Variable displacement motor, air conditioner compressor hydraulic driving system and control method

A technology of air-conditioning compressors and variable motors, which is applied in fluid pressure actuation system testing, servo motors, machines/engines, etc., to achieve the effects of improving stability, reducing energy loss, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

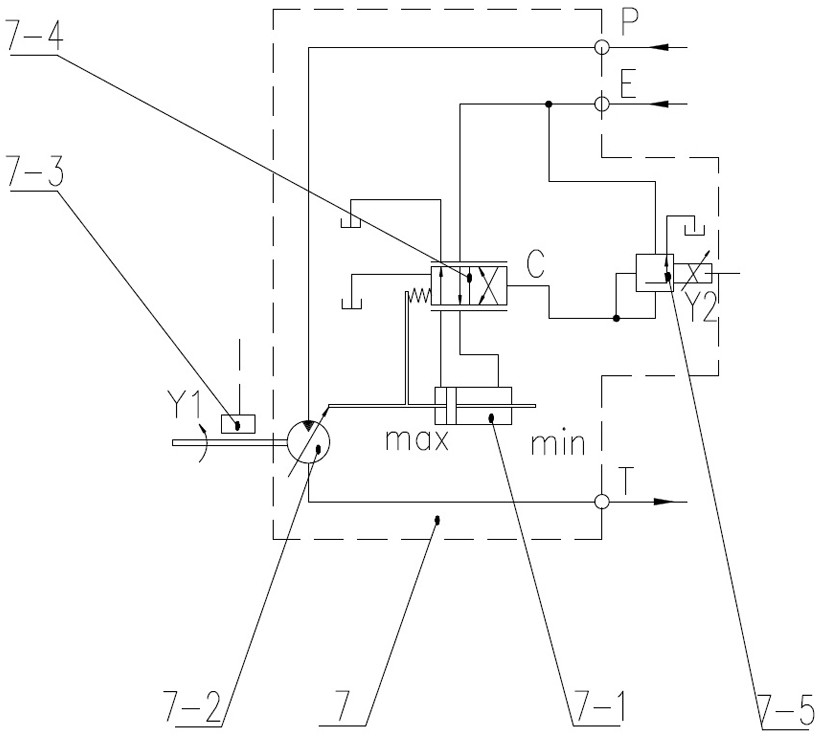

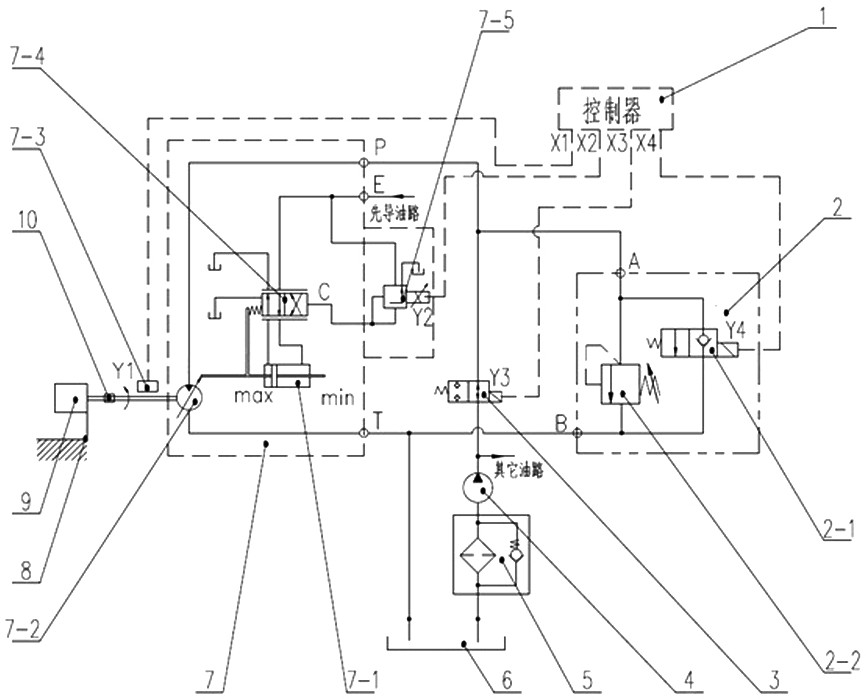

Embodiment Construction

[0028] Furthermore, in order to connect the hydraulic control system of the air conditioner compressor to the general hydraulic system of the excavator, a two-position two-way electromagnetic reversing valve I3 is also provided. Between the A port of the hydraulic pump 4, the point X3 of the controller 1 is connected with the point Y3 of the electromagnetic control end of the two-position two-way electromagnetic reversing valve I3. The two-position two-way electromagnetic reversing valve I3 controls the on-off of hydraulic oil flowing into the hydraulic control system of the air-conditioning compressor, so that the hydraulic control system of the air-conditioning compressor can be controlled independently.

[0029] Using the control method of the air conditioner compressor hydraulic drive system in the second embodiment above,

[0030] The set speed of the air conditioner compressor is a range, for example: 1500~3000r / min; the set speed of the air conditioner compressor is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com