Grinding and polishing erosion reagent for pearlite, and rapid metallographic examination method for pearlitic steel

A pearlitic steel and metallographic inspection technology, which is applied in the preparation of test samples, material analysis through optical means, and instruments, can solve the problems of difficult on-site operation, poor working conditions of metallographic inspection, and high risk. Achieve the effects of simple operation, high inspection efficiency and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

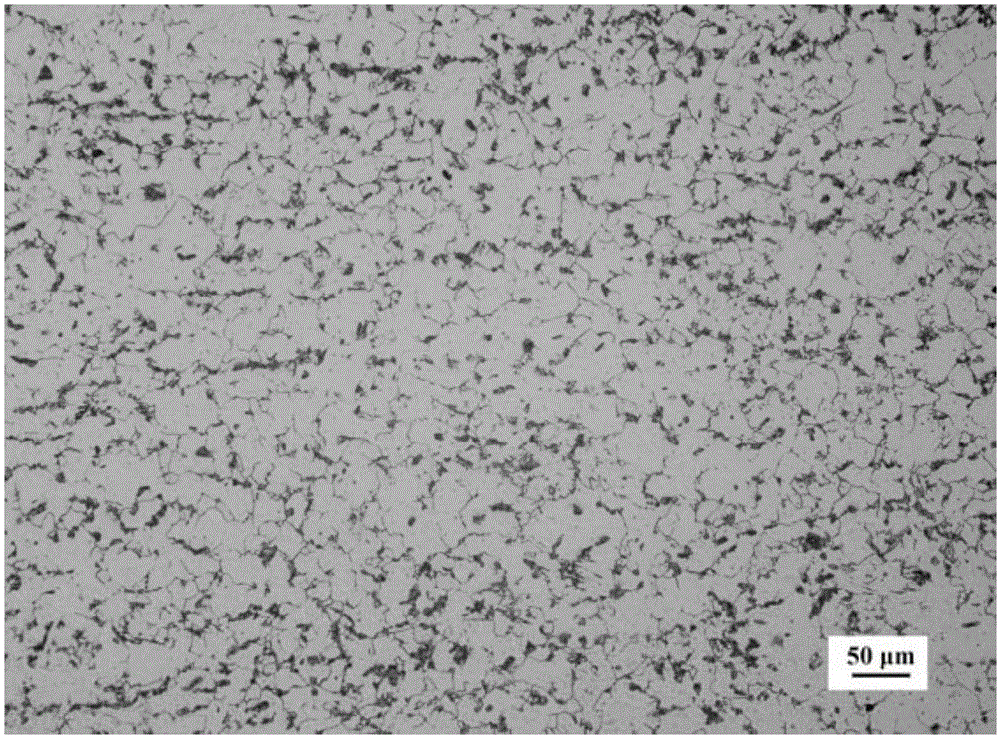

[0026] The pearlite grinding, polishing and erosion reagent of the present invention is prepared from 25 parts by mass of distilled water, 47.12 parts of hydrogen peroxide solution, 2.28 parts of hydrofluoric acid solution and 2.8 parts of oxalic acid.

[0027] The mass percent concentration of hydrogen peroxide in the hydrogen peroxide solution is 30%.

[0028] The mass percent concentration of hydrofluoric acid in the hydrofluoric acid solution is 40%.

Embodiment 2

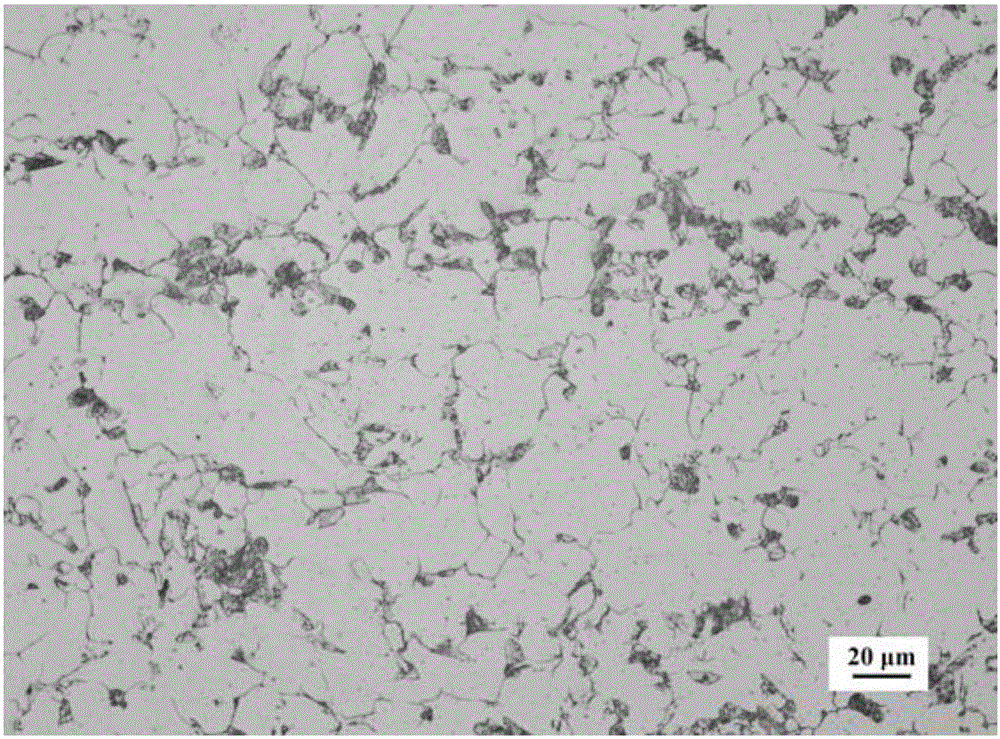

[0030] The pearlite grinding, polishing and erosion reagent of the present invention is prepared from 30 parts by mass of distilled water, 33.66 parts of hydrogen peroxide solution, 3.19 parts of hydrofluoric acid solution and 2 parts of oxalic acid.

[0031] The mass percent concentration of hydrogen peroxide in the hydrogen peroxide solution is 30%.

[0032] The mass percent concentration of hydrofluoric acid in the hydrofluoric acid solution is 40%.

Embodiment 3

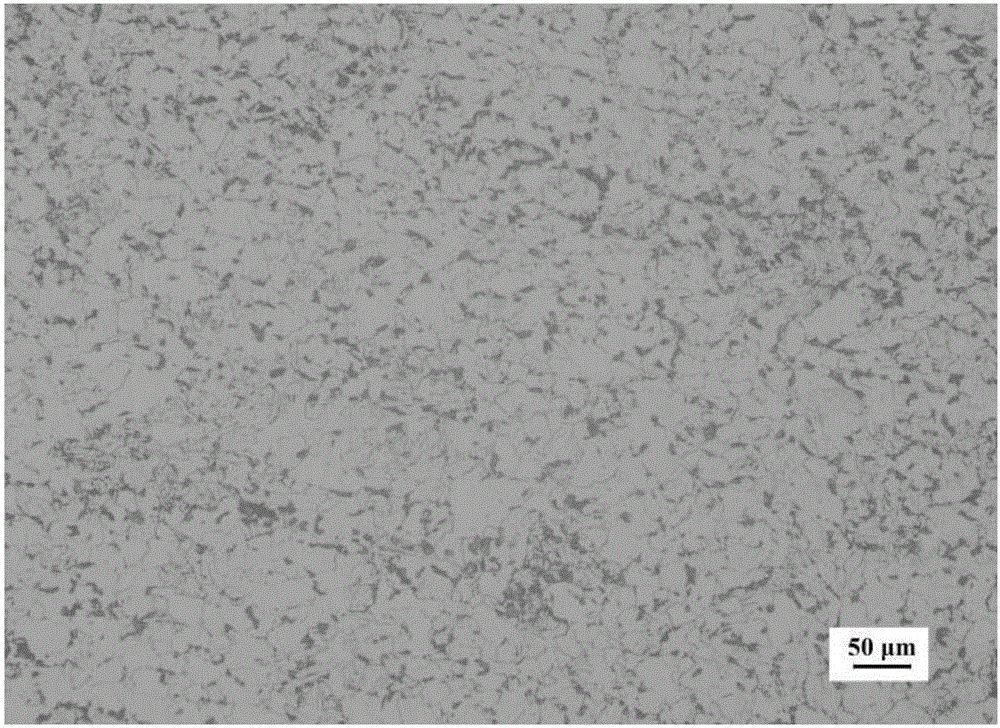

[0034] The pearlite grinding and polishing erosion reagent of the present invention is prepared from 26 parts by mass of distilled water, 38 parts of hydrogen peroxide solution, 2.5 parts of hydrofluoric acid solution and 2.3 parts of oxalic acid.

[0035] The mass percent concentration of hydrogen peroxide in the hydrogen peroxide solution is 30%.

[0036] The mass percent concentration of hydrofluoric acid in the hydrofluoric acid solution is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com