Wellhead Christmas tree equipment sealing groove measuring and calibrating device and method

A technology of proofreading devices and measuring devices, which is applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., to achieve the effects of easy operation, reduced weight and easy portability

Inactive Publication Date: 2022-06-10

DEZHOU UNITED GASOLINEEUM MACHINERY

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to provide a wellhead Christmas tree equipment sealing groove measurement and calibration device and method, which are used to solve the problem of precision inspection of the sealing groove on the pressure vessel due to The large size of the sealing groove leads to the need to process a large number of calibration discs, and the problem that more calibration discs are inconvenient to carry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

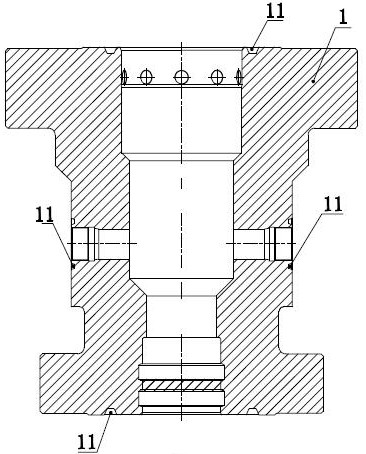

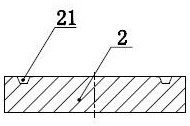

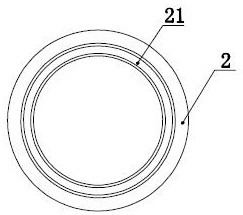

Login to View More Abstract

The invention discloses a wellhead Christmas tree equipment sealing groove measuring and calibrating device and method, relates to the technical field of detection devices, and is used for solving the problems that a large number of calibrating discs need to be processed due to the large size of the sealing groove and the large number of calibrating discs are inconvenient to carry when the precision of the sealing groove on a pressure container is tested. Comprising a measuring arm, the outer wall of the measuring arm is provided with a plurality of groups of calibration straight grooves, two calibration straight grooves arranged in a group are arranged in parallel, the cross section sizes of the calibration straight grooves in different groups or / and the distances between the calibration straight grooves are different, and one group of calibration straight grooves corresponds to sealing grooves of one specification. According to the invention, a plurality of groups of calibration straight grooves are arranged on the measuring arm, so that the requirements of testing sealing grooves with different sizes can be met; compared with a mode of arranging a group of calibration ring grooves on each calibration disc in the prior art, the weight of the calibration device is greatly reduced, the precision is high, the calibration device is basically free of abrasion, and the calibration device is convenient to carry and store; and compared with checking by using a checking ring groove, observation and comparison are easier.

Description

technical field [0001] The invention relates to the technical field of detection devices, in particular to a device and method for measuring and correcting sealing grooves of wellhead Christmas tree equipment. Background technique [0002] In recent years, although my country's offshore oil and gas drilling and completion equipment industry has achieved some achievements through technology introduction, cooperation, digestion, absorption, re-innovation and localization, compared with developed countries and leading enterprises in the industry with nearly a century of development history There is still a large gap. In various pressure vessel equipment such as petroleum or chemical industry, valves, pipe joints or pipe fittings are common parts, and the joints between valves and pipe fittings, as well as the joints of pipe joints, should ensure tightness. For example, between the Christmas tree and the pipeline, the seal between the two connected parts can be realized by addin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B5/00

CPCG01B5/00G01B5/0002

Inventor 何振瑜张桂昌孙玉全曹云志白广辽庞志国薛帅崔爱贞潘兵兵薛庆华

Owner DEZHOU UNITED GASOLINEEUM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com