Trimming device for broom bristle production

A technology of trimming device and bristles, applied in grinding/polishing safety devices, brushes, separation methods, etc., can solve the problems of low practicability, inconvenience of different shapes of broom bristles, inconvenience of collection and cleaning of debris and impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028]下面对照附图,通过对实施例的描述,对本发明的具体实施方式如所涉及的各构件的形状、构造、各部分之间的相互位置及连接关系、各部分的作用及工作原理、制造工艺及操作使用方法等,作进一步详细的说明,以帮助本领域的技术人员对本发明的发明构思、技术方案有更完整、准确和深入的理解。

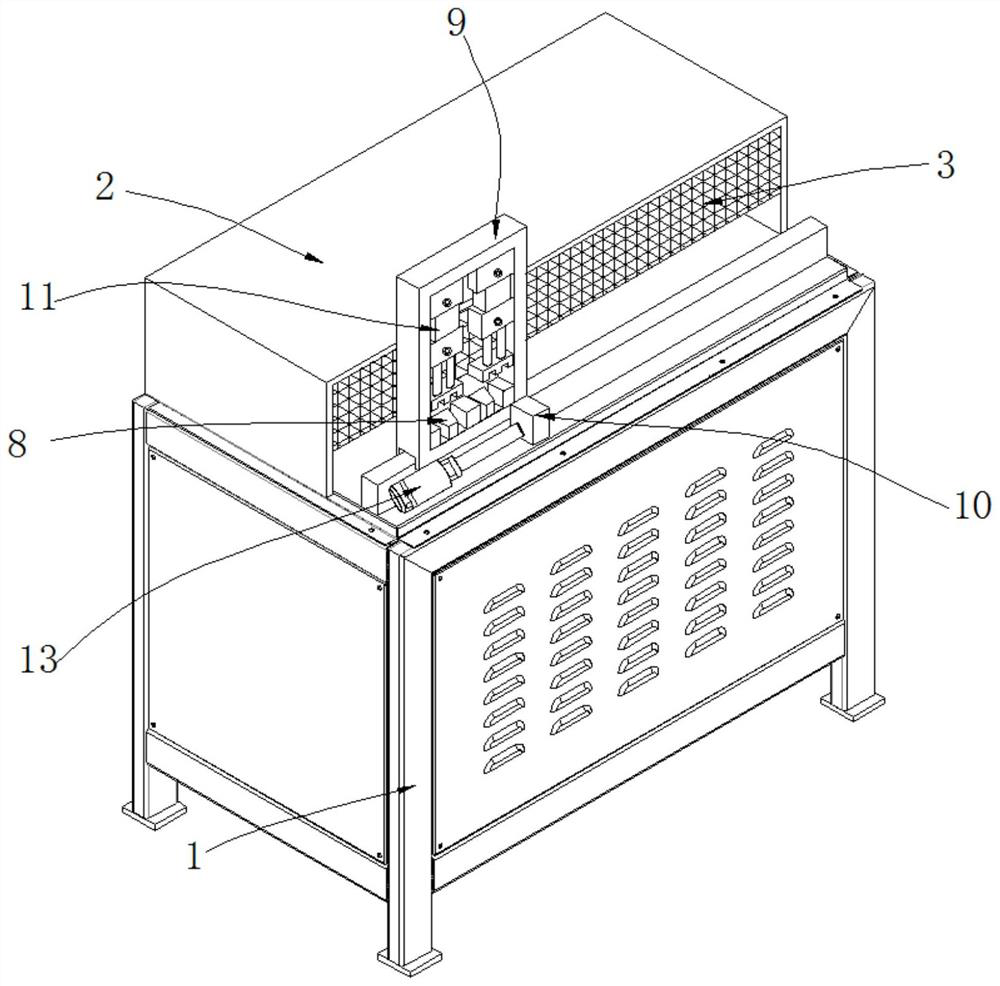

[0029]图1-6所示的一种用于扫把刷毛生产中的修剪装置,切割箱体1、过滤挡板3和夹紧滑动机构9,切割箱体1的顶端设置有固定框体2;

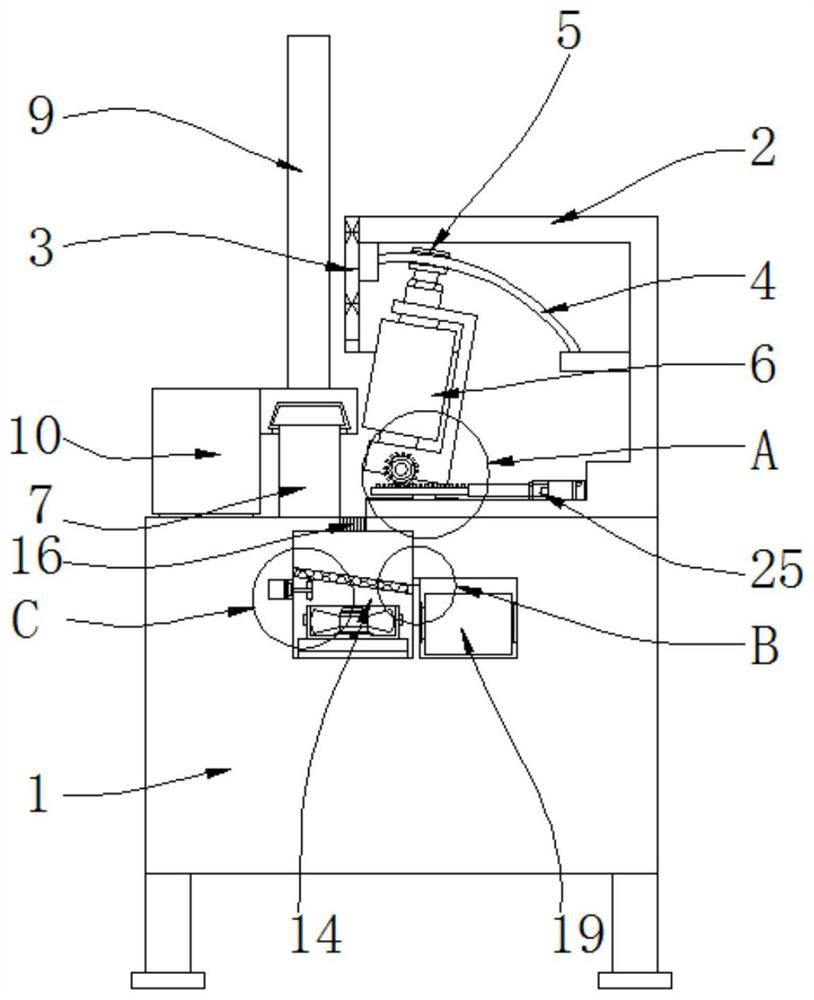

[0030]切割箱体1的两端通过轴承安装有与切割设备本体6相连接的固定轴22,且固定轴22的外壁设置有多个定位齿轮23,通过定位齿轮23带动固定轴22发生翻转,从而固定轴22带动切割设备本体6与毛刷板位置进行接触,而通过变换切割设备本体6的旋转角度,进而便于对毛刷板的打磨形状进行调整;

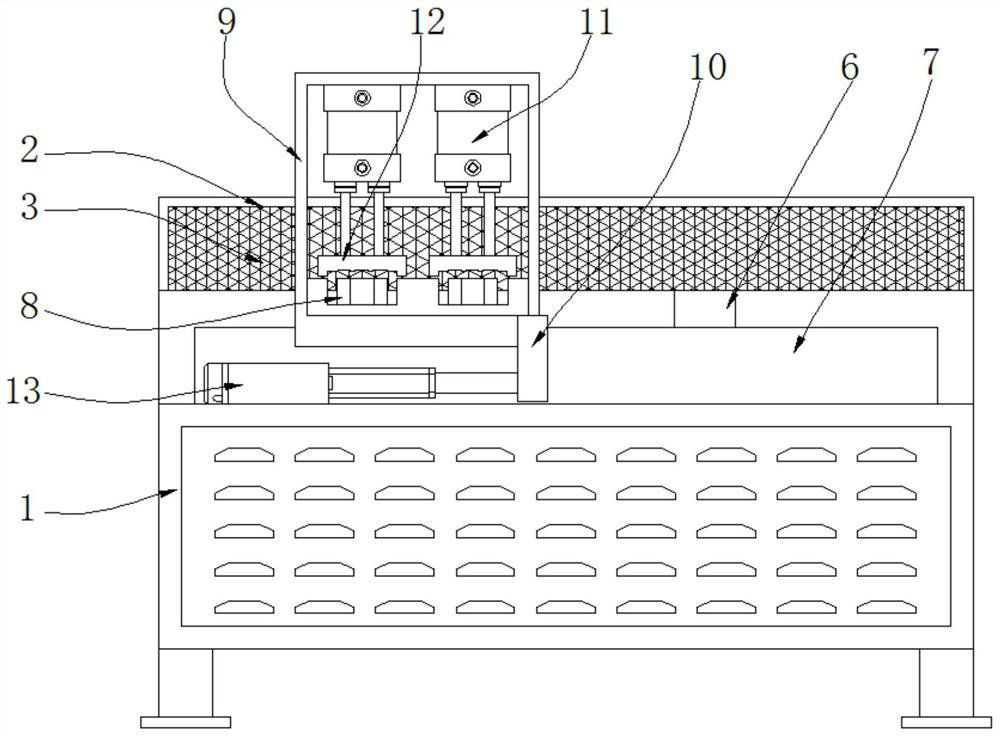

[0031]固定框体2的一侧设置有过滤挡板3,固定框体2内部的顶端设置有弧形滑杆4,且弧形滑杆4的外壁设置有滑块5,滑块5的底端设置有切割设备本体6,固定框体2内部底端设置有用于移动切割设备本体6位置的旋转机构;

[0032]旋转机构包括固定框体2的顶端设置有固定轴22,且固定轴22内部设置有与定位齿轮23外壁相啮合的齿条24,固定框体2顶端设置有电动伸缩杆25,且电动伸缩杆25输出端与齿条24的一端相连接,通过启动电动伸缩杆25推动齿条24在固定轴22内发生移动,从而齿条24与定位齿轮23的外壁相啮合,进而便于驱动切割设备本体6的移动角度进行调整;

[0033]切割箱体1的顶端设置有第一滑轨7,且第一滑轨7的顶端设置有夹紧滑动机构9;

[0034]夹紧滑动机构9内部的顶端设置有气缸11,且气缸11的输出端设置有夹紧块12,通过启动气缸11带动夹紧块12对毛刷板进行快速夹紧固定;

[0035]夹紧滑动机构9内部的底端设置有固定座8,且固定座8外壁设置有防滑纹,通过将毛刷板固定在固定座8外壁,而通过固定座8防滑纹定位了毛刷板的位置;

[0036]切割箱体1顶端设置有用于夹紧滑动机构9位置的往复移位机构;

[0037]移位机构包括切割箱体1和液压伸缩杆13,切割箱体1的顶端设置有液压伸缩杆13,且液压伸缩杆13的输出端设置有连接板10,连接板10后壁与夹紧滑动机构9的外壁相连接,该结构则启动液压伸缩杆13通过连接板10带动夹紧滑动机构9在第一滑轨7内移动,从而便于带动夹紧后的毛刷板进行移位至...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com