Dual-function cold-rolled steel coil off-line check station capable of uncoiling up and down

An inspection station, cold-rolled steel technology, applied in metal rolling, metal rolling, length measuring devices, etc., can solve the problems of difficulty in meeting the inspection rhythm of high-end home appliance panels and automobile panels, cumbersome operations, and many steps, and achieve investment. Small, easy to maintain, and scratch-resistant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

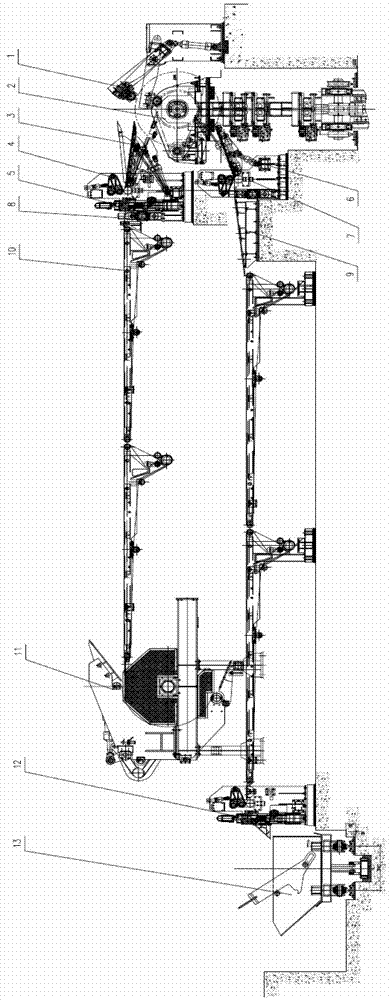

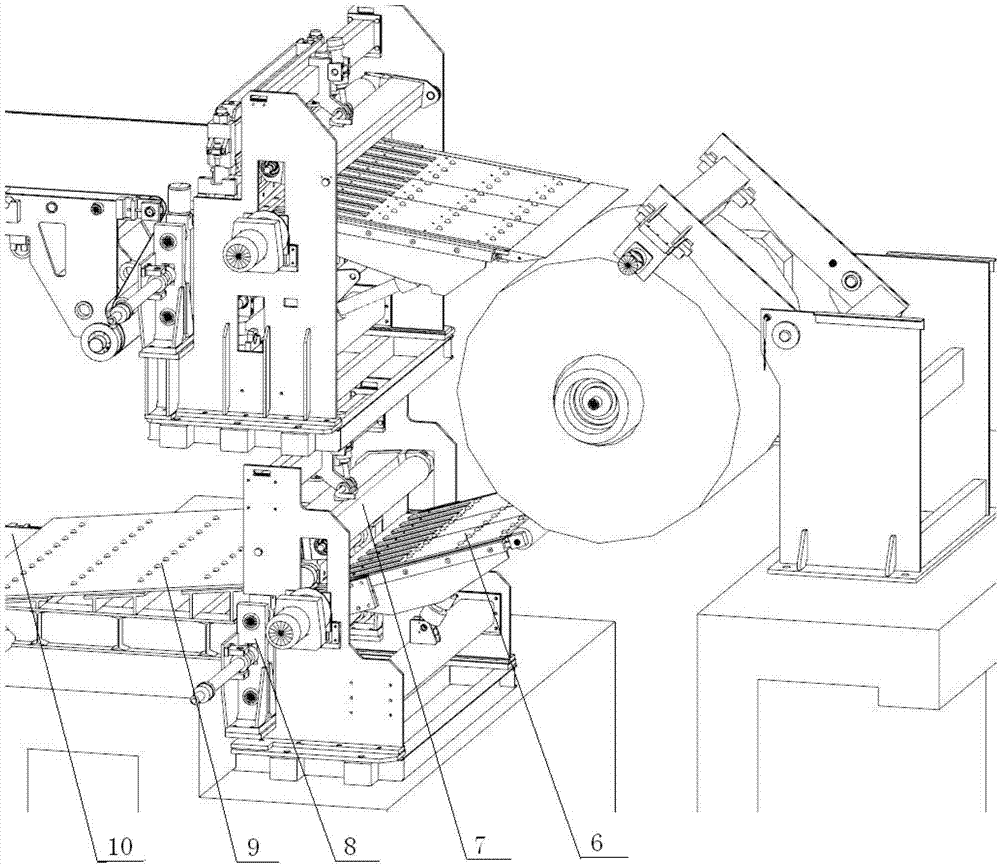

[0019] Depend on figure 1 A dual-function cold-rolled steel plate inspection station that can be uncoiled up and down is shown. It adopts a traditional double-layer flat structure. Take-up machine 2, upper uncoiling guide plate 3, 1# pinch roller 4, 1# cross-cut shear 5, lower uncoiling guide plate 6, 2# pinch roller 7, centering device 8, guide plate table 9, conveyor belt 10, steering device 11. 2# cross-cut shear 12, waste transport device 13.

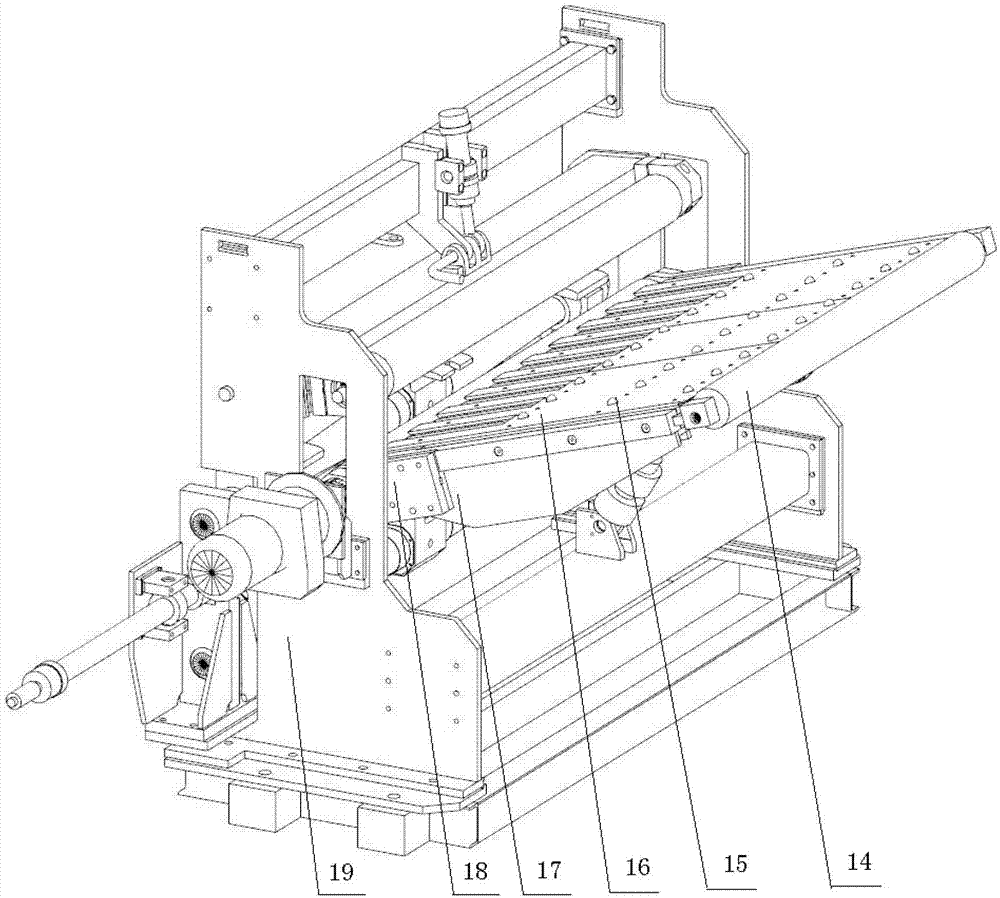

[0020] Lower uncoiling guide plate 6: it is divided into two parts, traversing beam 16 and rotating beam 17, which are welded workpieces. Slide rails are arranged on the side of rotating beam 17, and traversing beam 16 can slide therein. The surface paving material of the traverse beam 16 and the rotating beam 17 in contact with the steel plate is a PA 6 nylon plate, on which the universal ball bearing 15 is inlaid. There is a pressure roller 14 near the steel coil side of the traverse beam 16, and the surface of the pressure roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com