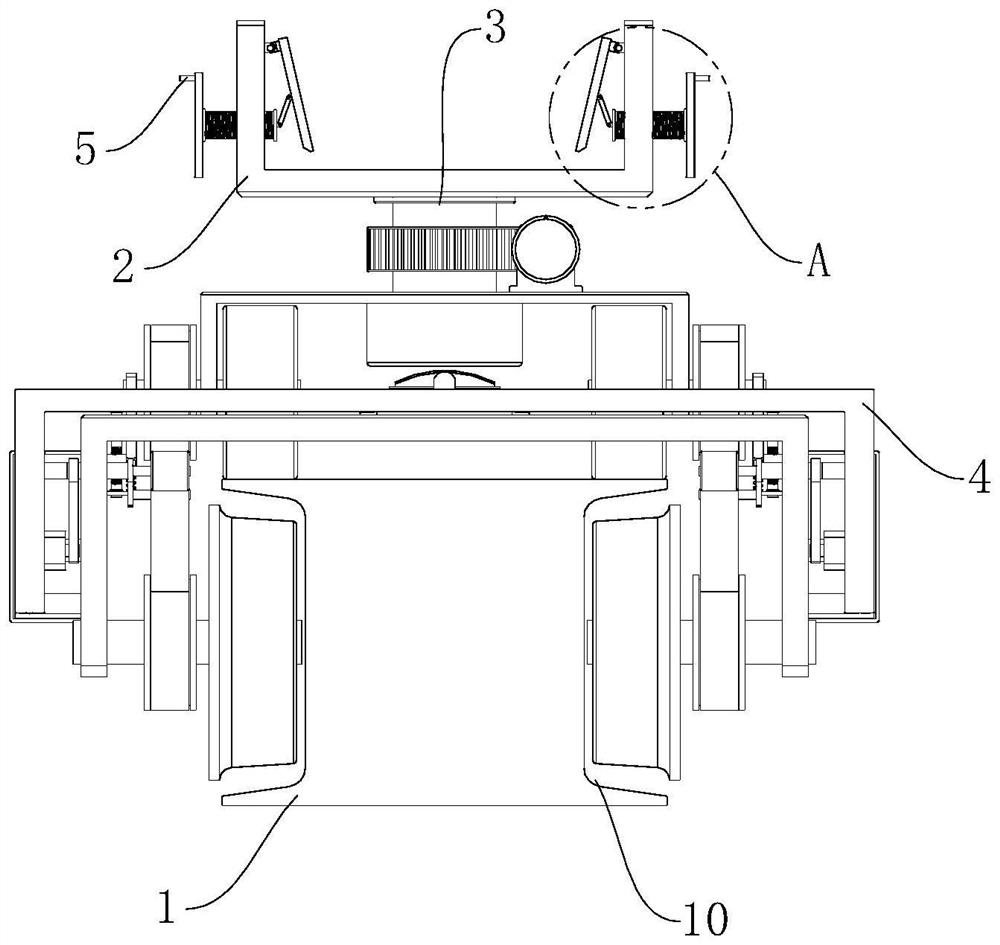

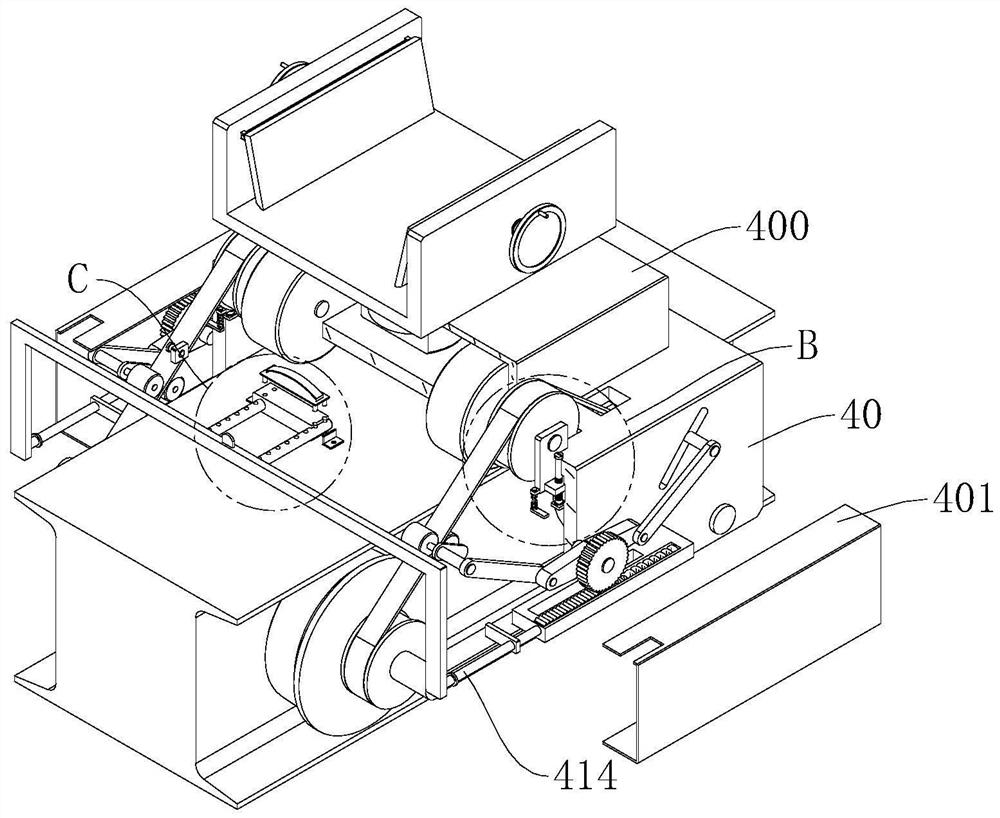

[0044] The working principle of the present invention: this connection mechanism is only suitable for single-sided construction hanging baskets, and two sets are needed to realize the installation and connection of large-tonnage dragline hanging baskets and track 1, that is, two U-shaped brackets 2 are required to be respectively clamped on the At both ends of the bottom of the hanging basket, two groups of the mechanism are connected to the track 1 through eight pulleys 421 and four reverse pulleys 420 on the two sliding frames 40, and then the sliding frame 40 is pushed by a jack to realize Swipe function.

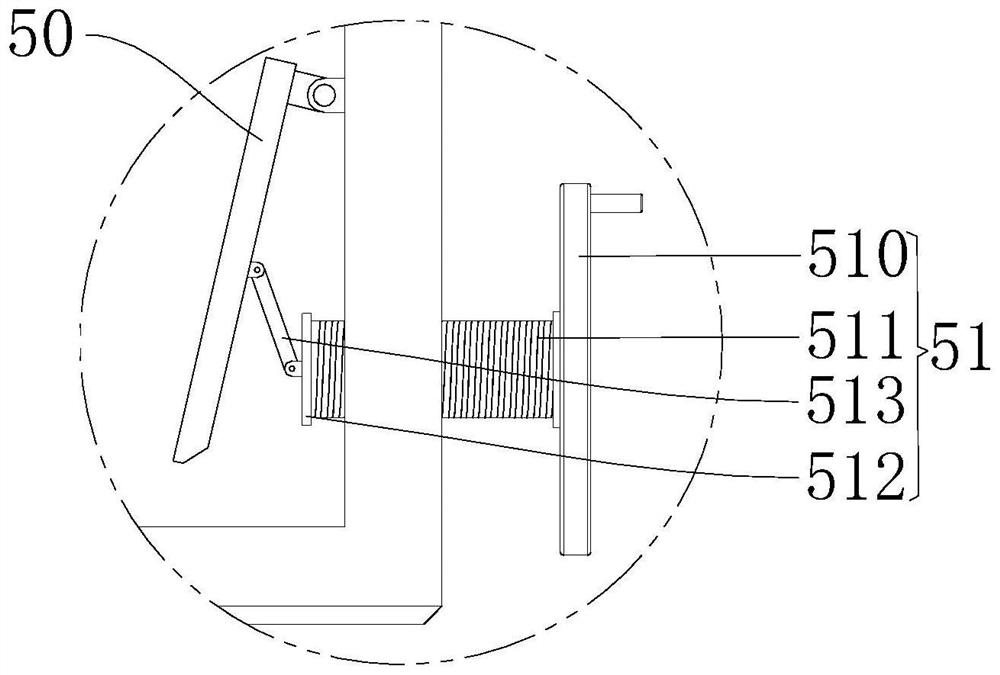

[0045] When installing, just push the buckle wheel 420 and the two pulleys 421 respectively to the track 1 along the upper edge of the track 1, and keep the buckle wheel 420 at the top of the upper edge of the track 1, and the two pulleys 421 on the track 1 along the bottom, so that...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com