Wheel-track composite substation inspection robot autonomous obstacle-surpassing system and control method

An inspection robot and control method technology, applied in two-dimensional position/channel control and other directions, can solve the problems of low operation efficiency of crawler robots, inability to apply substation inspection robots, and difficulty in meeting the requirements of efficient robot inspection, etc. Achieve the effect of precise control, easy expansion and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

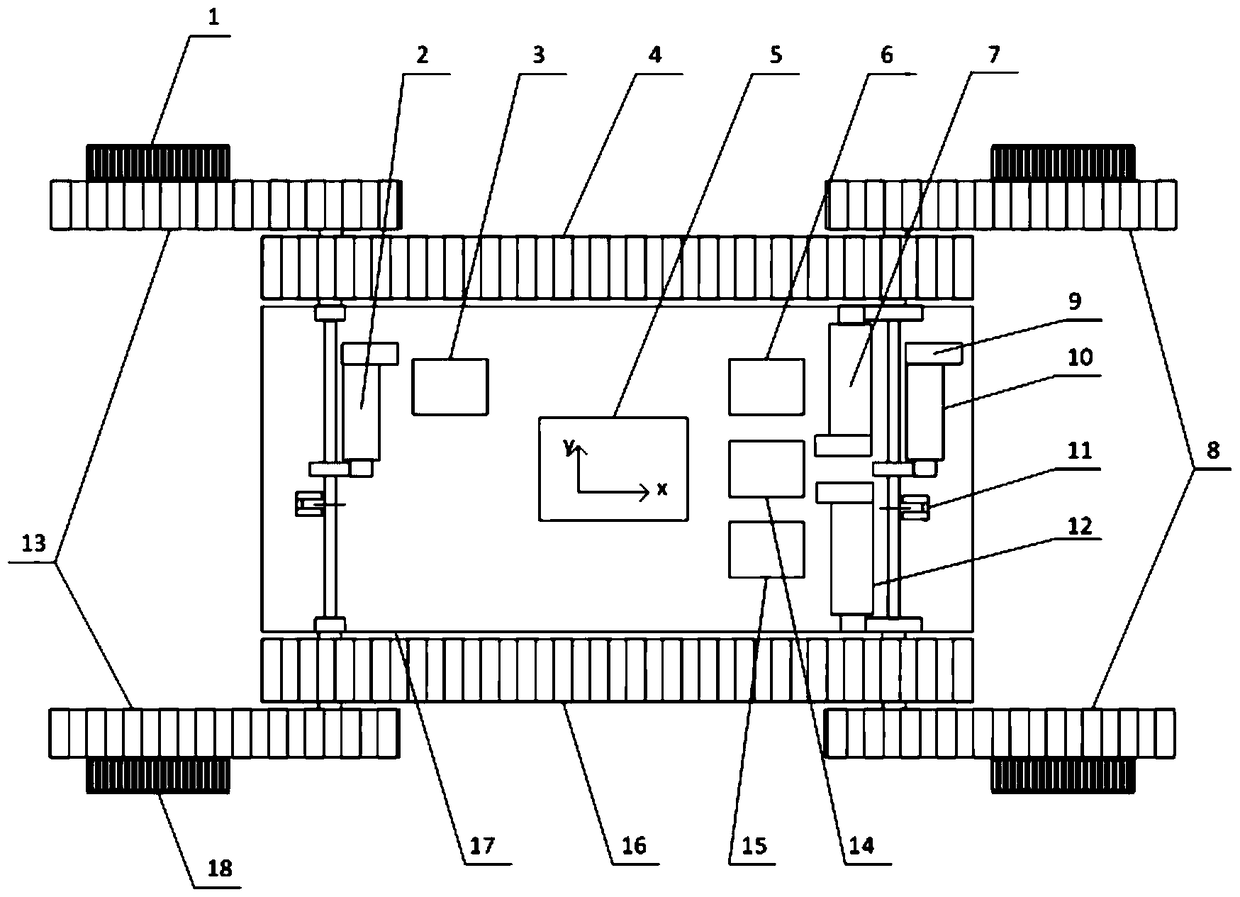

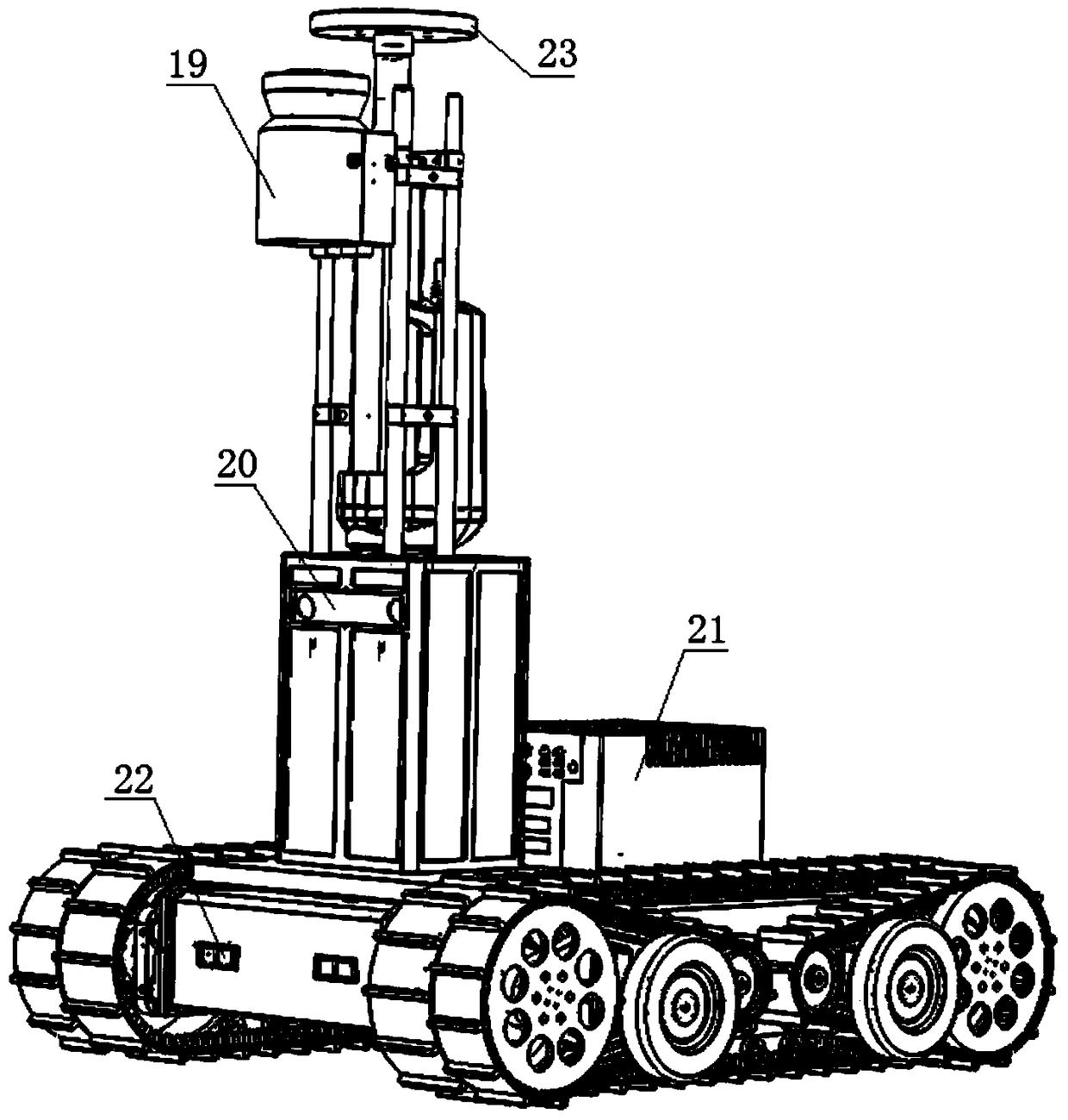

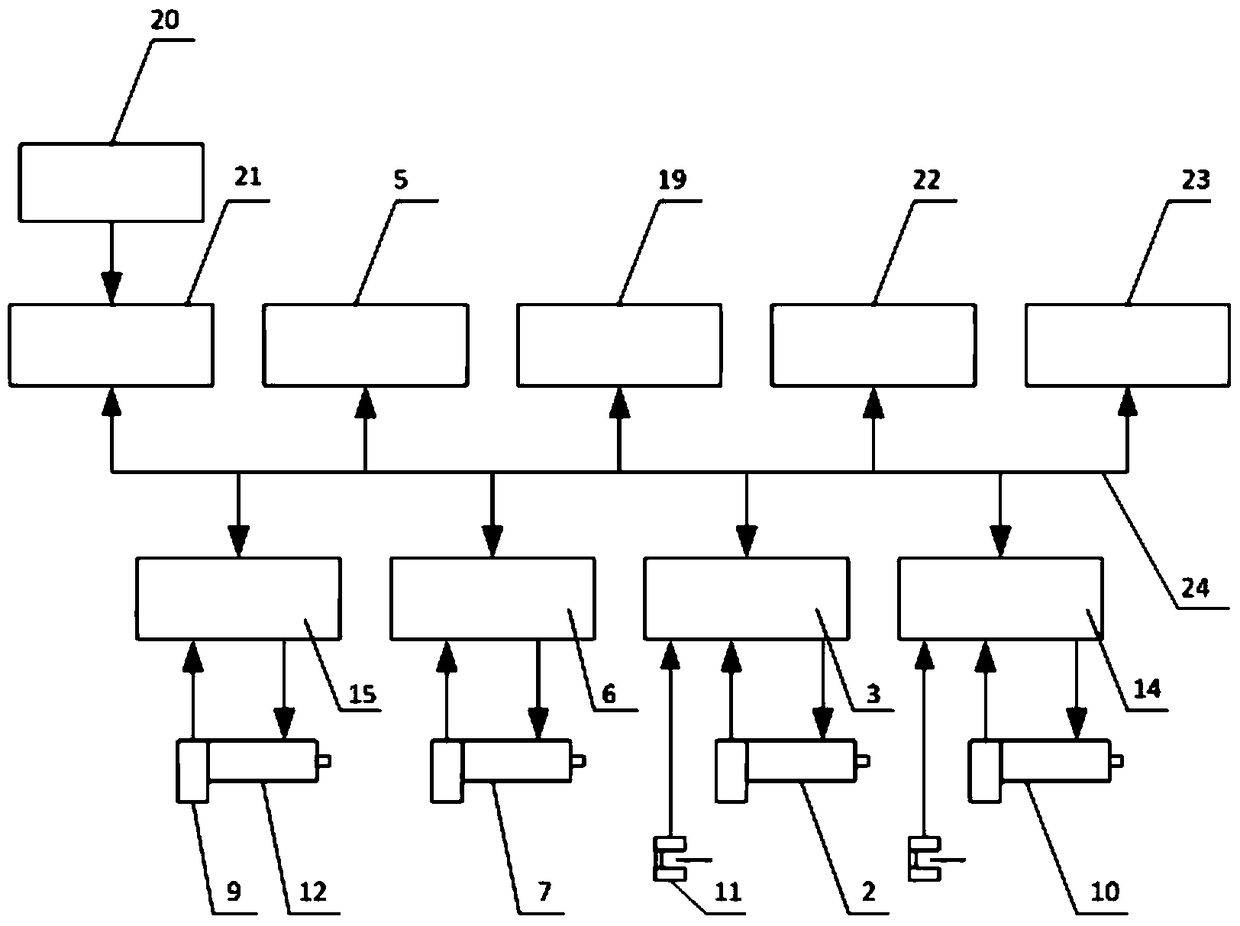

[0077] A four-arm wheel-track composite robot chassis includes a robot control box (17), a crawler walking unit, a wheel walking unit, an obstacle-crossing arm unit and a driving motor. Wherein the crawler walking unit comprises a left walking crawler (4) and a right walking crawler (16) installed on both sides of the control box. The wheeled traveling unit comprises two left traveling wheels (1) and two right traveling wheels (18). The obstacle-surmounting support arm unit includes two front support arms (8) installed at the front end of the control box body and two rear support arms (13) installed at the rear end of the control box body. The drive motors include a left travel drive motor (7), a right travel drive motor (12), a front support arm drive motor (10) and a rear support arm drive motor (2).

[0078] Wherein, walking wheel is installed on the front support arm (8) and the rear support arm (13) respectively. The two traveling wheels installed on the front support a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com