Patents

Literature

32results about How to "Adjust the grinding angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

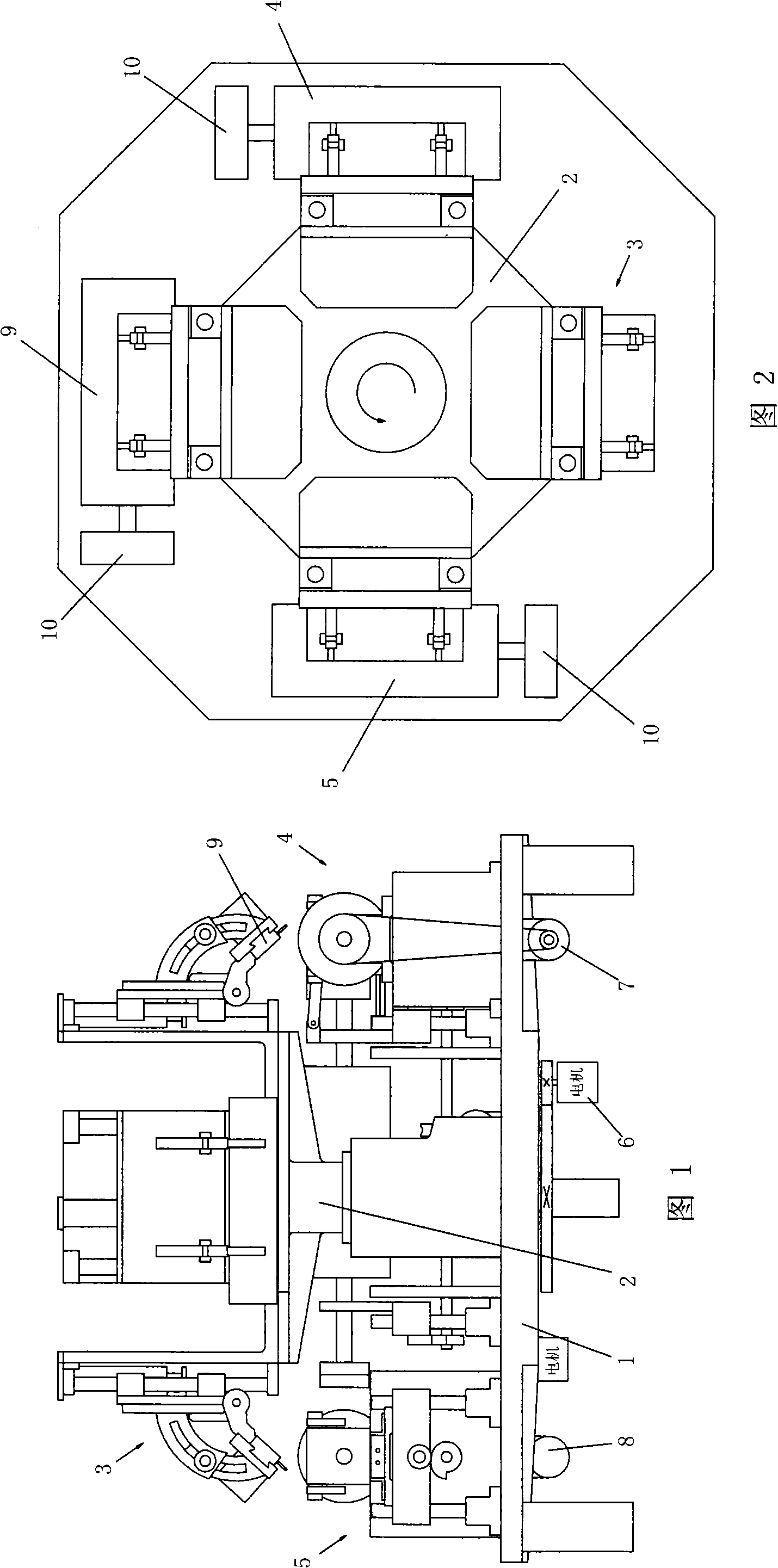

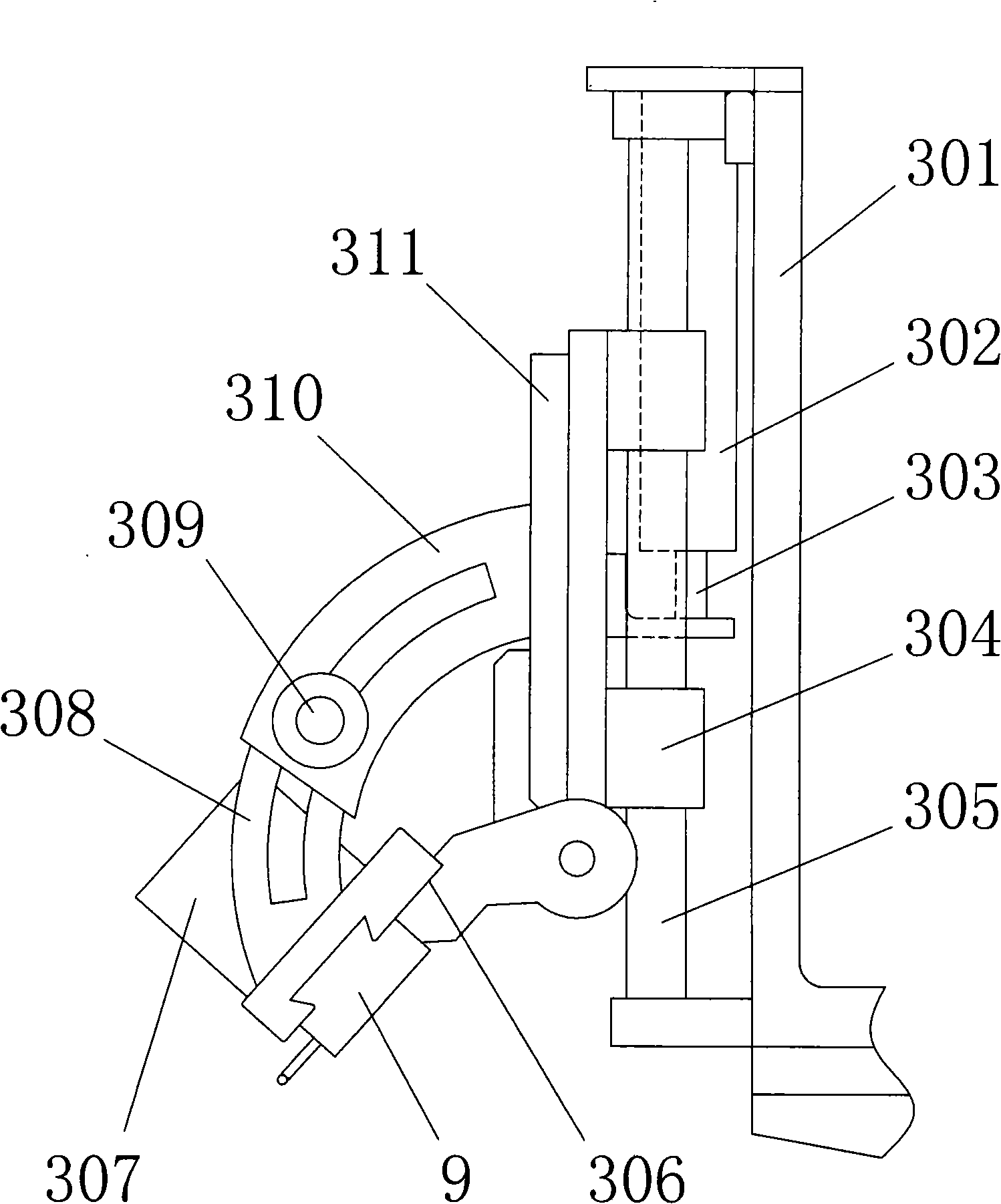

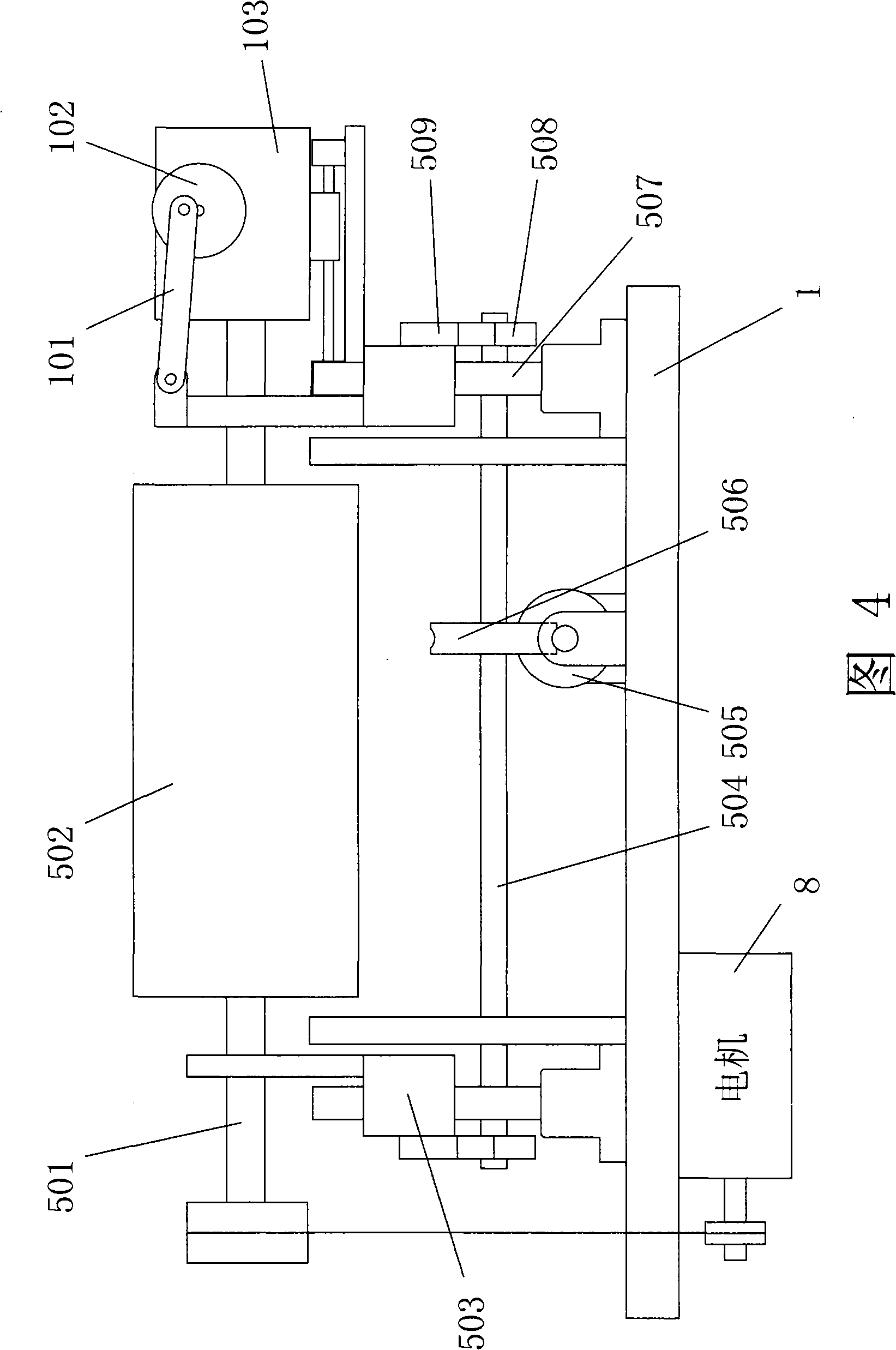

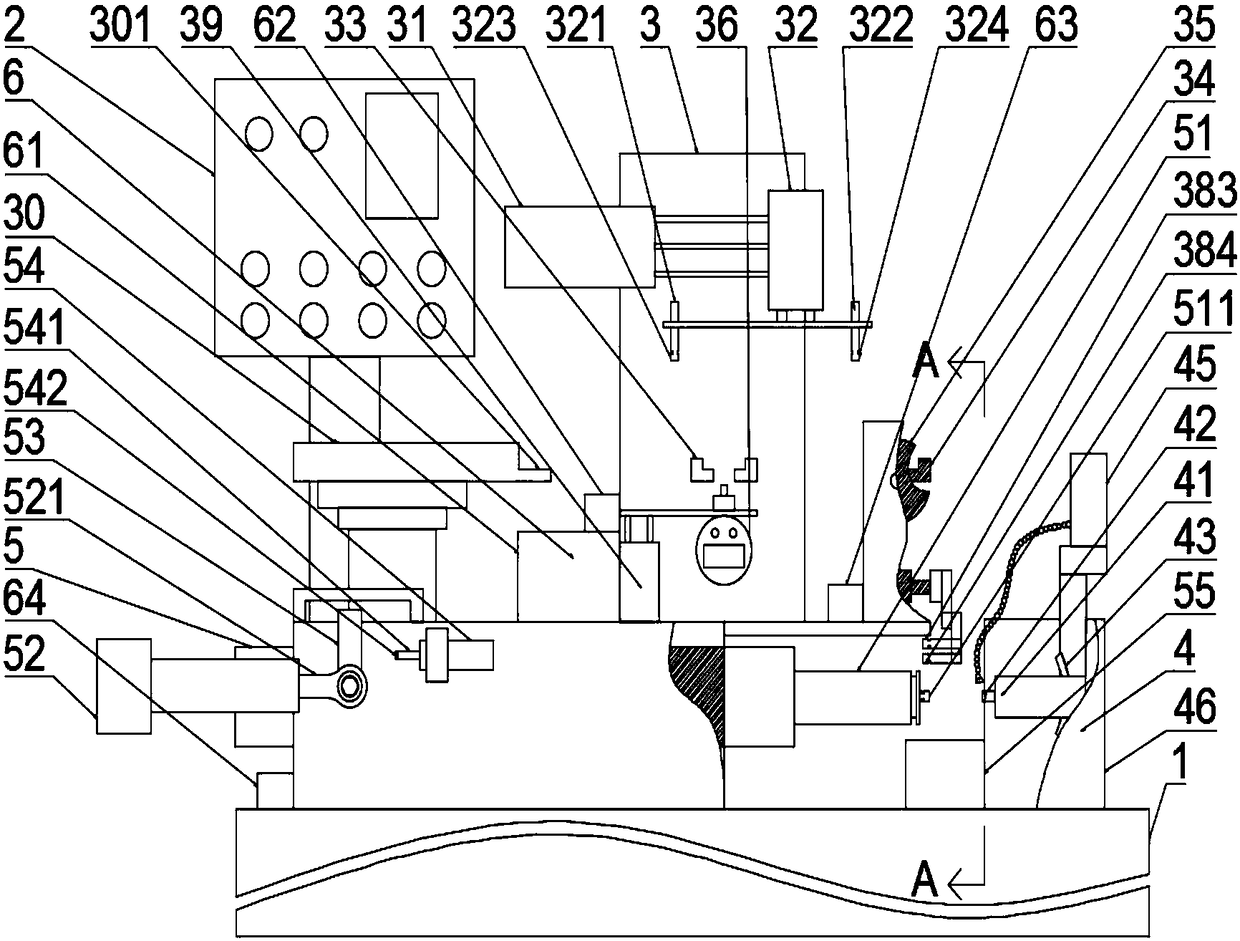

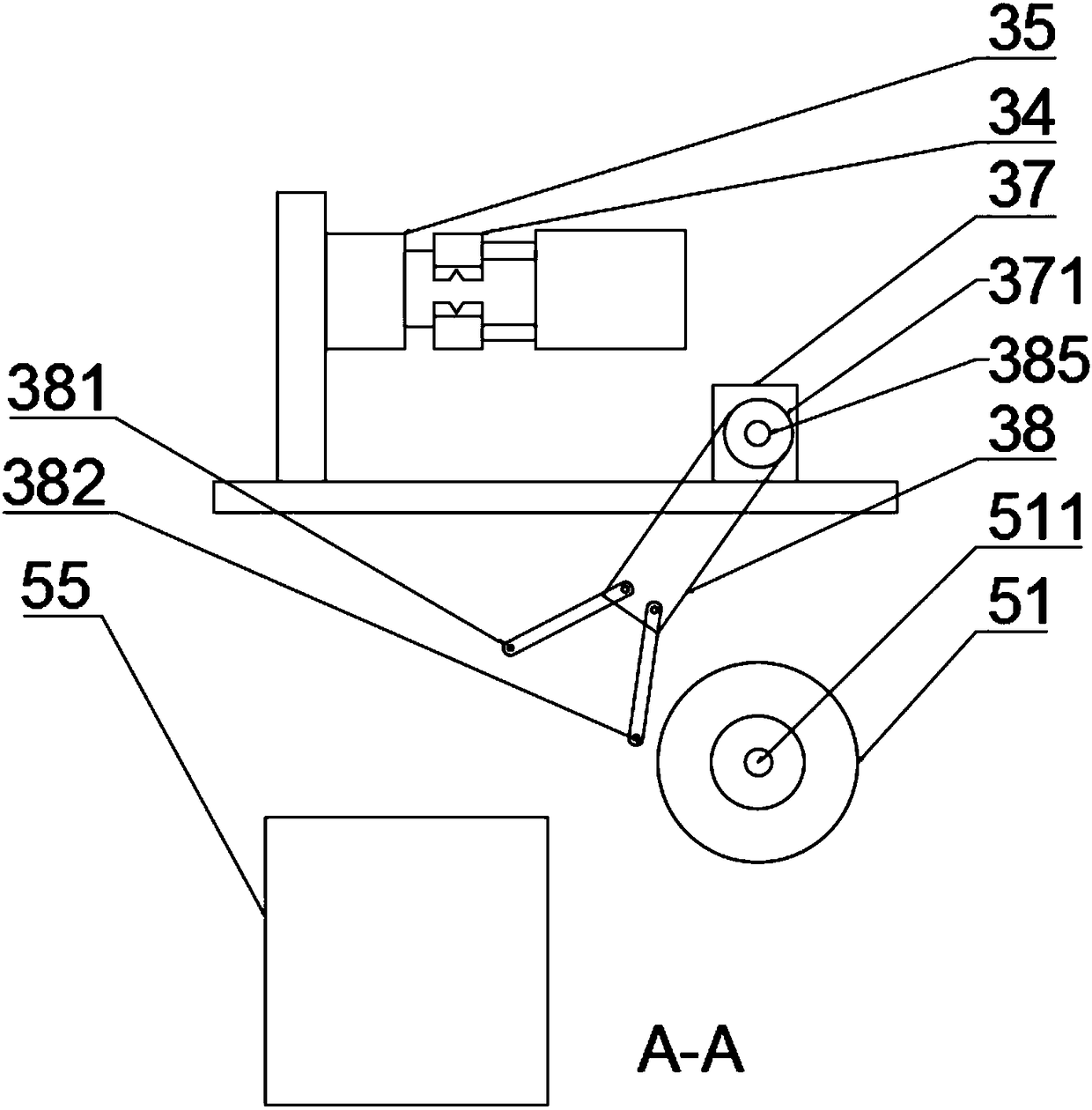

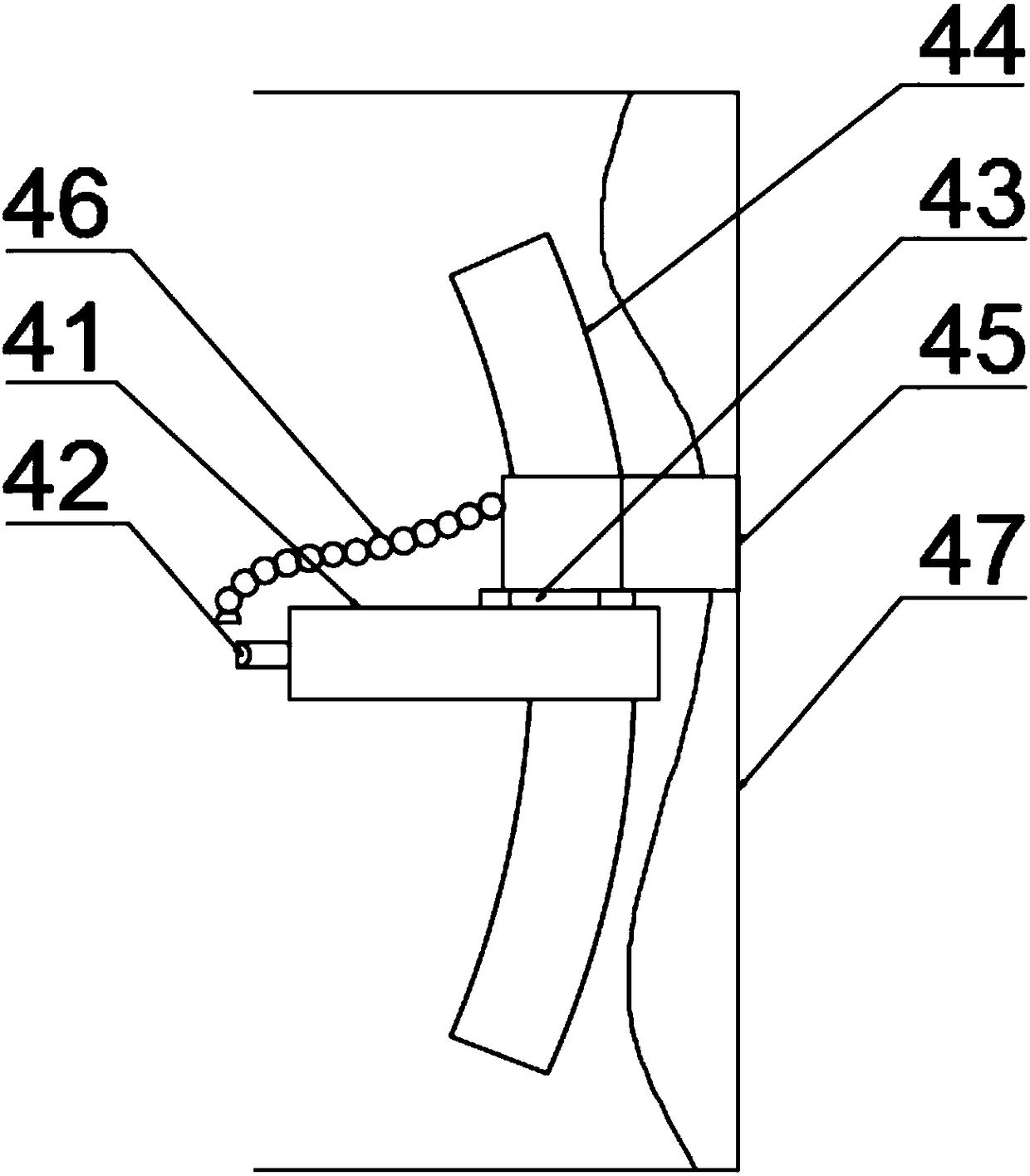

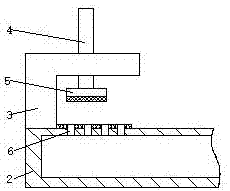

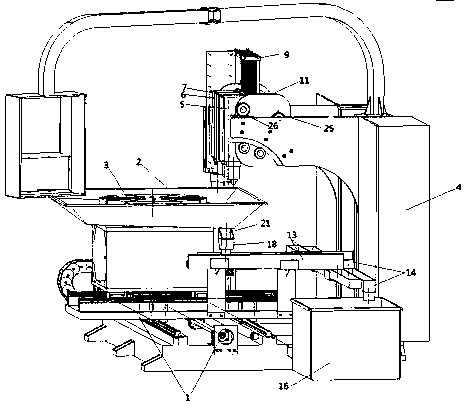

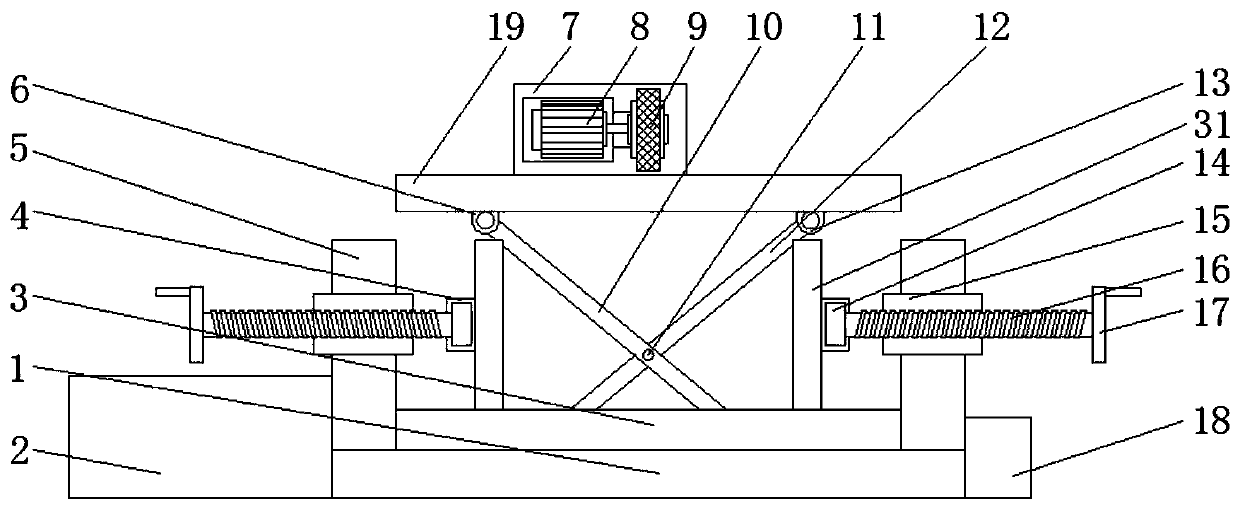

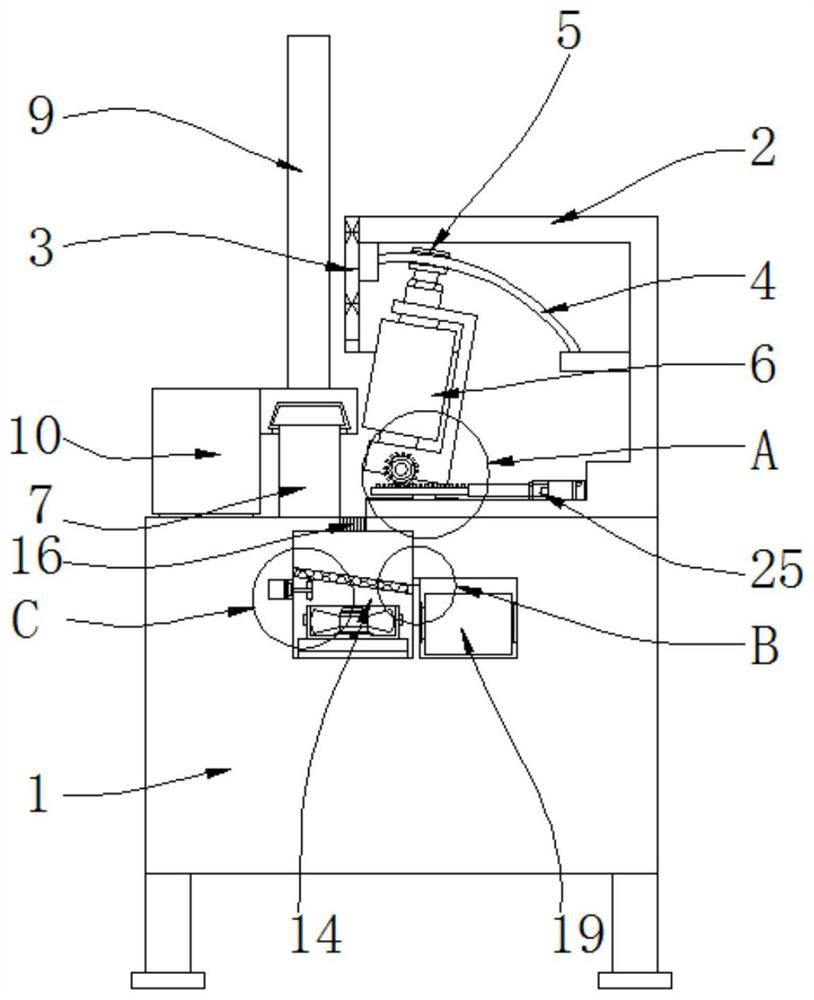

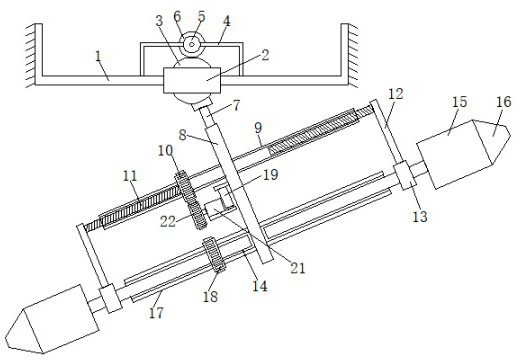

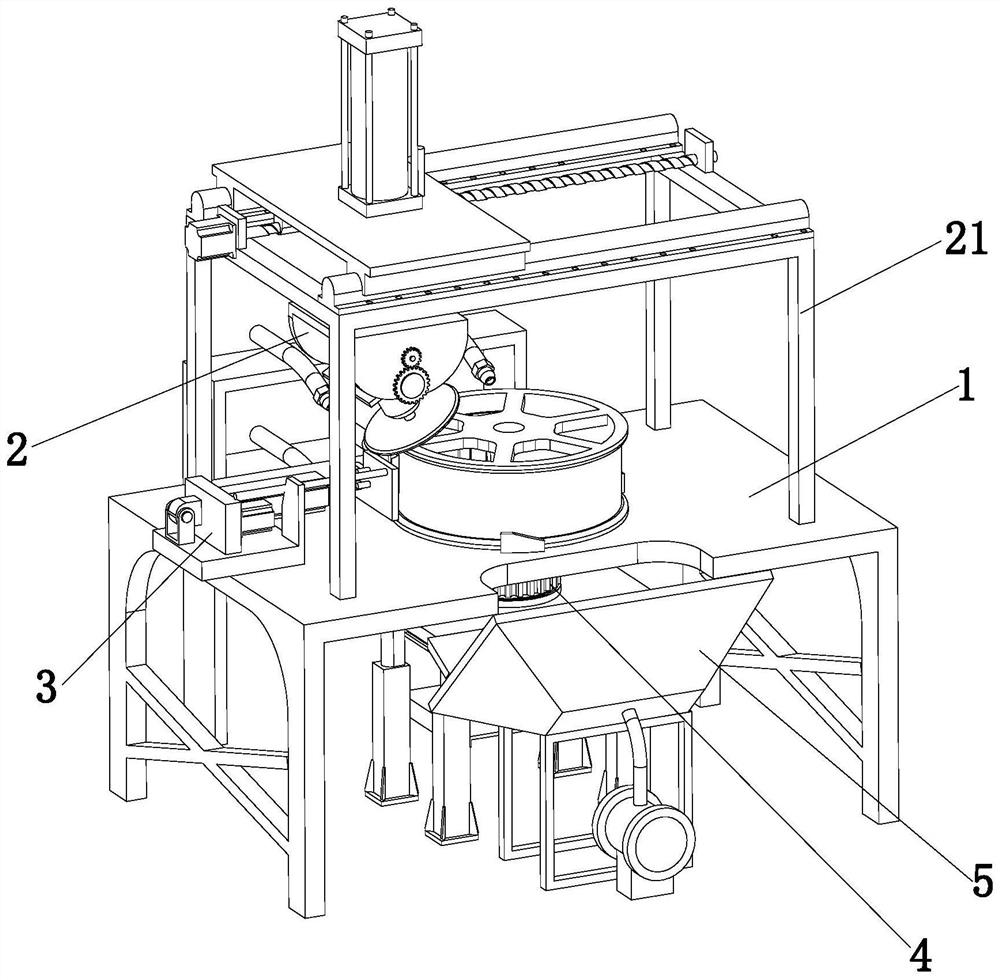

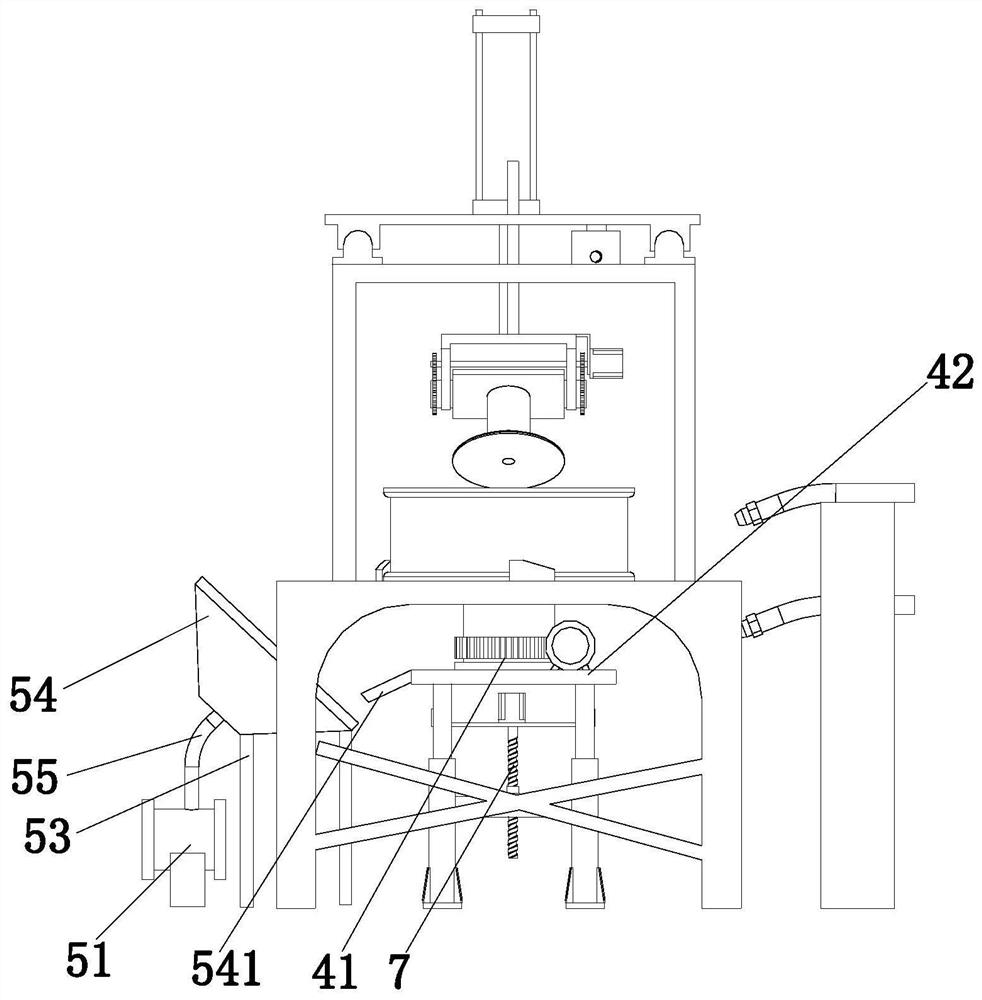

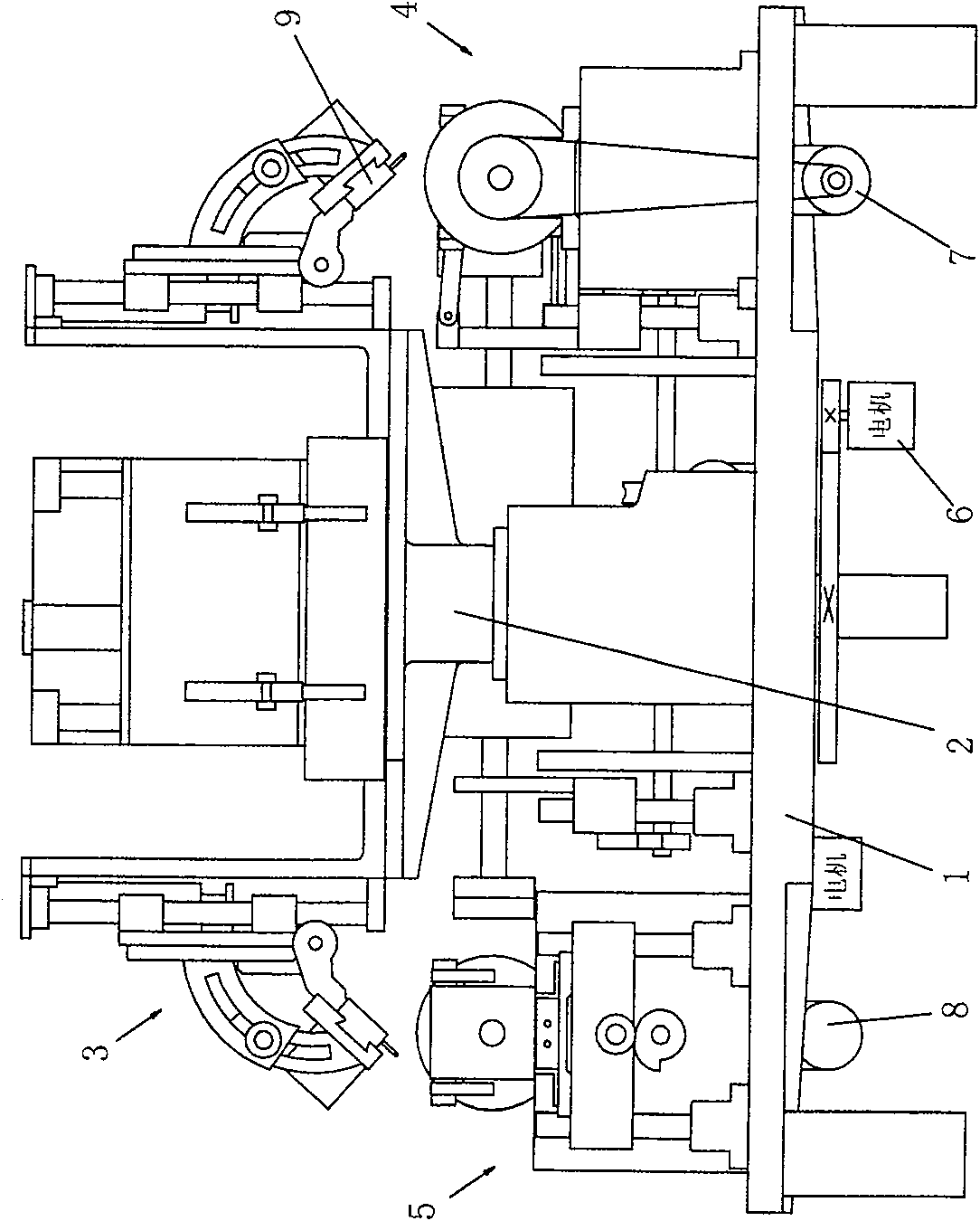

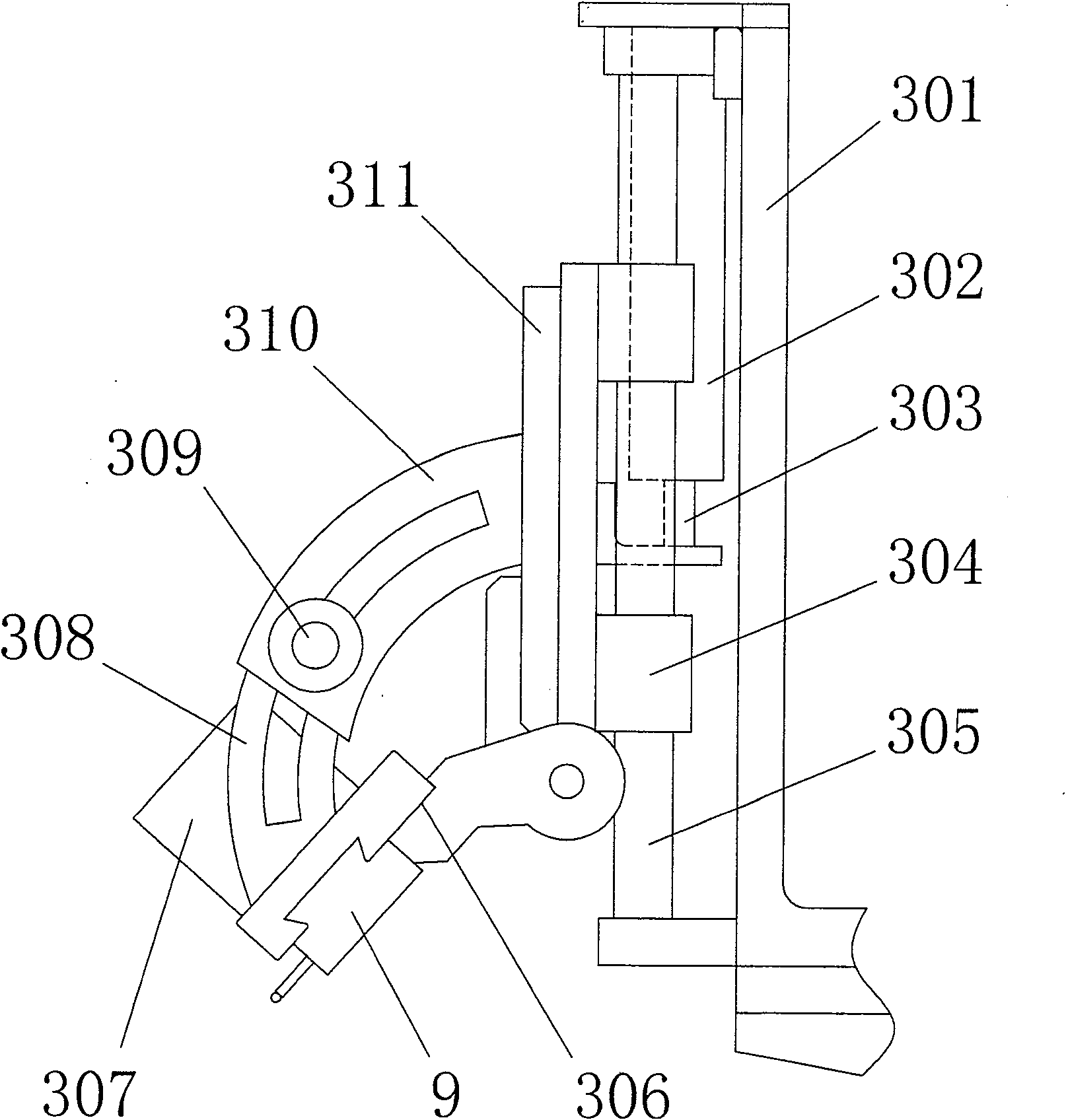

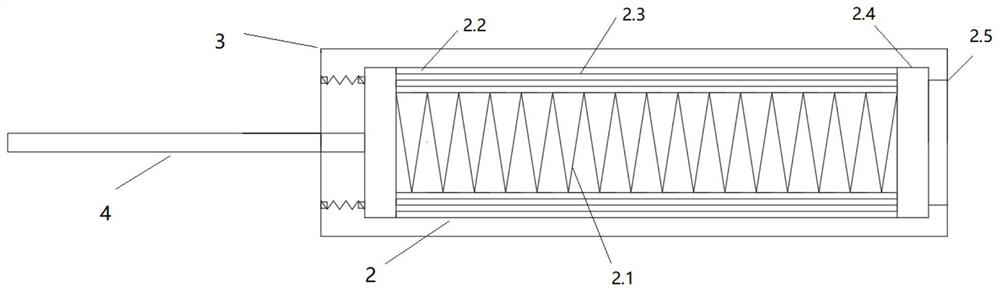

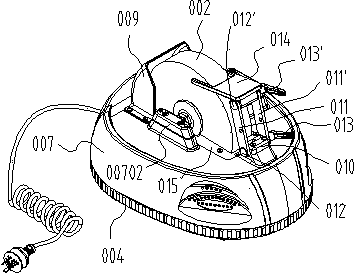

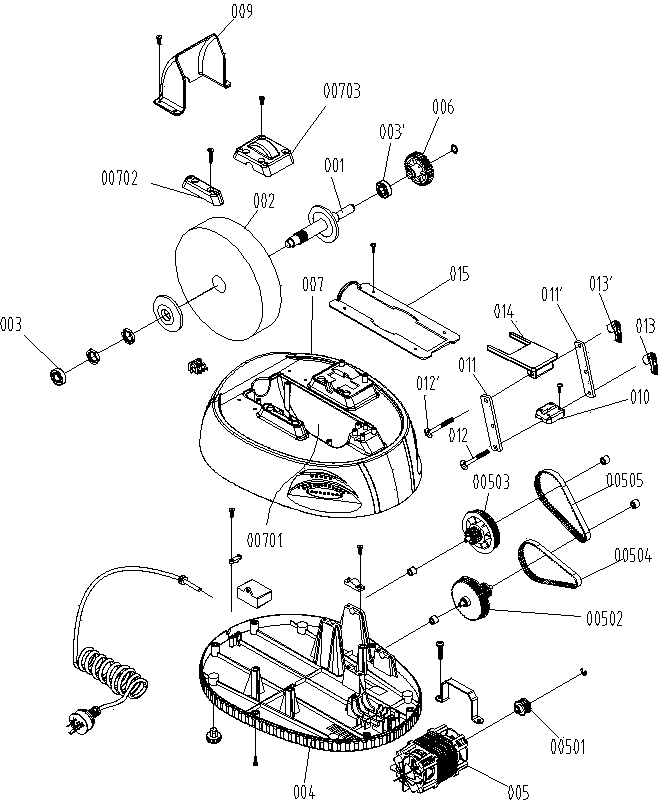

Four-station water drill inclined plane milling and casting machine

InactiveCN101269472AImprove processing efficiencyIncrease the number of single-group processingEdge grinding machinesSurface grindingEngineering

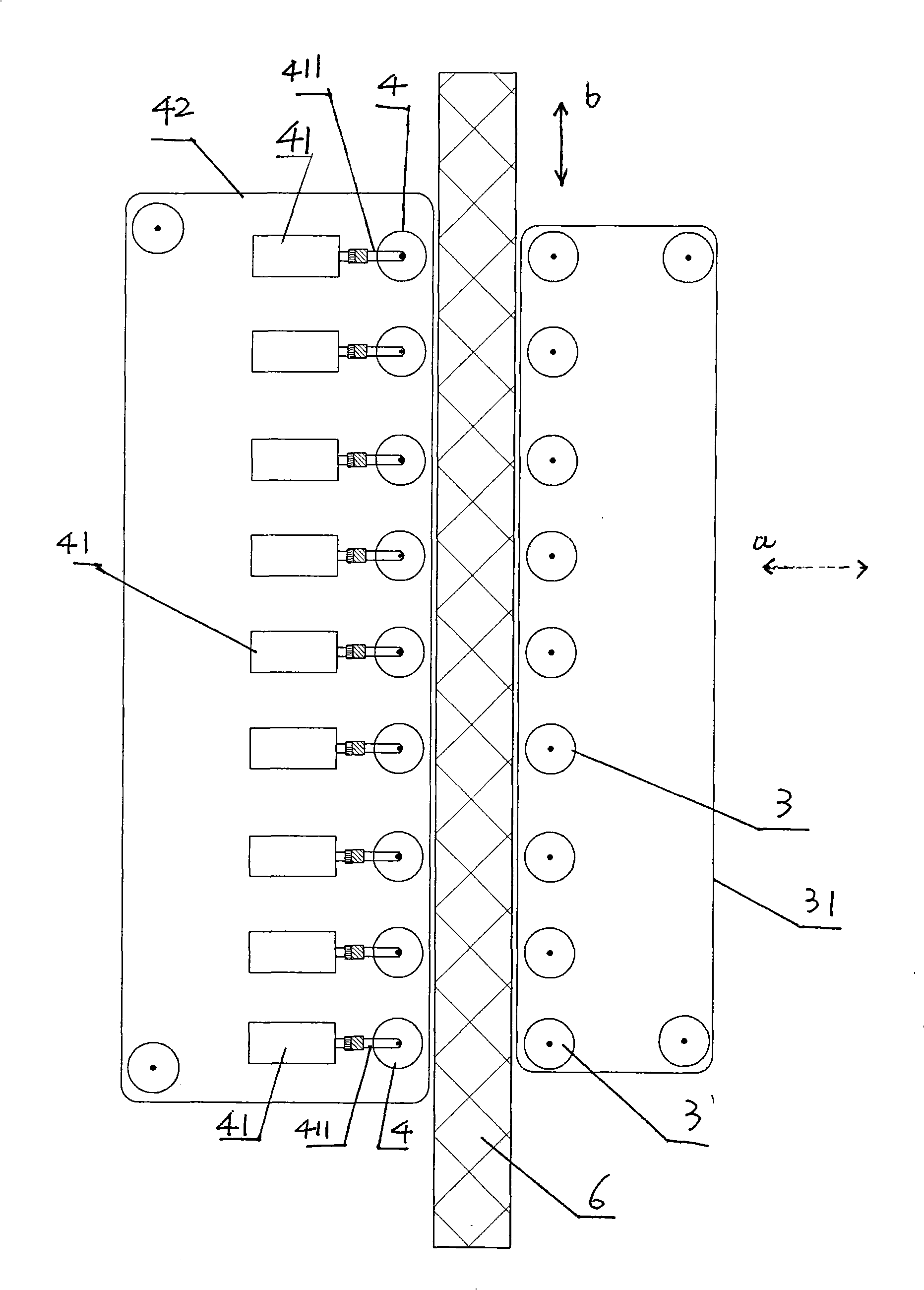

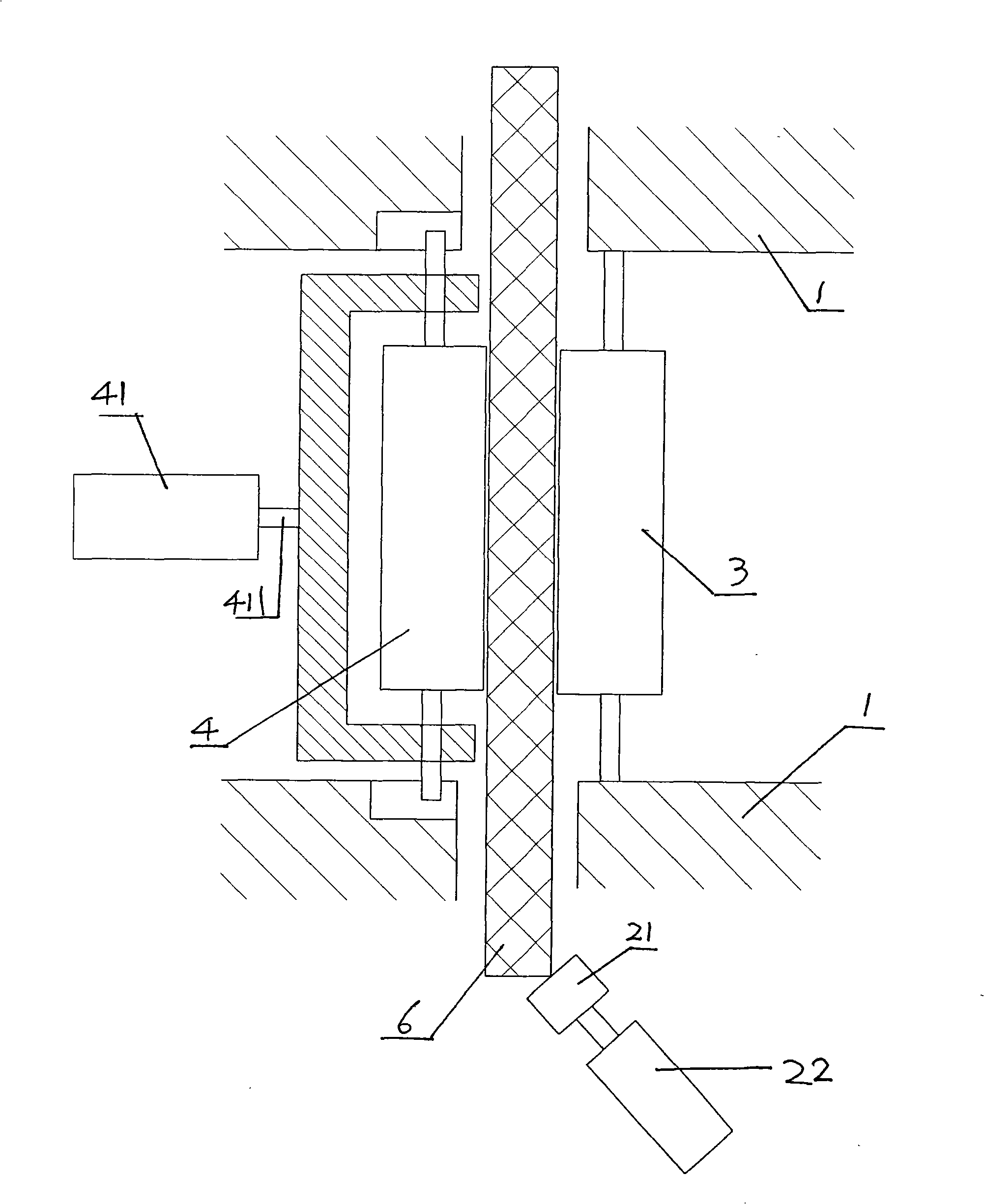

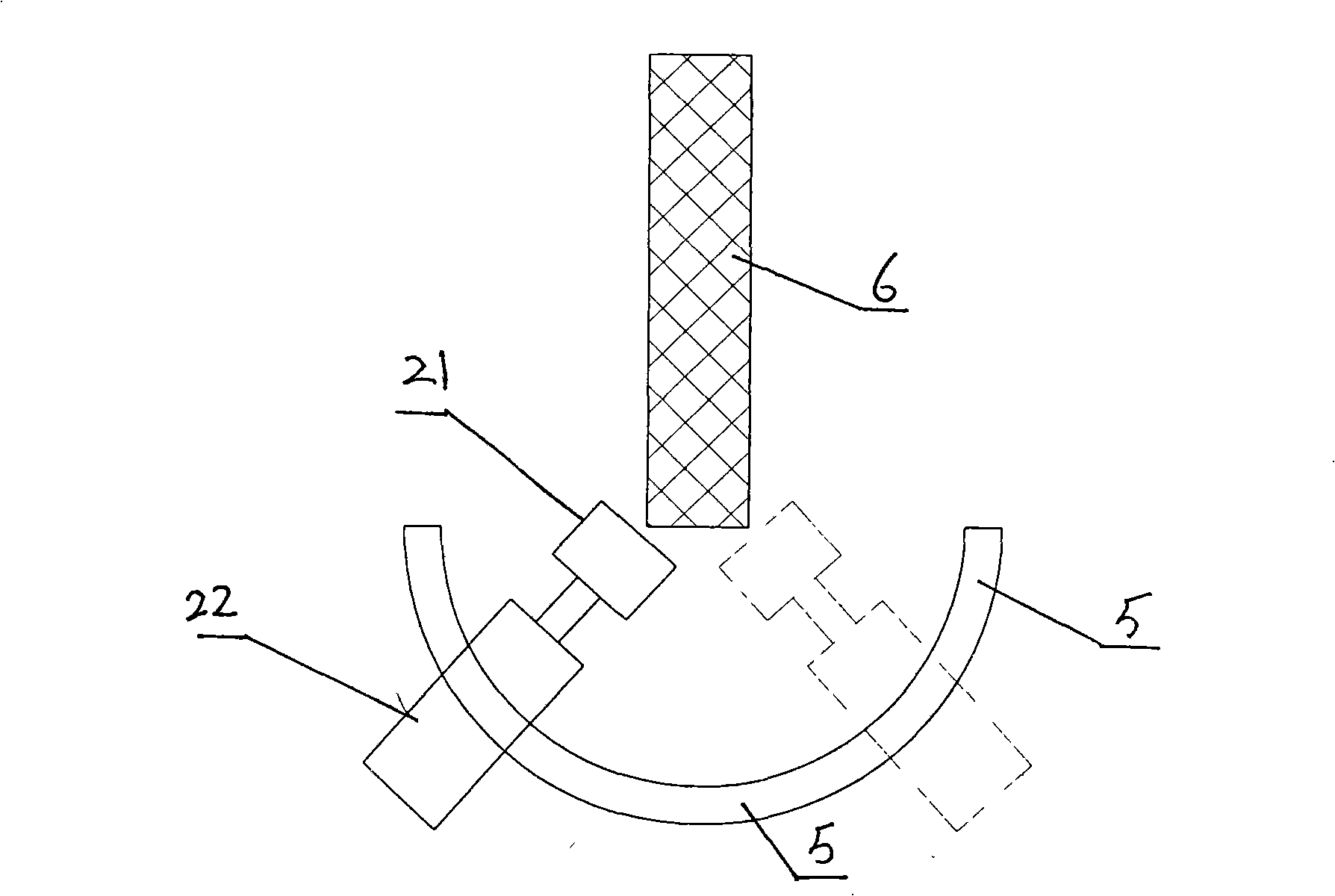

The invention relates to a quadruple work place water drill angular surface grinding machine, which comprises a framework, wherein, a rotation rack is arranged on the framework; four sides of the rotation rack are respectively provided with a ram head for fixing a cramping apparatus; a grinding work place, a rough polishing work place, a fine polishing work place and an up-down blanking vacancy are arranged on the framework and are respectively corresponding to the four ram heads; a grinding roller milling apparatus is arranged on the grinding work place; the rotation axis of the grinding roller is connected with a translational apparatus used for driving the grinding roller to do axial reciprocating translational motion; a group of burnishing roller polishing apparatuses is respectively arranged on the rough polishing work place and the fine polishing work place; the rotation axis of the burnishing roller is connected with the translational apparatus used for driving the burnishing roller to do axial reciprocating translational motion. The technical proposal adopts the grinding roller to grind and process water drill blank, so as to increase the single-unit processing amount of the water drill blank, and adopts the translational apparatus for driving the grinding roller to do axial reciprocating translational motion, so as to ensure even grinding of the water drill blank. Compared with the homogeneous equipment, the quadruple work place water drill angular surface grinding machine has the advantages of low cost, high production volume, good reliability, high processing efficiency, stable operation, convenient adjustment, etc.

Owner:虞雅仙

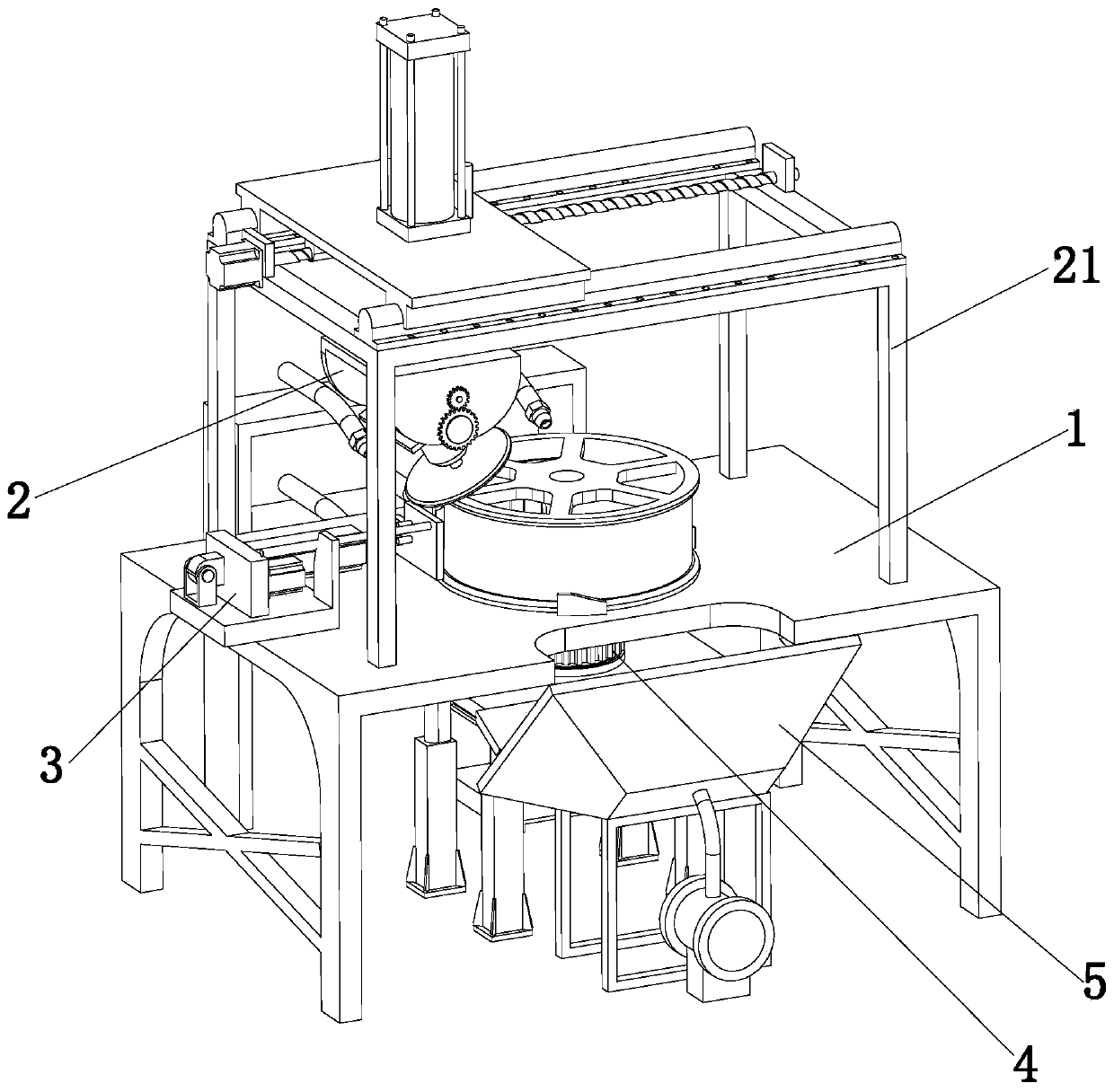

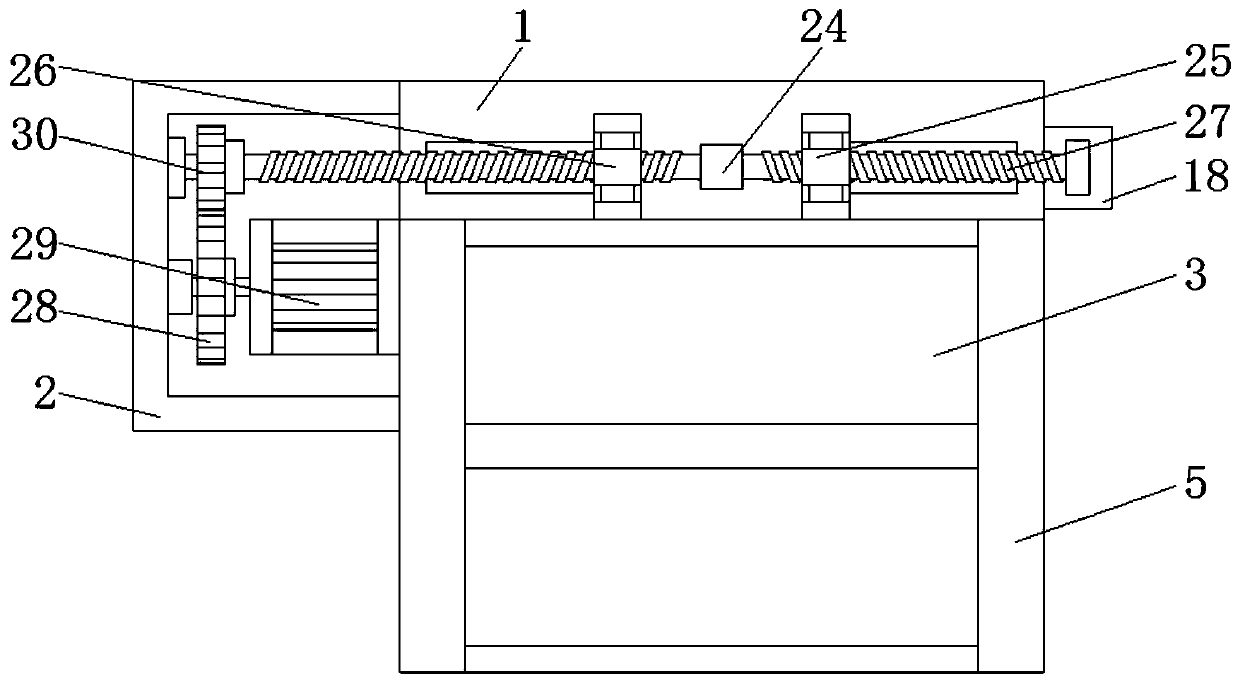

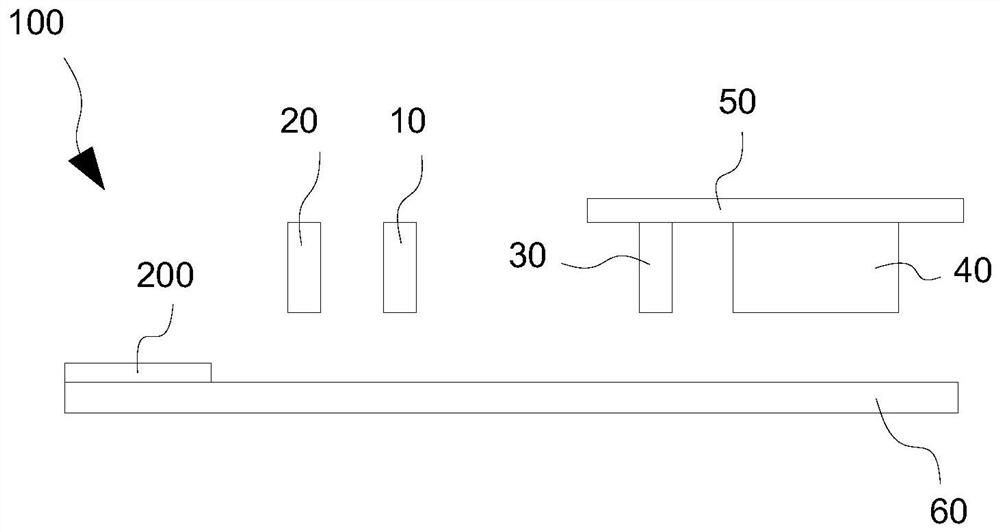

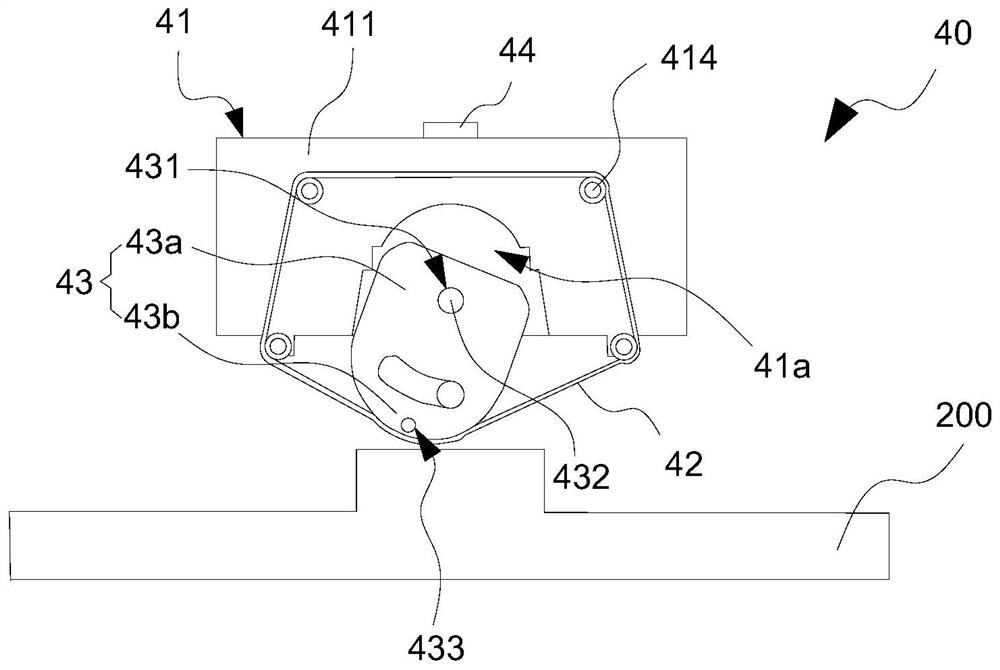

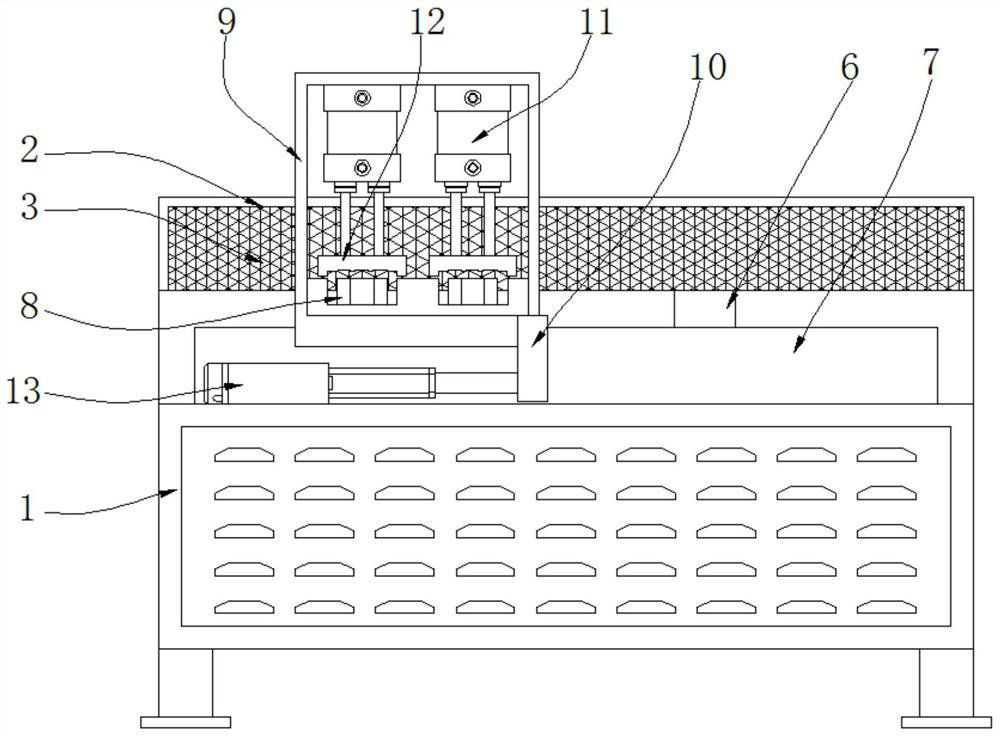

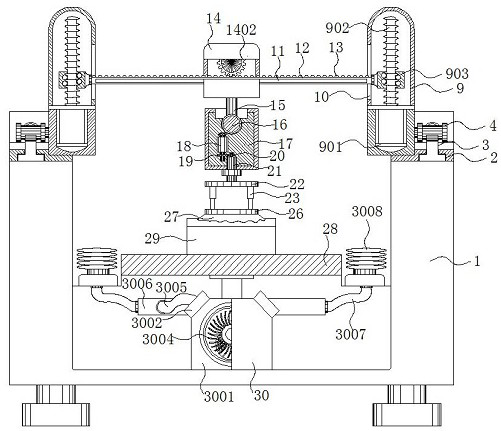

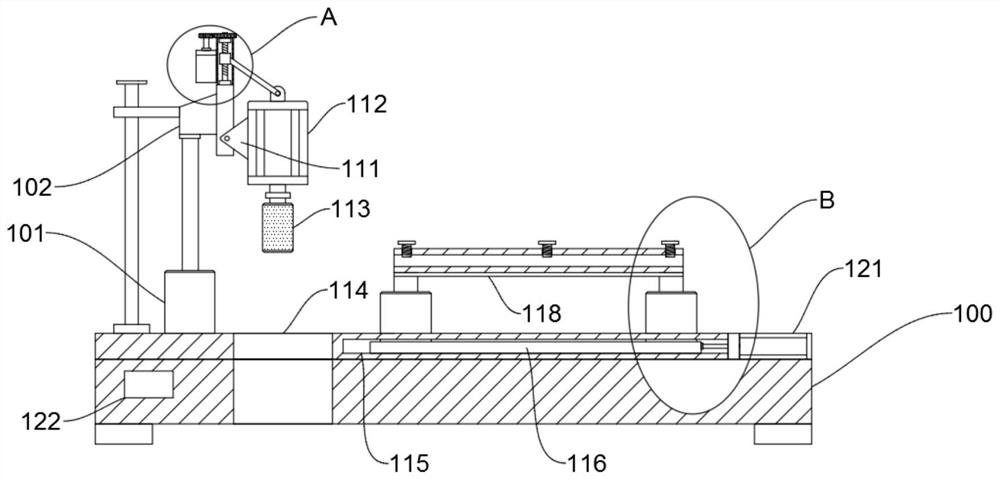

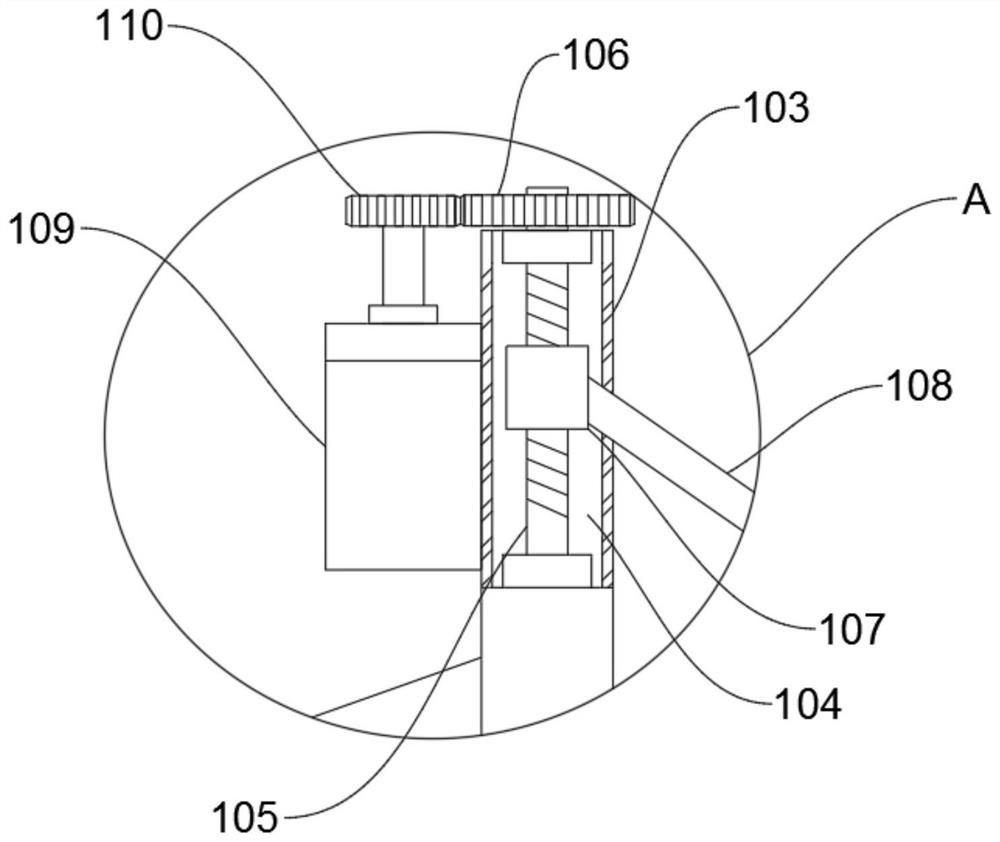

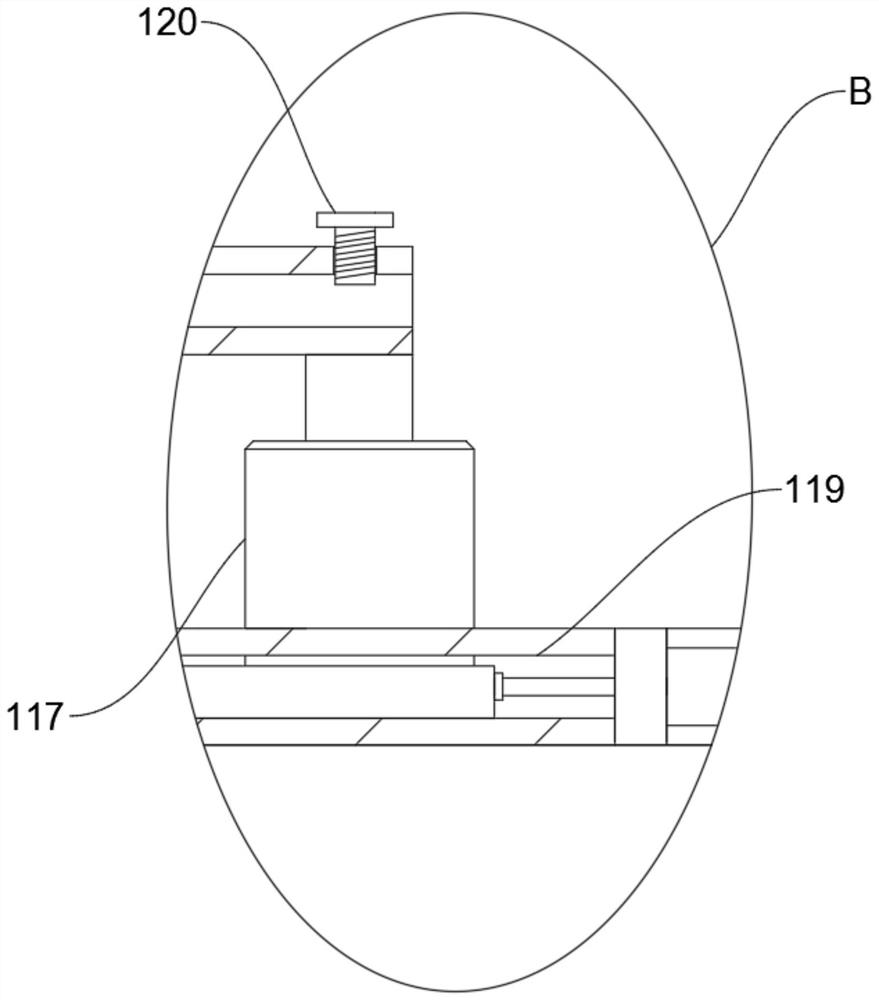

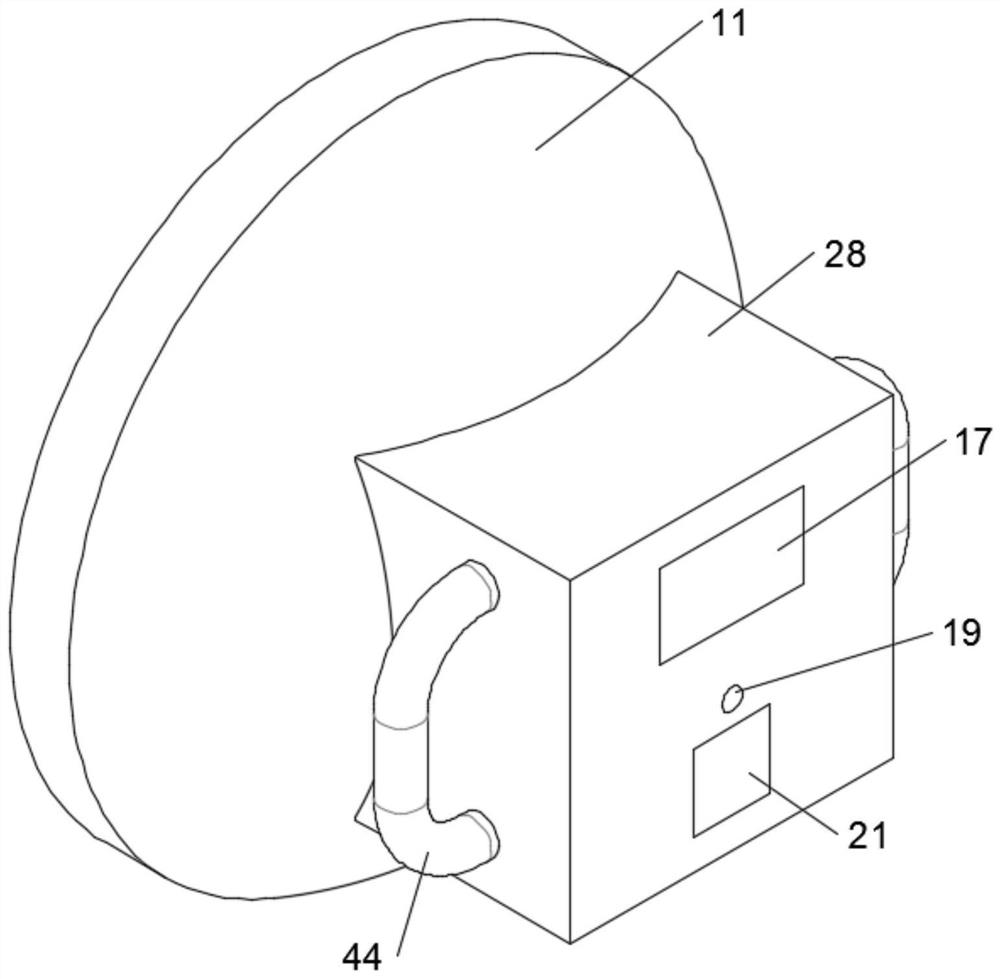

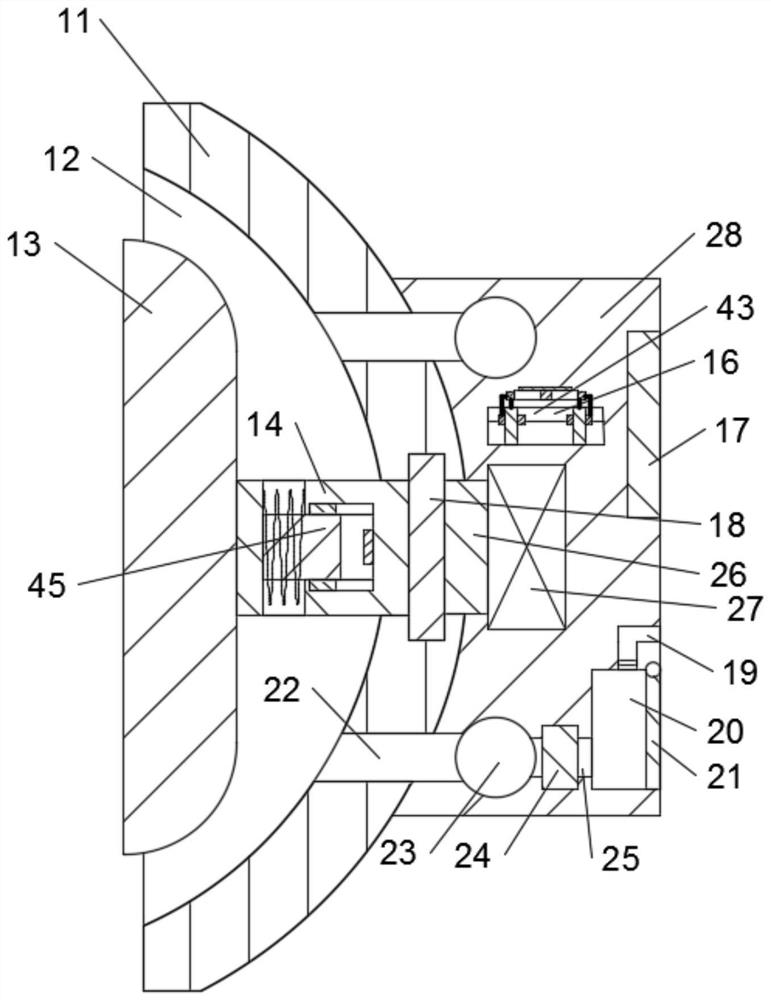

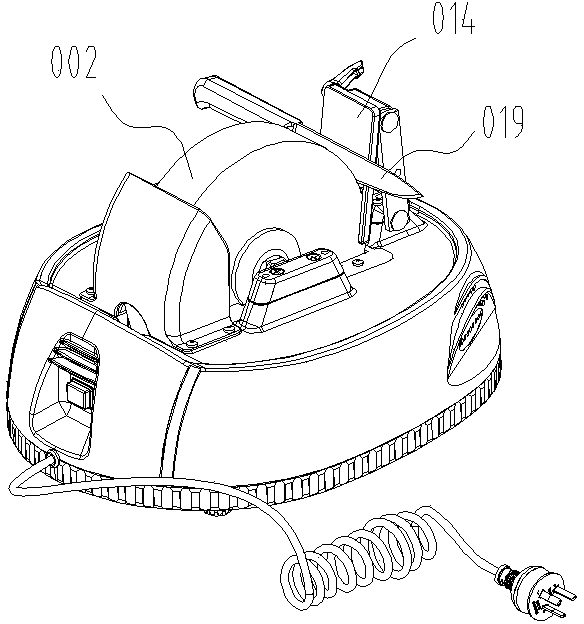

Polishing device for hub processing of new energy automobile

ActiveCN111230710ARealize polishing workRealize polishing and chamfering operationsEdge grinding machinesGrinding carriagesDrive wheelNew energy

The invention discloses a polishing device for hub processing of a new energy automobile, and relates to the technical field of automobile part processing. The polishing device comprises a worktable,a hub top polishing mechanism, a hub side polishing mechanism and a hub limiting rotation mechanism, wherein the hub top polishing mechanism is arranged above the worktable, the hub side polishing mechanism is arranged at the top of the worktable, and the hub limiting rotation mechanism is arranged below the worktable; the hub limiting rotation mechanism comprises a height adjustment assembly, a hub inner circle fixing assembly for clamping a hub inner circle and a rotating assembly for driving the hub to rotate, and a through hole is formed in the top of the worktable so that the hub inner circle fixing assembly can lift and pass through the through hole. According to the invention, the polishing device can clamp the hub inner circle and drive the hub to rotate under the action of the hublimiting rotation mechanism, the angle adjustment of a grinding wheel can be realized through the hub side polishing mechanism, and then polishing chamfering operation on the top surface of the hub is realized.

Owner:山东荣升重型机械股份有限公司

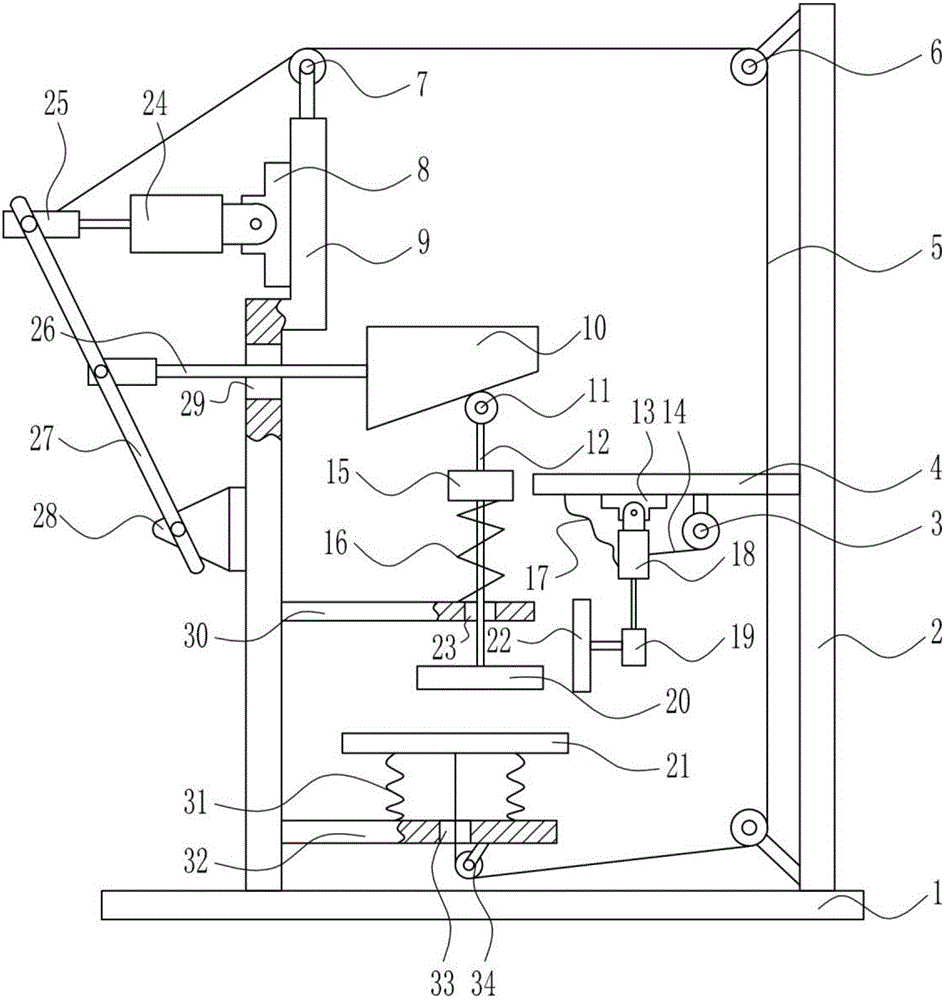

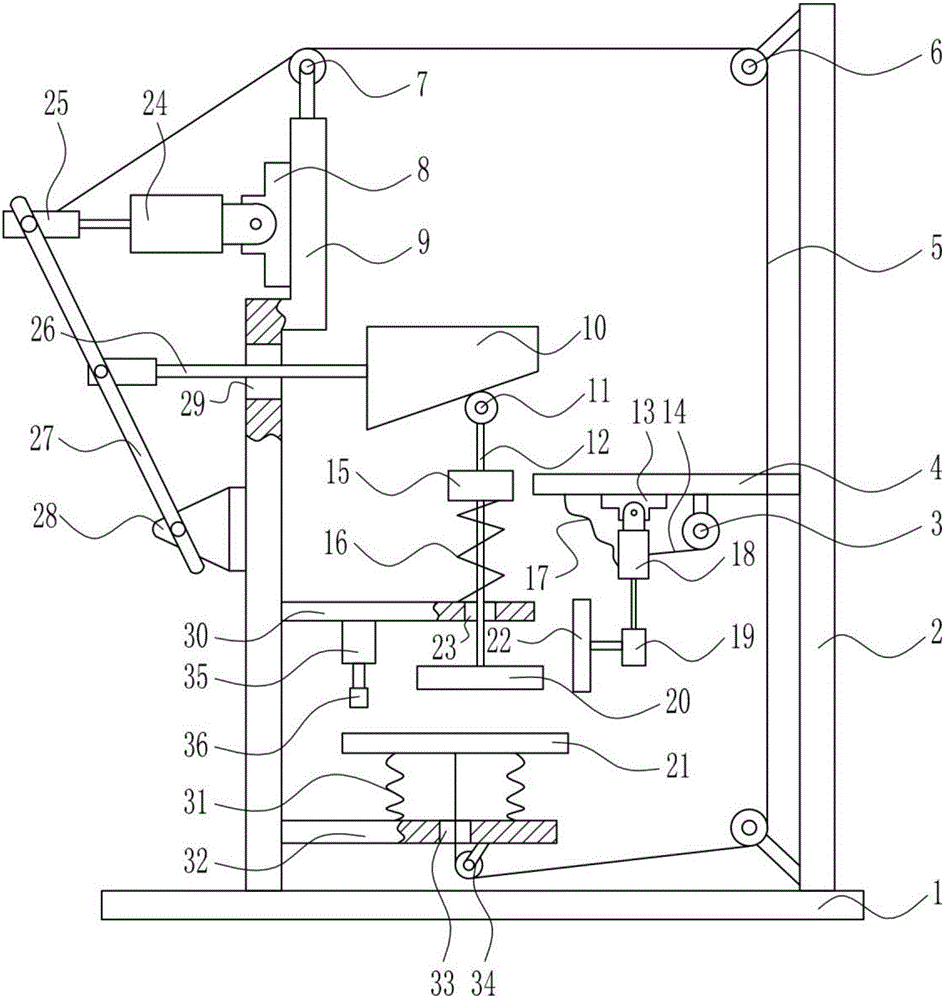

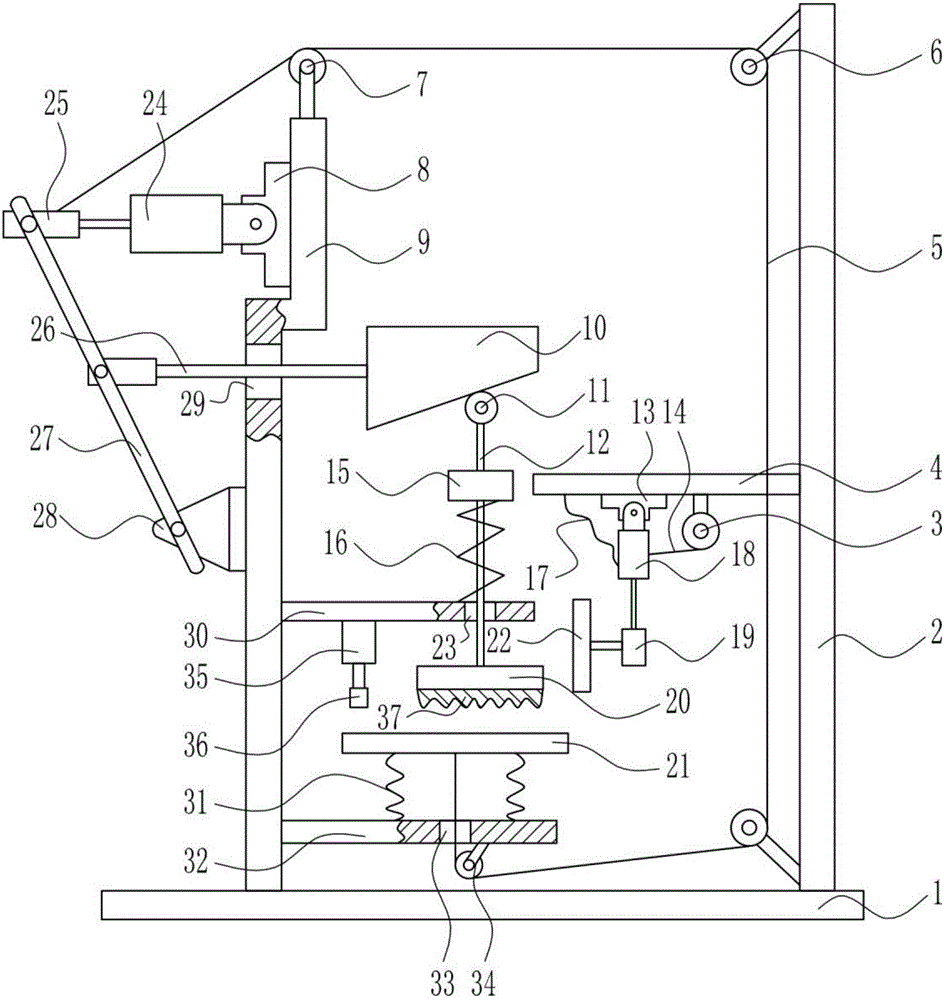

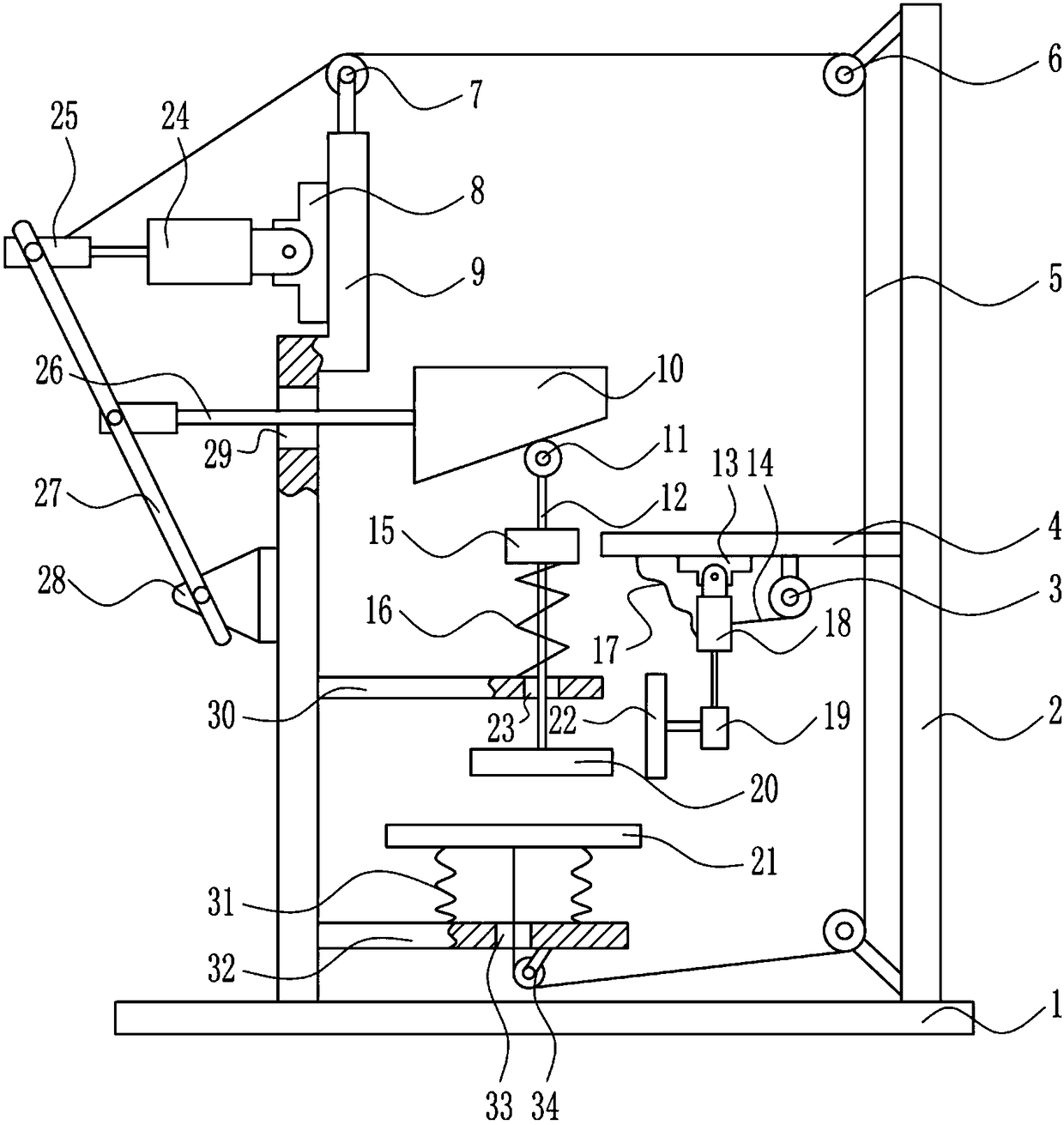

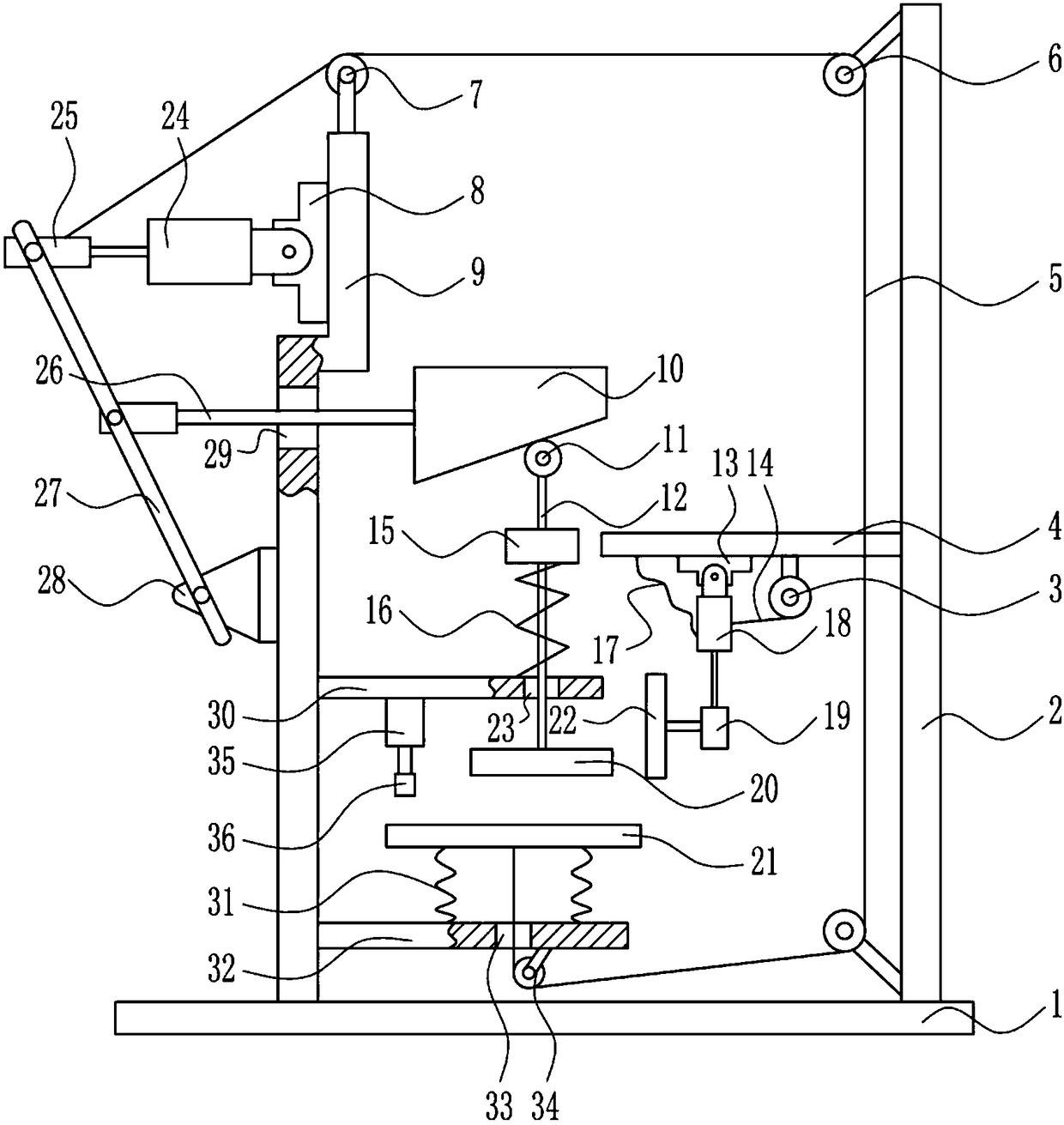

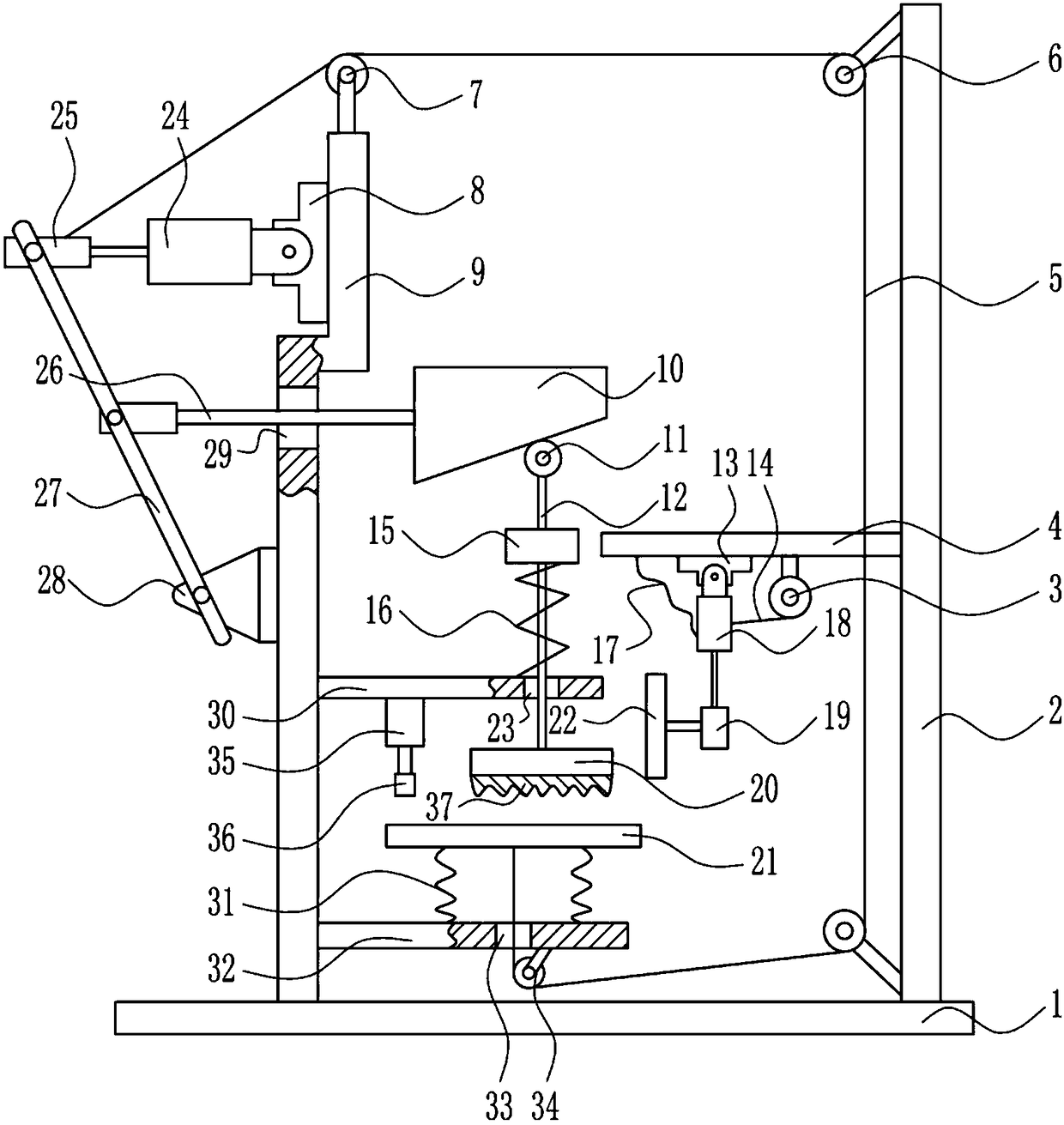

Uniform side and corner polishing device for mosaic tiles

InactiveCN106271953APrevent movementIncrease frictionEdge grinding machinesGrinding carriagesEngineeringLinear actuator

The invention relates to a polishing device, in particular to a uniform side and corner polishing device for mosaic tiles. The technical aim of the uniform side and corner polishing device for the mosaic tiles is to enable side and corner polishing to be uniform. In order to achieve the above technical aim, the uniform side and corner polishing device for the mosaic tiles is provided and comprises a base plate, a right support, an electric wheel, a fixing plate, a first pull wire, a first fixed pulley, a second fixed pulley, a first swing base, a left support, a wedge block, a contact idler wheel, a lifting rod, a second swing base, a second pull wire, a fixing block, a third spring, a first spring, a second linear actuator, a rotation motor, a pressing plate, a containing plate and the like. The left end and the right end of the top of the base plate are provided with the left support and the right support correspondingly. By means of the uniform side and corner polishing device, the effect of being uniform in side and corner polishing is achieved; when the uniform side and corner polishing device is used for side and corner polishing of the mosaic tiles, the polishing angle can be adjusted, and polishing can be more comprehensive; and meanwhile, the manpower for polishing is saved.

Owner:CHONGQING RYAN PAINT CO LTD

Equipment capable of grinding railway accessories in multiple angles

InactiveCN108214204AGood effectReduce physical wasteGrinding drivesGrinding machinesArchitectural engineeringFuselage

The invention discloses equipment capable of grinding railway accessories in multiple angles. The equipment comprises a base plate, the upper surface of the base plate is fixedly connected to the bottom end of a first fixing rod and the bottom end of a second fixed rod, the right side surface of the second fixing rod is fixedly connected to the left side surface of a body of a first motor, and anoutput shaft of the first motor is fixedly connected to the left side surface of a rotating device. According to the equipment capable of grinding the railway accessories in multiple angles, by meansof the cooperation of the first motor, a second motor, a third motor, the rotating device, first electric push rods and second electric push rods, a switch is operated to enable the first motor to rotate, when a placing plate corresponds to a grinding block, the railway accessories can be ground, then the grinding block can grind the railway accessories in multiple angles, so that people do not need to manually adjust the positions of the railway accessories, the waste of physical power of people can be reduced, the effect of grinding the railway accessories can be better, and therefore the working efficiency of people can be guaranteed.

Owner:李理

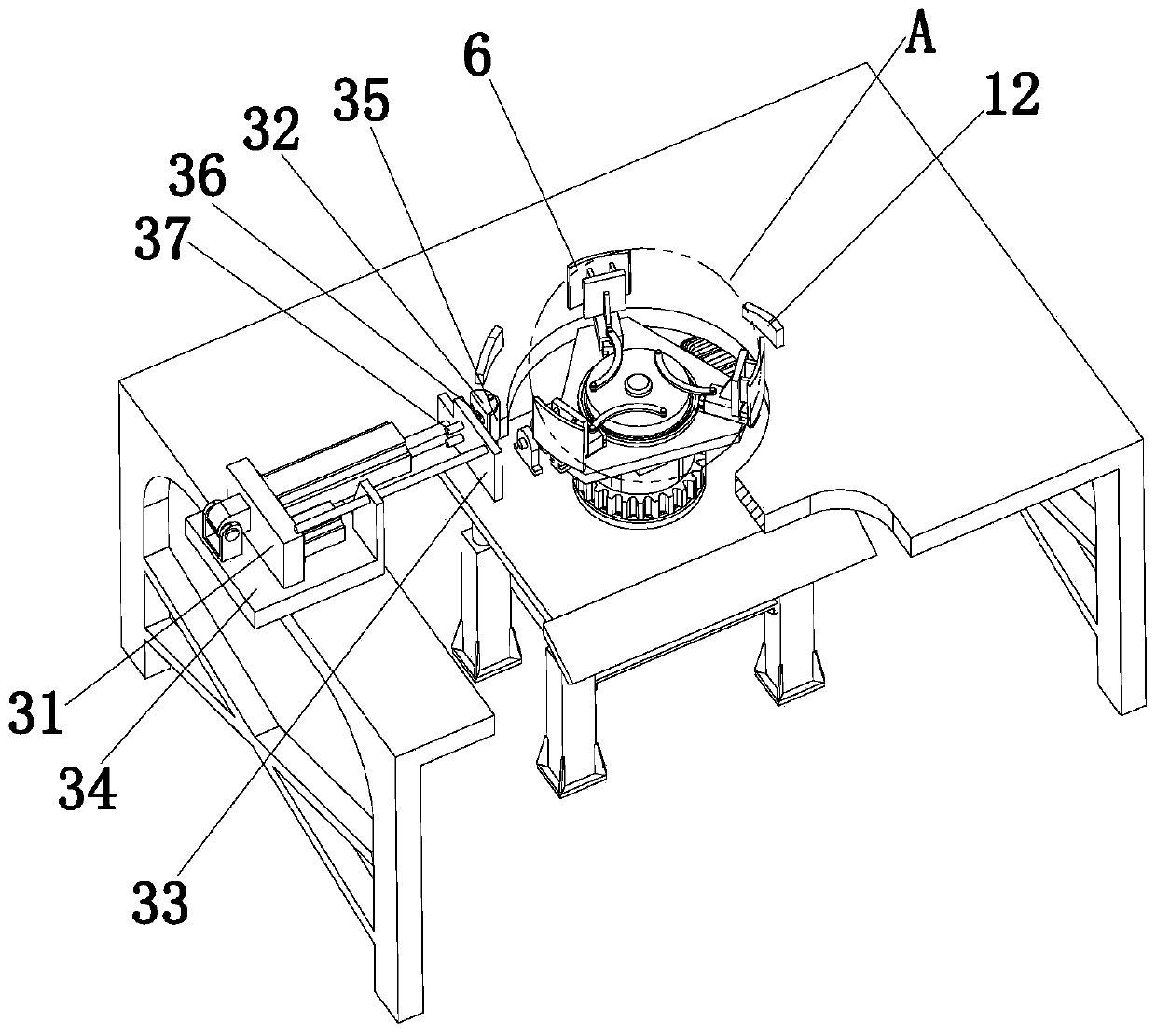

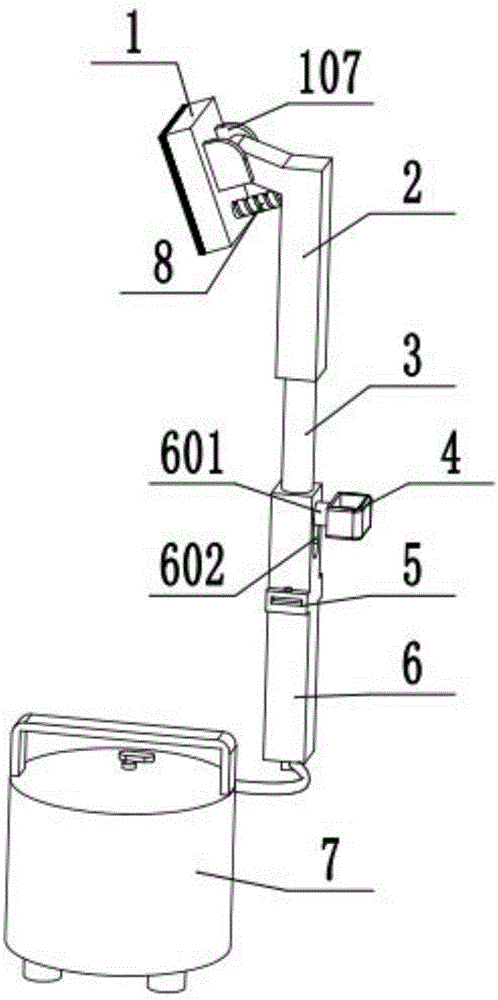

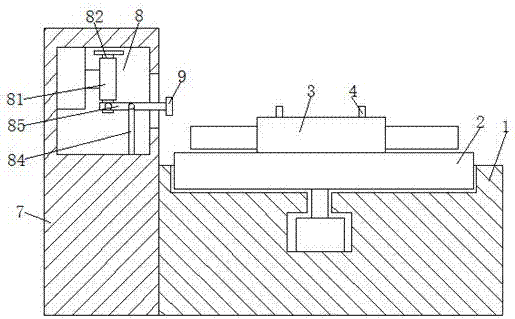

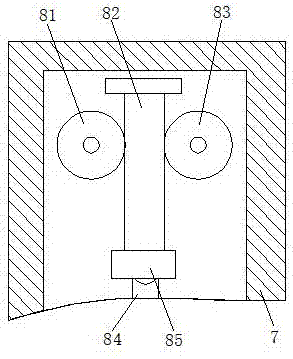

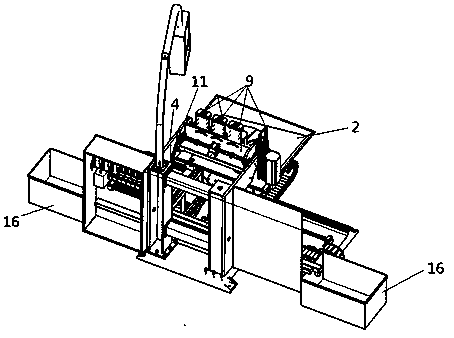

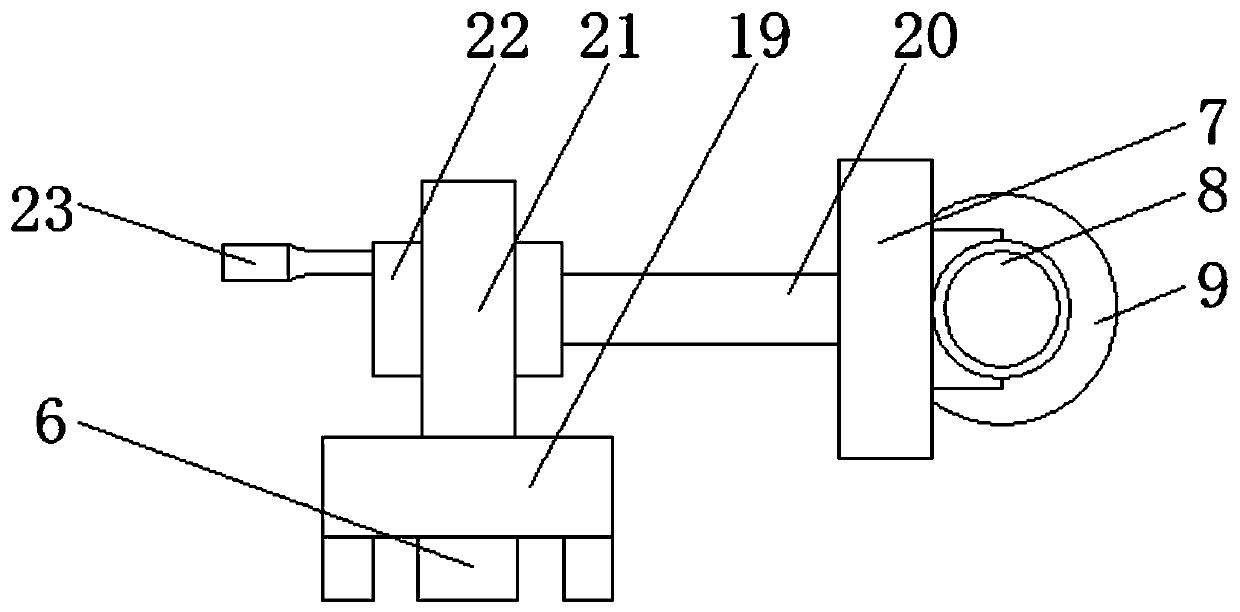

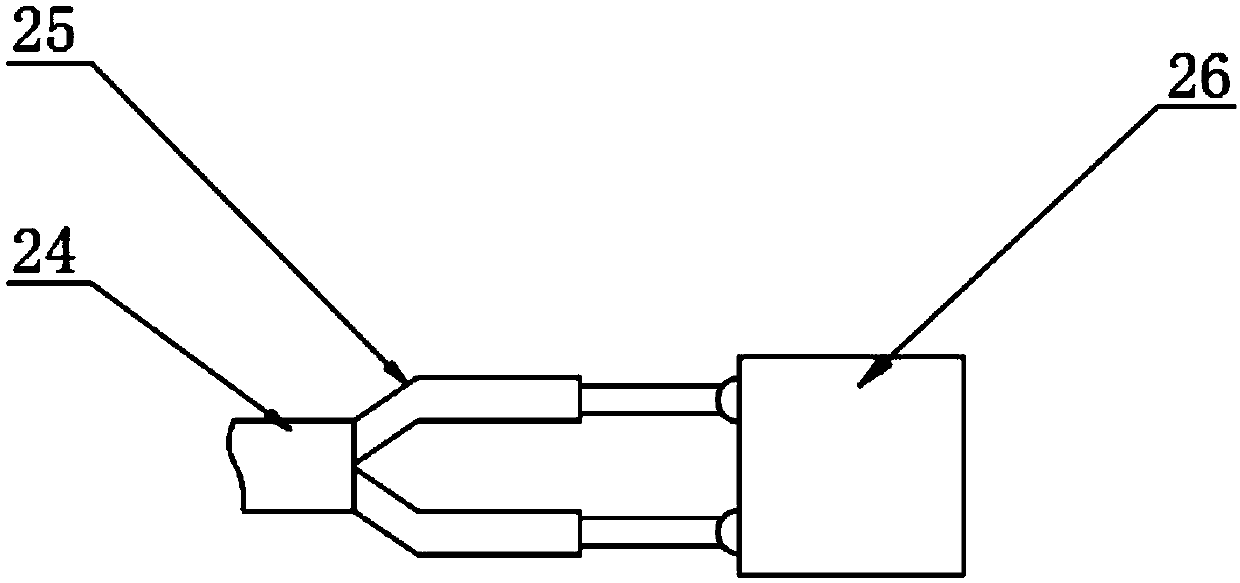

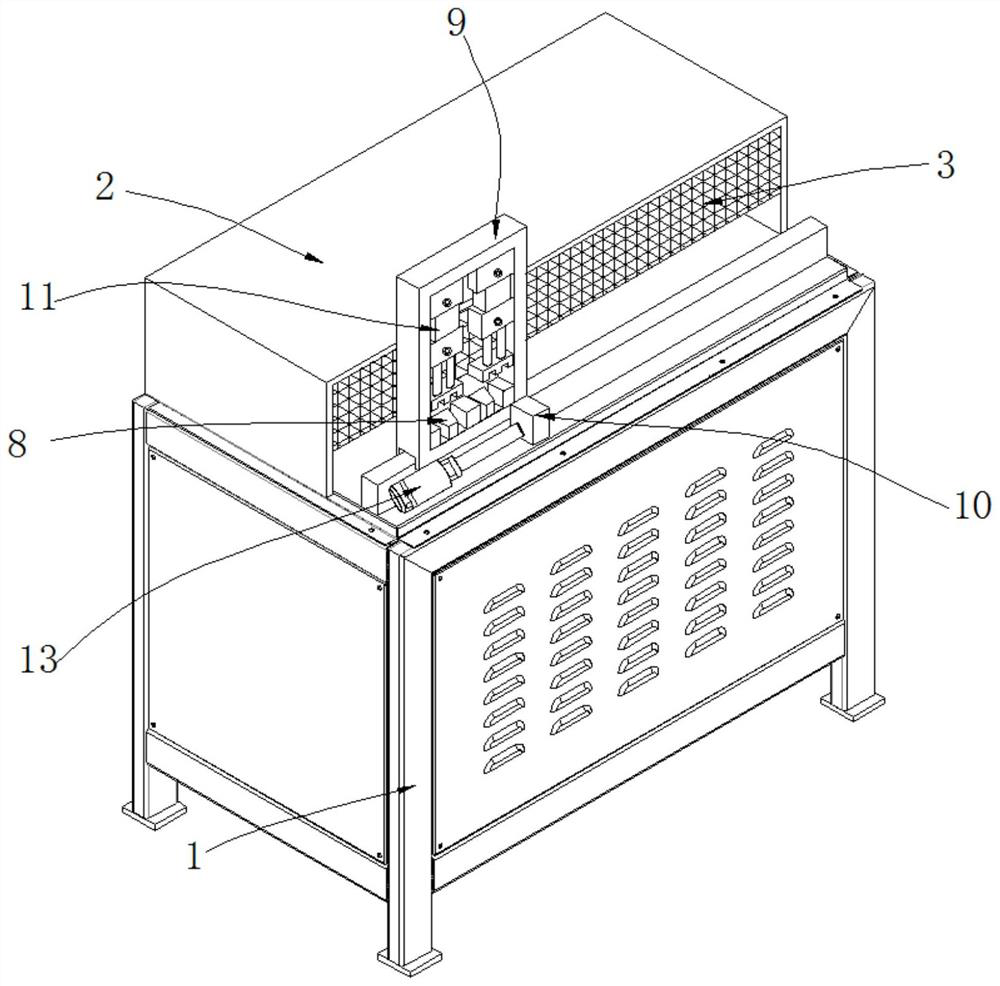

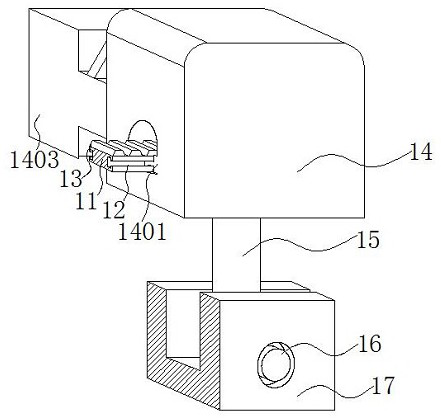

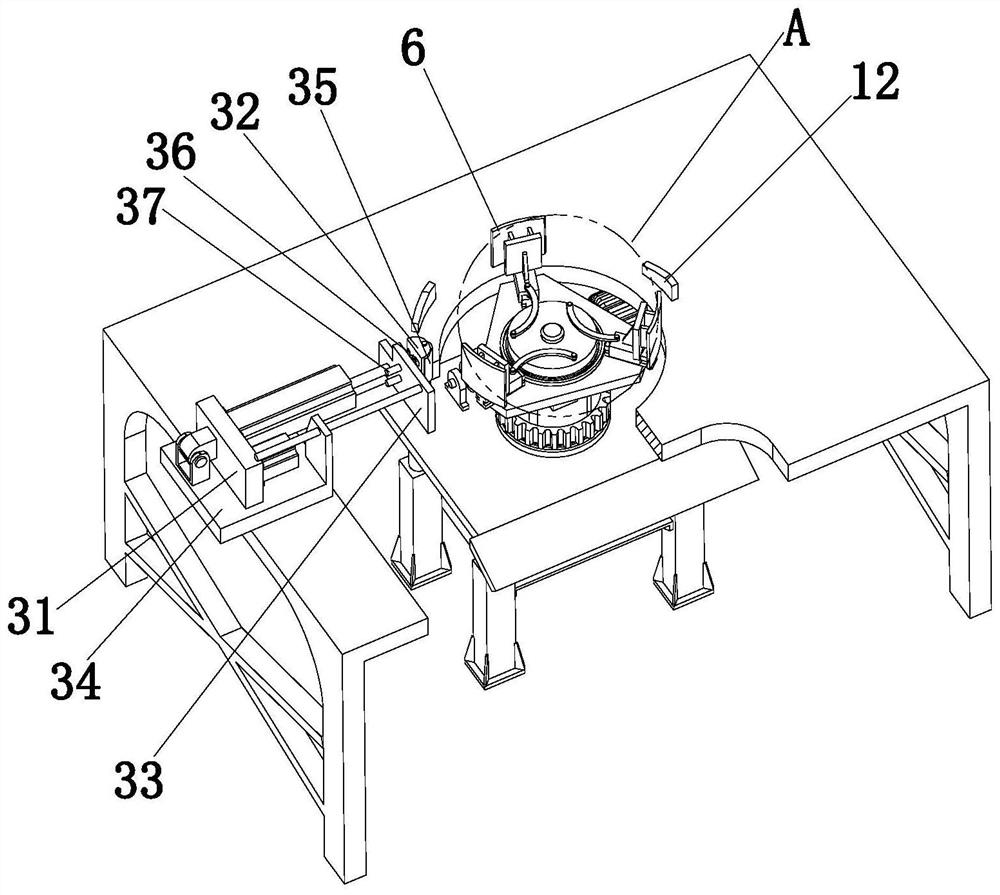

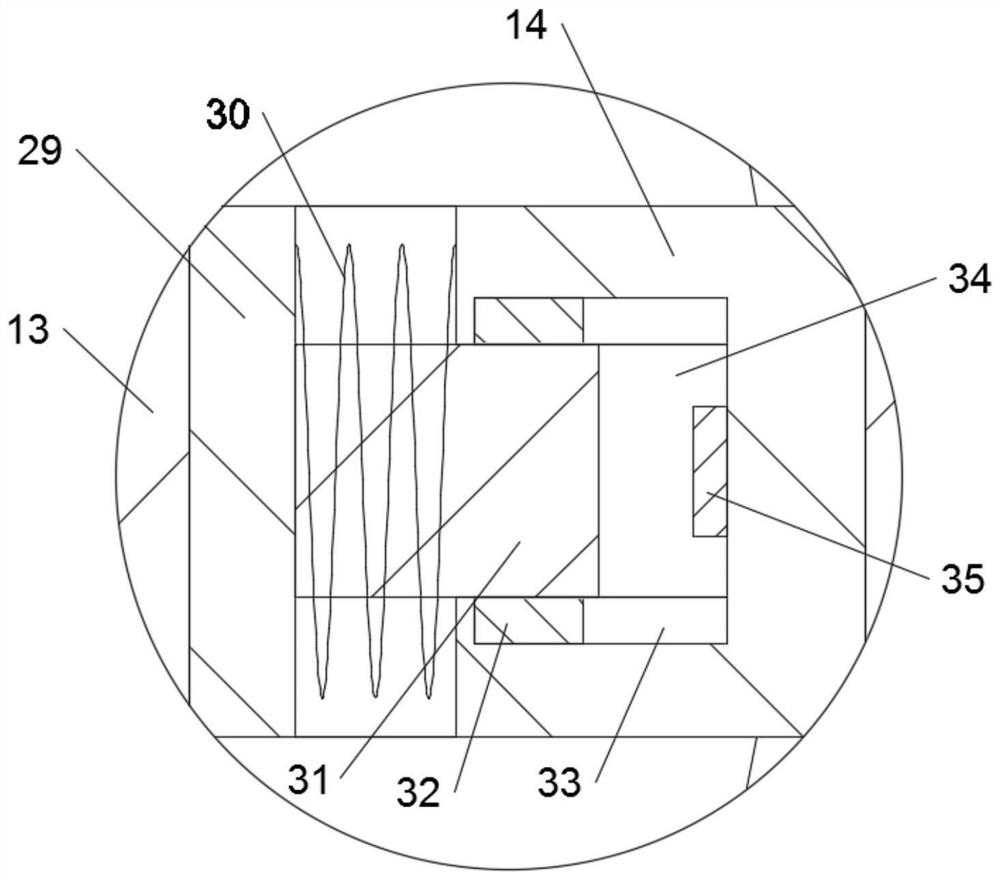

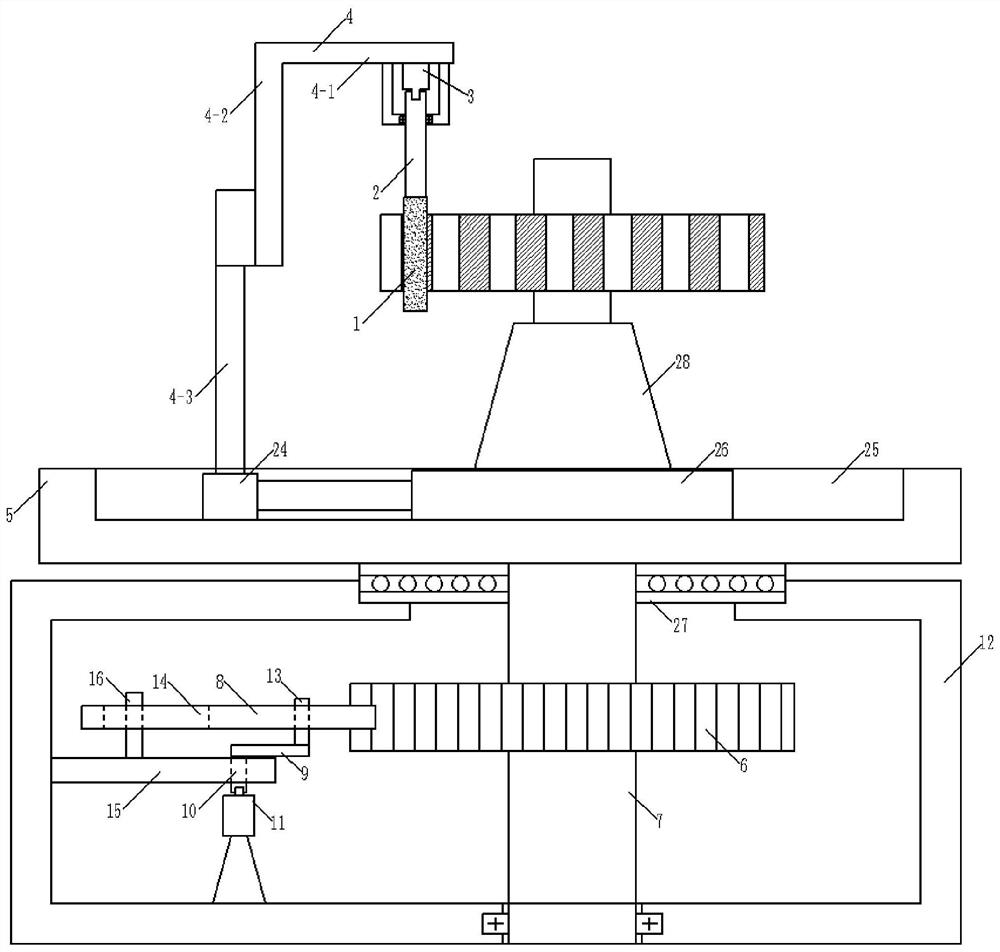

Optical lens automatic milling and grinding machine and automatic milling and grinding method thereof

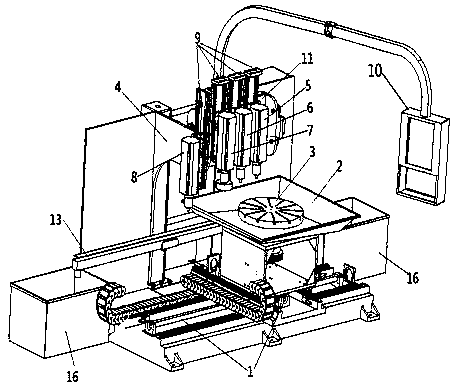

ActiveCN108127512ATo achieve the effect of automatic deliveryAchieve the effect of automatic safe grindingOptical surface grinding machinesGrinding drivesControl systemEngineering

The invention relates to an optical lens automatic milling and grinding machine and an automatic milling and grinding method thereof, and in particular to the technical field of optical lens milling and grinding. The optical lens automatic milling and grinding machine comprises a milling and grinding machine box, a controller, an automatic feeding mechanism, a feeding mechanism, a machining mechanism, an automatic material supplying device, a vacuum control system, a first air cylinder, a second air cylinder, a third air cylinder, a fourth air cylinder, a fifth air cylinder, a first material taking arm, a second material taking arm, a third material taking arm, a fourth material taking arm, a first vacuum cup, a second vacuum cup, a third vacuum cup, a fourth vacuum cup, a fifth vacuum cup, a first positioning device, a second positioning device, a first rotating device, a second rotating device, a digital readout dial indicator, a material taking swing arm, a feeding arm, a first piston rod, a second piston rod and a buffering device. The optical lens automatic milling and grinding machine adopts a full-automatic operation mode, solves the problem that operation needs to be conducted depending on manpower all the time in the prior art, and achieves the effects that the manpower cost is lowered, and the equipment efficiency is improved.

Owner:AZURE PHOTONICS

Building wall polishing device

InactiveCN107520702AAvoid interferenceCooperate wellPlane surface grinding machinesGrinding/polishing safety devicesPolish teethArchitectural engineering

The invention discloses a building wall polishing device. The building wall polishing device consists of a polishing device, a dust sucking device, a support rod, an auxiliary belt and an operation handle; the polishing device consists of a polishing box, an extension cover and a polishing belt; the polishing belt is rotationally connected with the polishing box through a bearing; polishing teeth are arranged on the polishing belt; the extension cover fixedly connected is arranged at an opening end of the polishing box; a dust sucking hole is formed in a receiving box, and is provided with a dust sucking pipe; a connecting plate is arranged at the back end of the polishing box, and is rotationally connected with the support rod; and the support rod consists of an upper support rod, a connecting column and a lower support rod. The support rod can be fixed on a body through cooperation of an insertion port and an insertion head to share the weight of an arm, so that the operation is easier; and the building wall polishing device can realize adjustment of the polishing angle and polishing of a top wall.

Owner:WUHAN YIWEIDENG TECH DEV

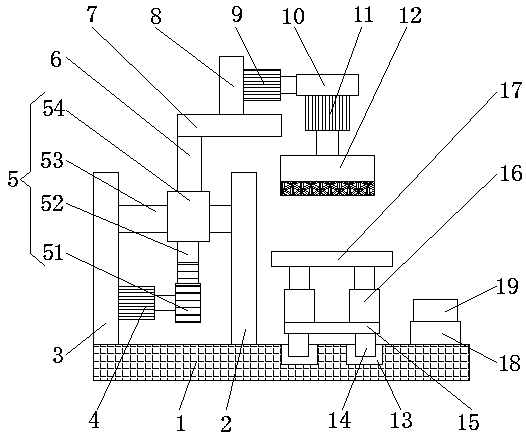

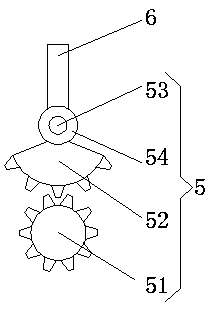

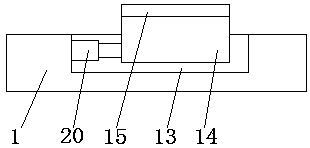

Adjustable glass edging device

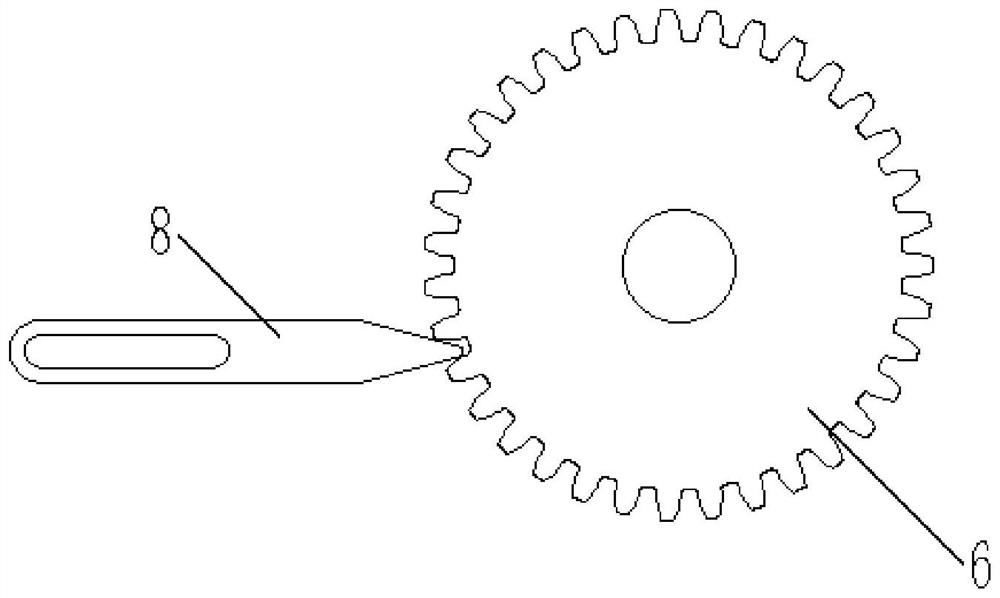

PendingCN107263245AGuaranteed stabilityAdjustable angleEdge grinding machinesGrinding feedersGear drivePolishing

The invention discloses an adjustable glass edging device which comprises a working table. An installing plate is arranged on one side of the working table, two baffles are arranged on the side, far away from the working table, of the installing plate, two thread pressing rods are connected to the two baffles through threaded holes, a pressing plate is arranged at the ends, close to the installing plate, of the thread pressing rods, a supporting base is arranged on one side of the working table, and an adjusting device is arranged inside the supporting base; and a cavity matched with the adjusting device is arranged in the supporting base, the adjusting device comprises a transmission gear, a transmission rack, a balance gear, a supporting rod and an adjusting rod, and the transmission gear is arranged inside the supporting base. The adjustable glass edging device is simple in stricture and convenient to operate, the polishing angle of a polishing block can be adjusted according to production requirements quickly and conveniently, and the applicability is high; and meanwhile, installation and fixing are reliable, direct polishing and edge alignment can be carried out after rotary operation, the number of installing times is reduced, the time is saved, and the polishing efficiency is improved.

Owner:盐城市宁润玻璃制品有限公司

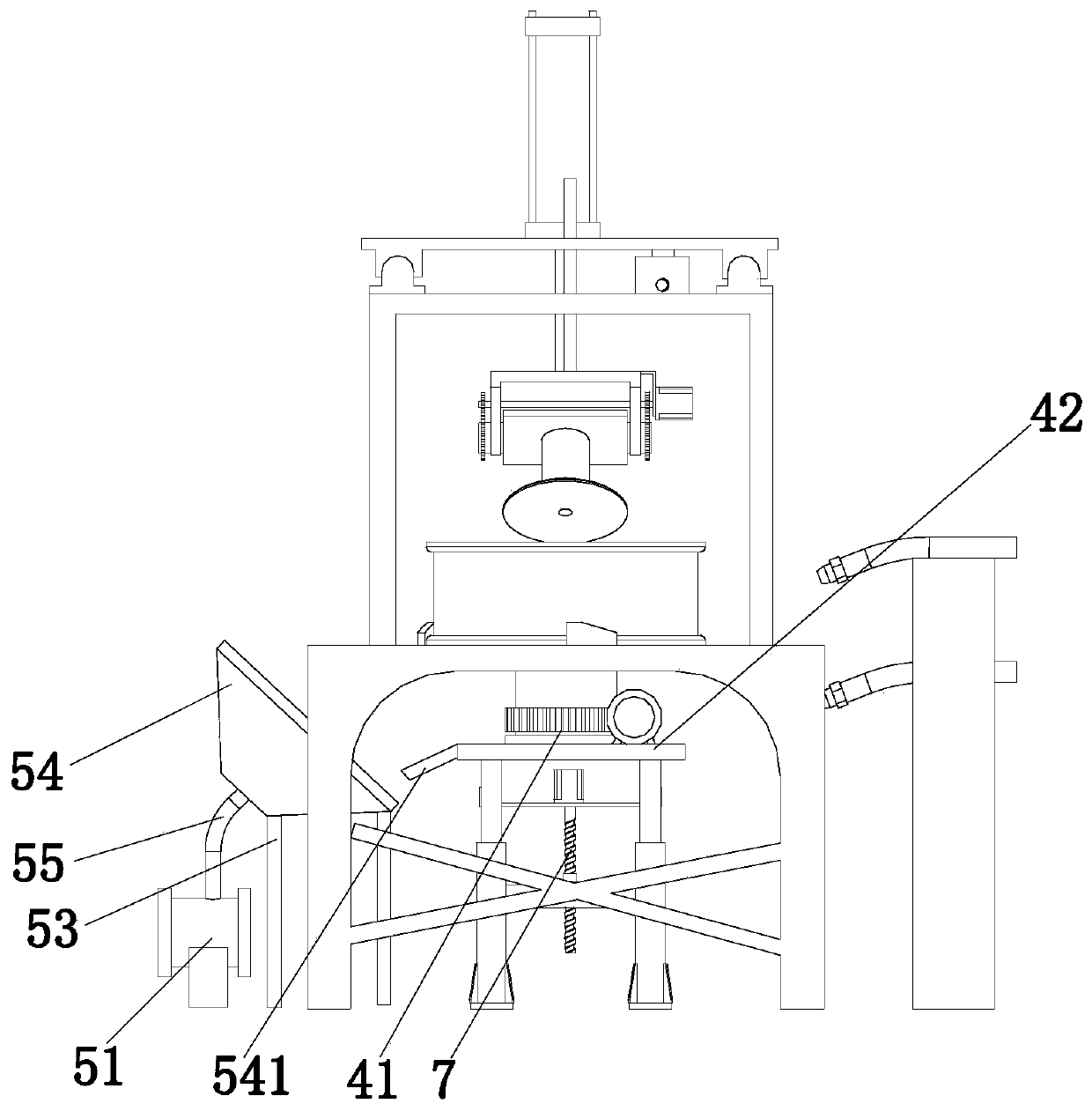

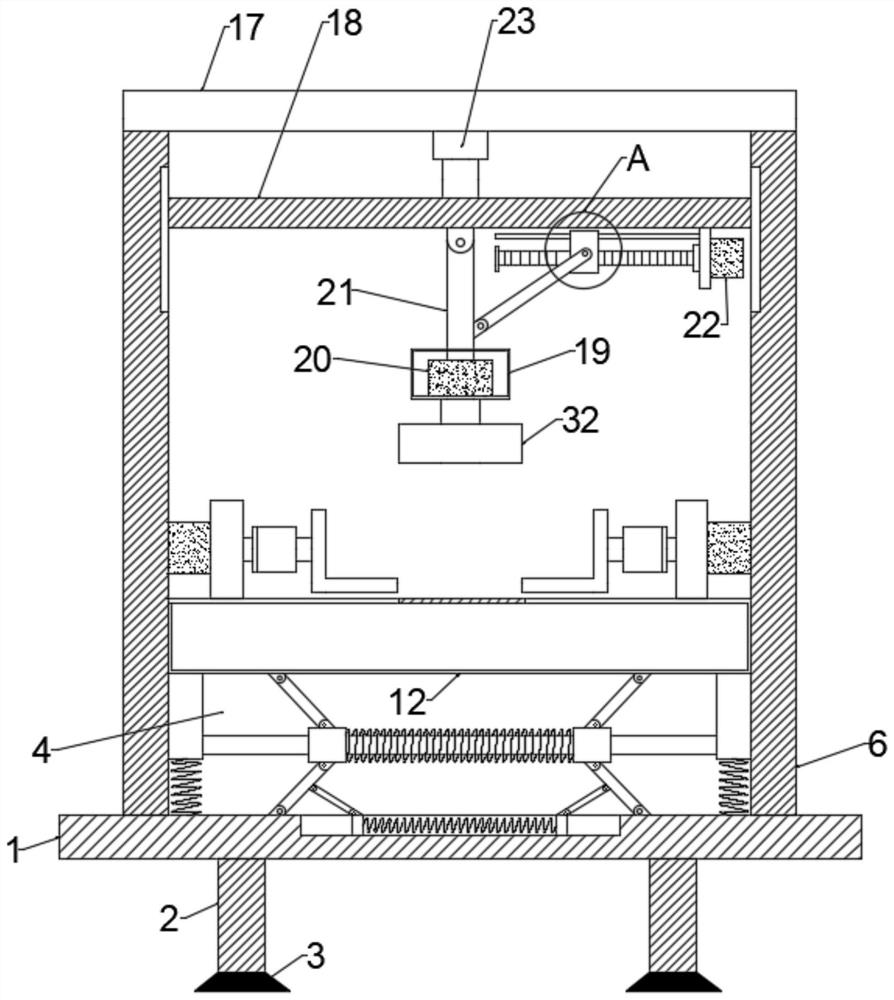

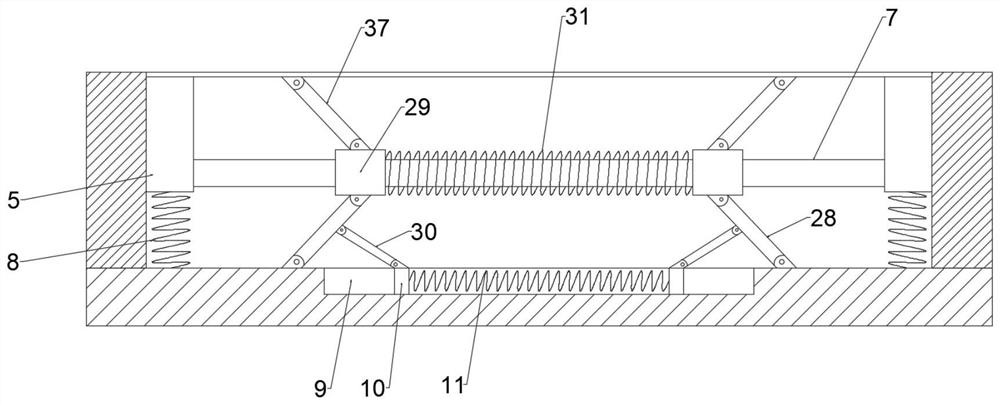

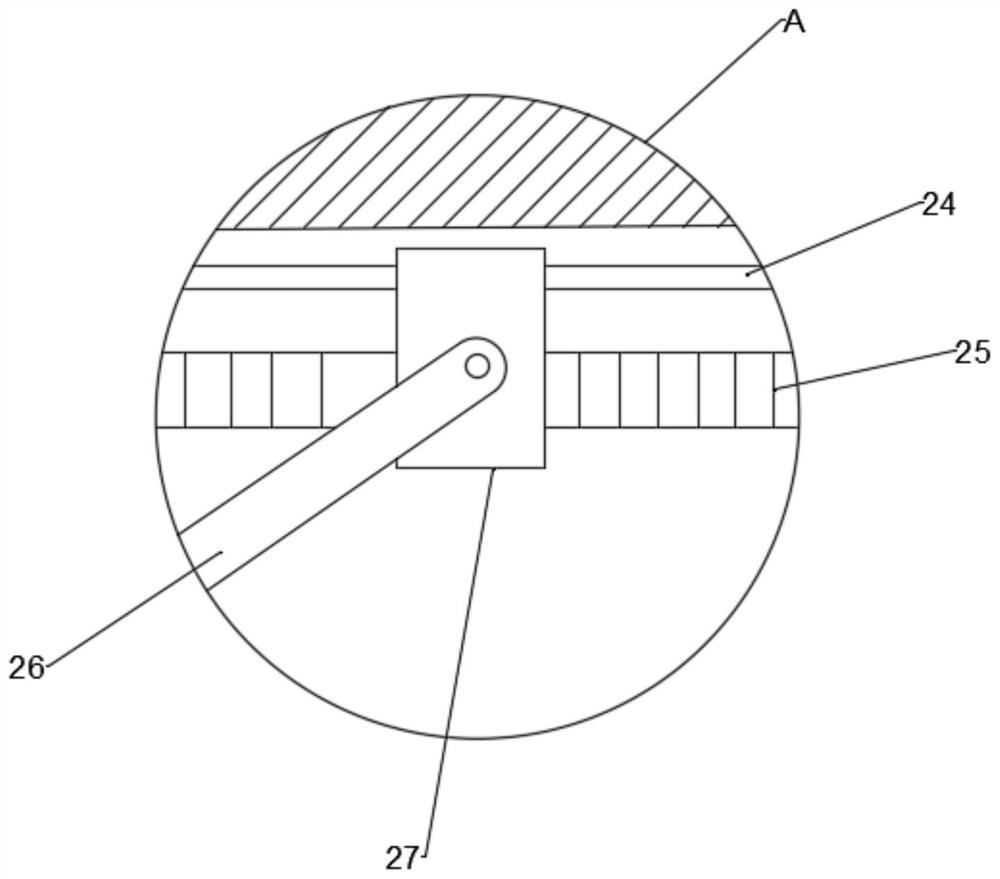

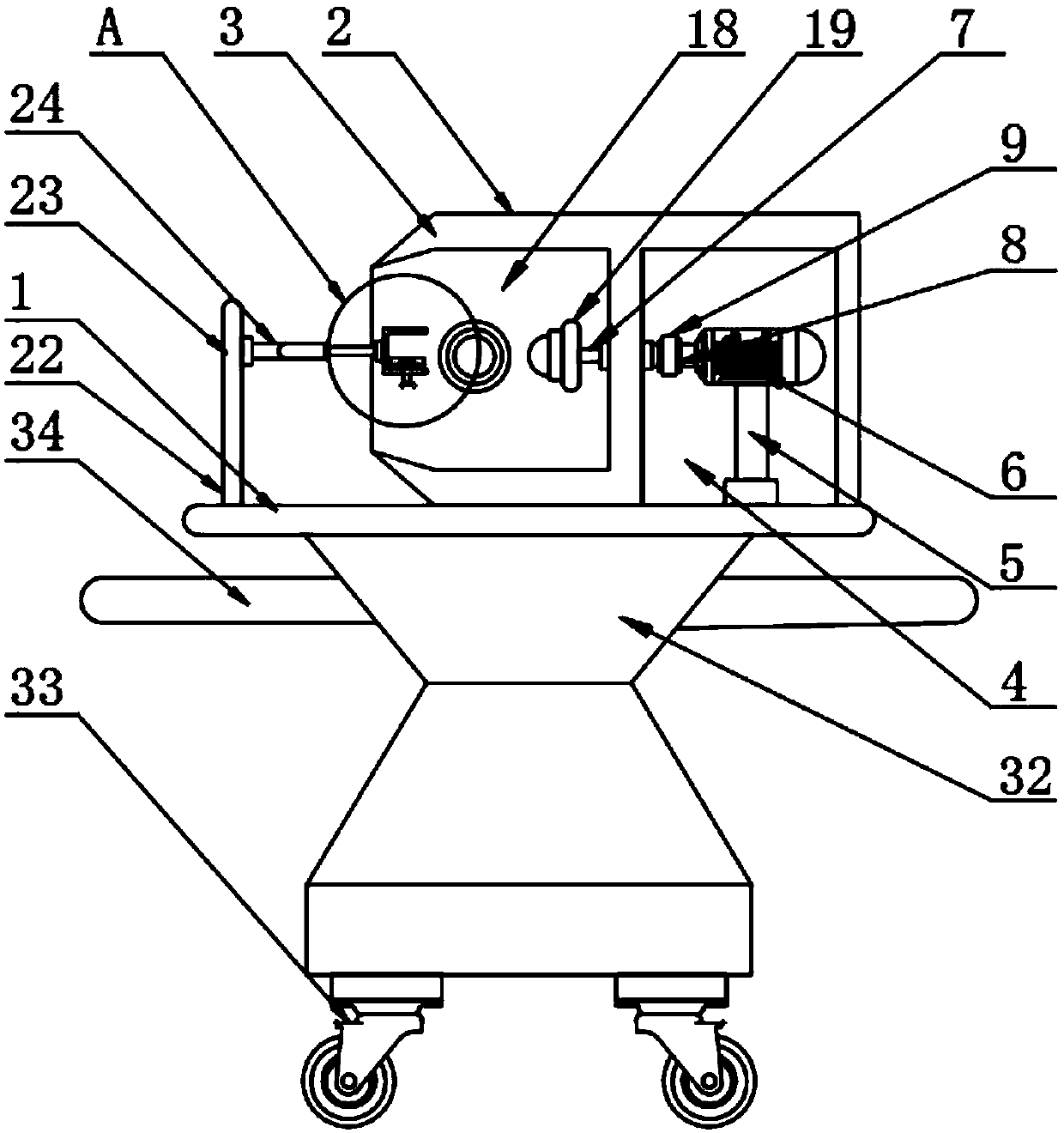

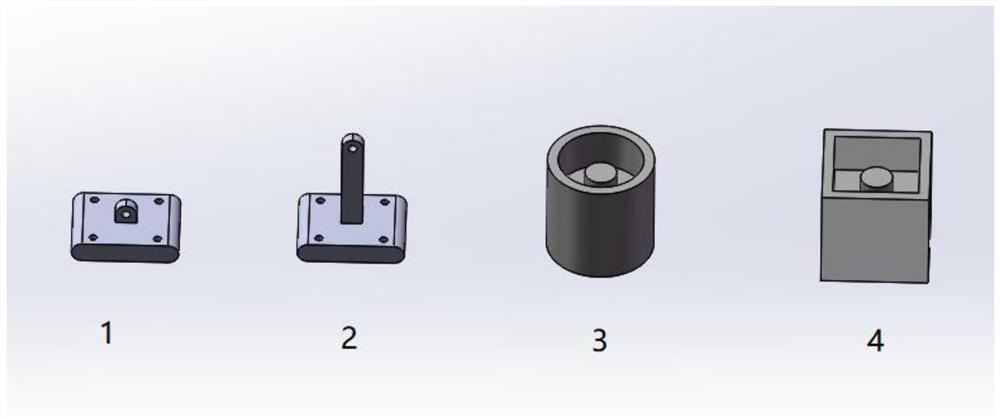

Sports equipment casting machining device

PendingCN113084633AAdjust the grinding angleImprove grinding effectEdge grinding machinesGrinding carriagesPolishingSports equipment

The invention discloses a sports equipment casting machining device. The device comprises a base, wherein supporting columns are fixedly connected to the left side and the right side of the top end of the base correspondingly. Firstly, a casting is fixed by arranging an air cylinder and a clamp, and then a second motor, a threaded rod, a threaded block and a first connecting rod are arranged to drive a movable rod to move left and right, so that the polishing angle of a polishing head can be adjusted, the casting is polished in all directions, the polishing effect is better, a third motor is arranged to drive the clamp to rotate so as to turn over and polish the casting, manpower is greatly saved, and use is convenient. By arranging a cooling water tank and a spray head, cooling water can be sprayed to the casting, the casting can be cooled, chippings on the surface of the casting can be washed away, the machining quality is guaranteed, by arranging a damping assembly, damping can be conducted on the device, the mechanical loss of the device is reduced, the service life of the device is prolonged, and the device is novel in structure, complete in function, convenient to use and high in practicability.

Owner:连云港超越重型传动件有限公司

Full automatic stone slab edger unit

A fully automatic stone slab edger unit comprises a frame; the frame is provided with a milling machine and a clamp drive mechanism; the milling machine is arranged under the clamp drive mechanism; the clamp drive mechanism comprises two rows of gripping rolls which are vertically arranged, wherein, a bracket of the first row of the gripping rolls is arranged at the frame; the second row of the gripping rolls are rubber pressure rolls; a bracket of each rubber pressure roller is movably arranged at the frame in the manner of a cross slip; a bracket corresponding to each rubber pressure roll is provided with a transverse thrust cylinder; a piston rod of the transverse thrust cylinder is fixedly connected with the bracket of the rubber pressure rolls. The fully automatic stone slab edger unit of the invention can vertically clamp a stone slab and drive the stone slab to move back and forth, has firm gripping, and causes the stone slab to move stably.

Owner:李 新杰

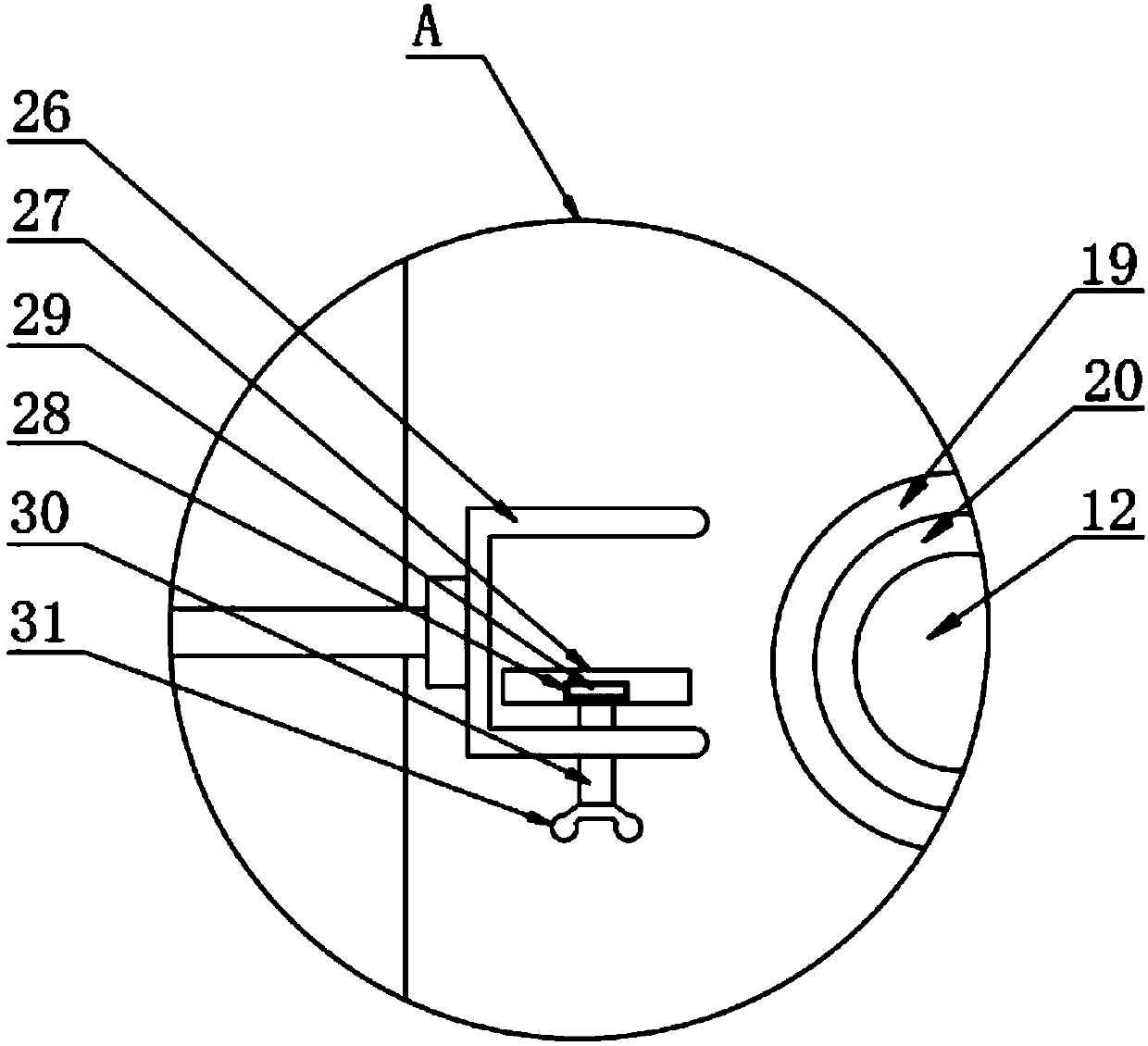

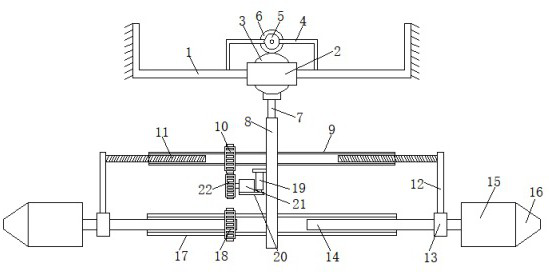

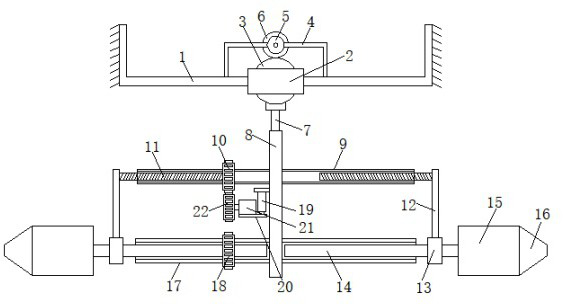

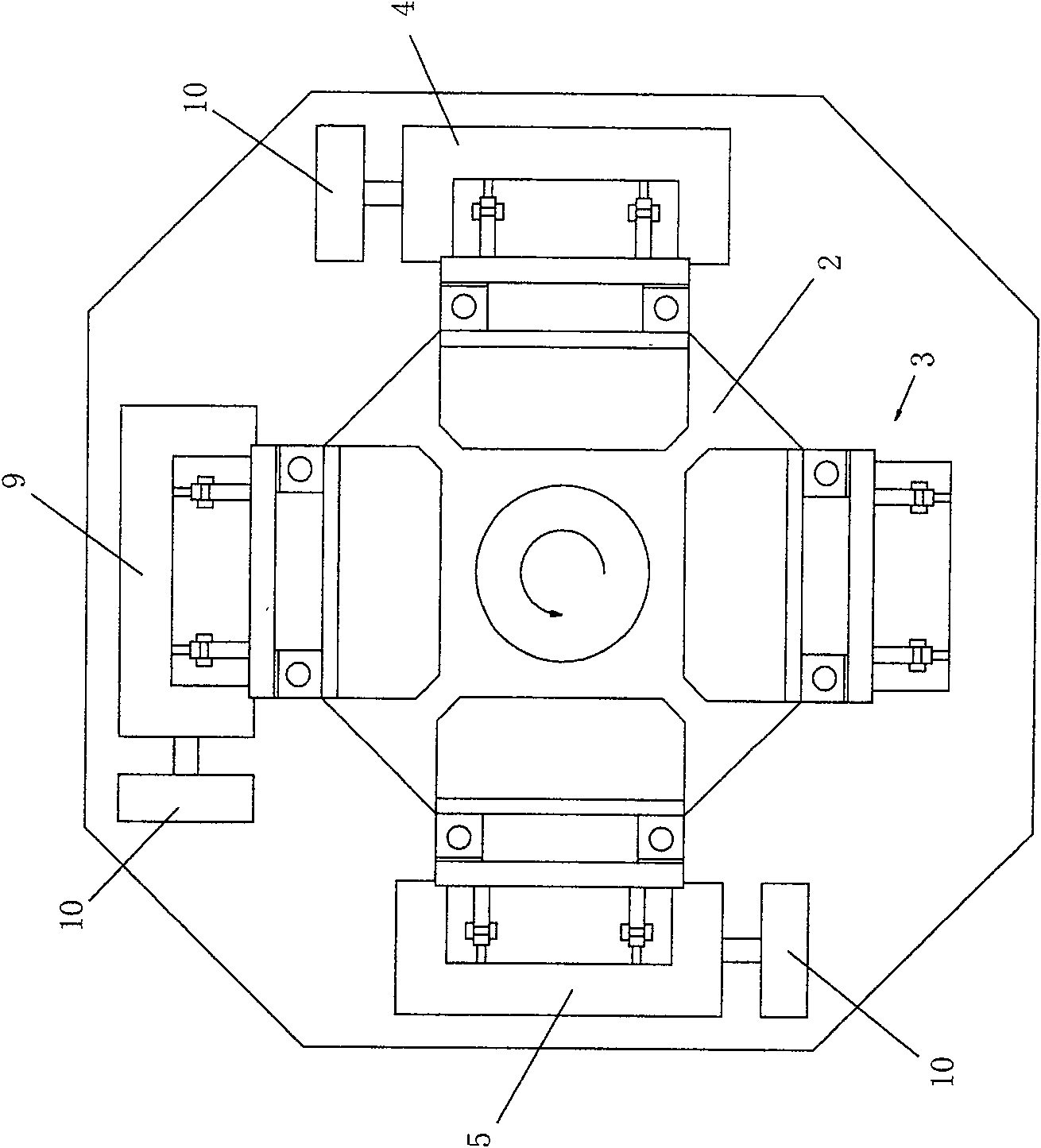

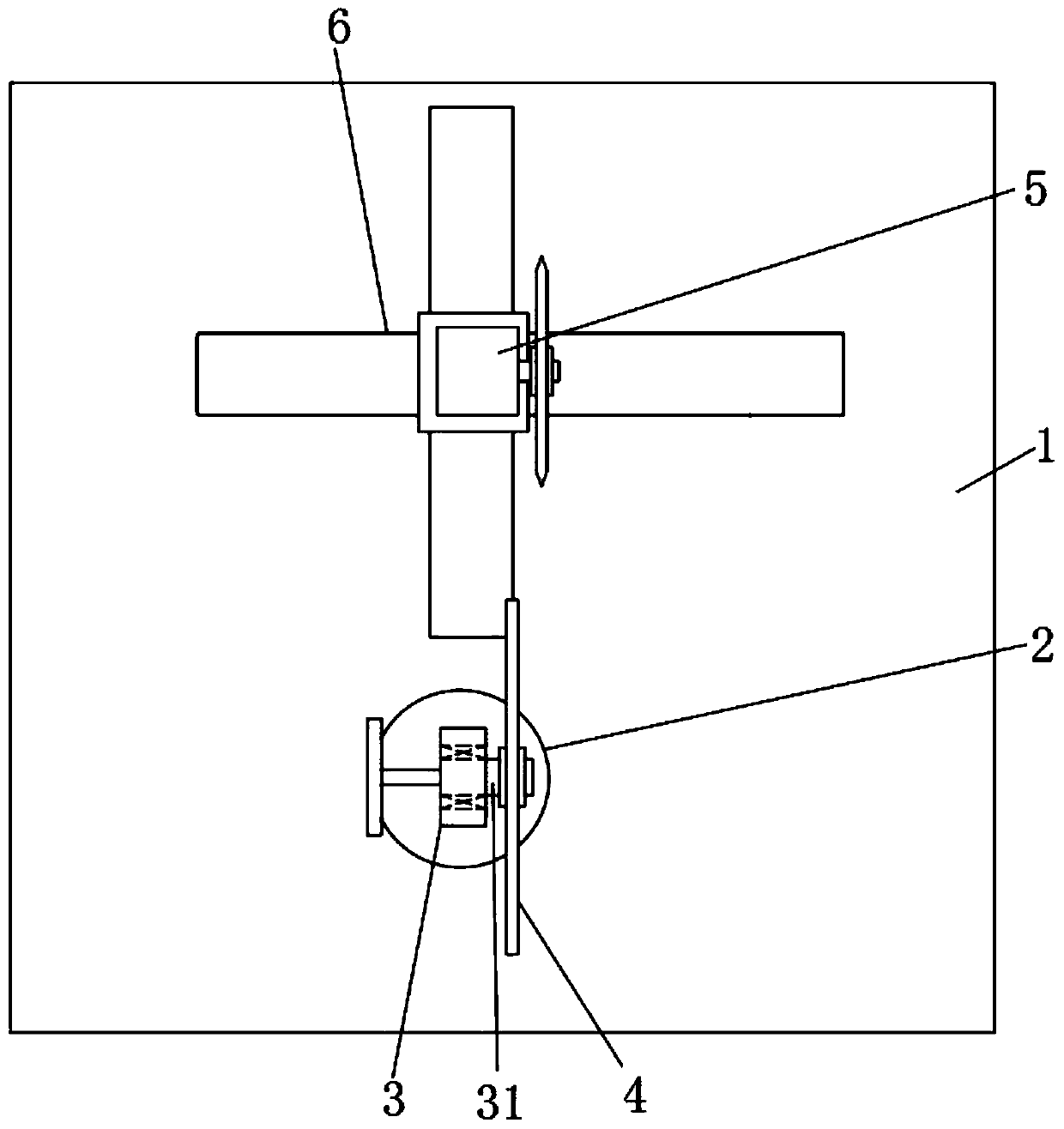

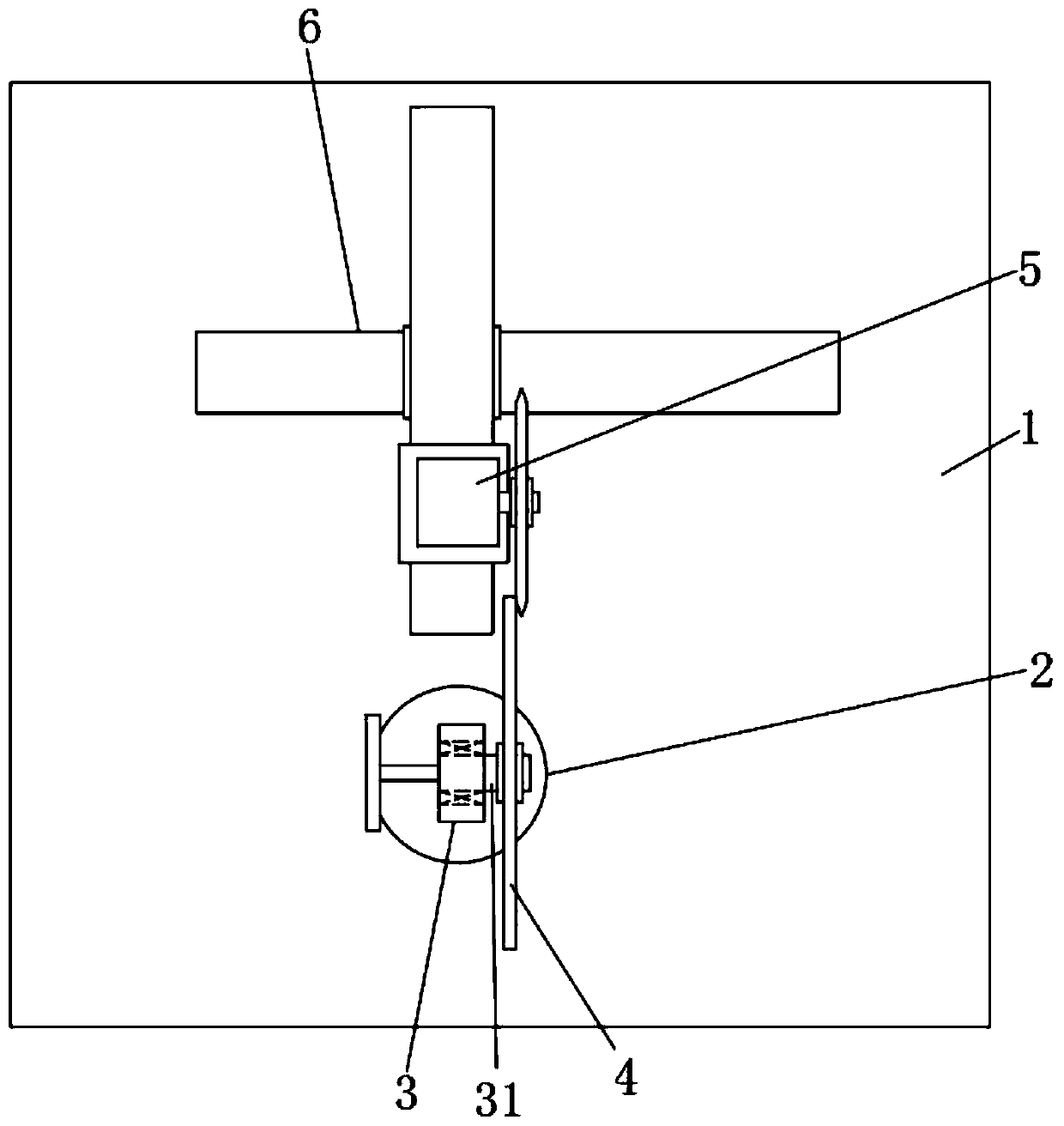

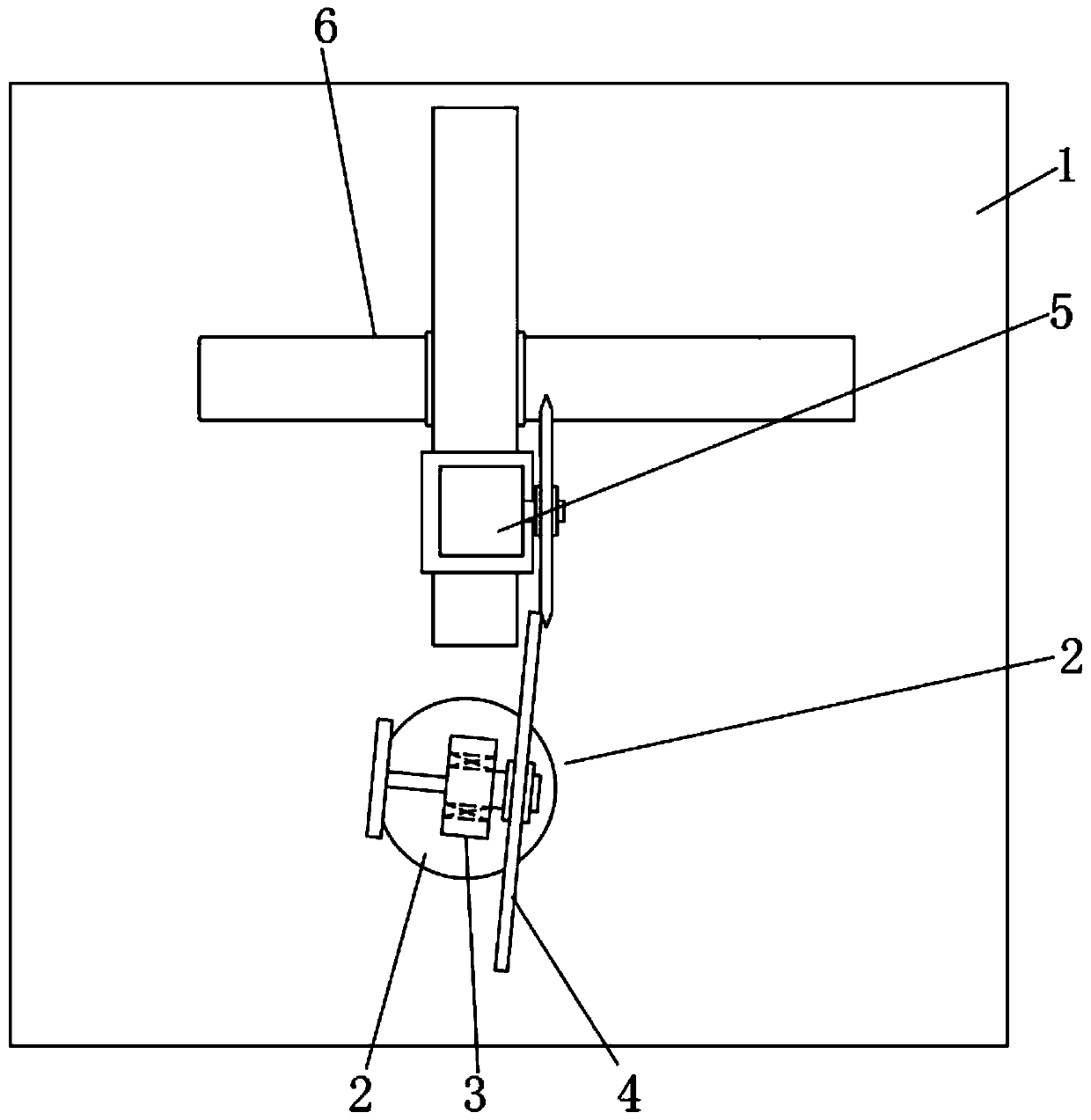

Special-shaped glass processing center

PendingCN110227980AAdjust the grinding angleRealize surface grindingEdge grinding machinesGrinding machine componentsNumerical controlReciprocating motion

The invention belongs to the technical field of special-shaped glass processing, in particular to a special-shaped glass processing center which comprises a numerical control cross-shaped sliding table, a water tray, a rotary fixing table, and an edge polishing mechanism distributed on the circumference of the rotary fixing table. The edge polishing mechanism is fixed onto a rack and comprises a deep grinding forming motor, a rough polishing motor, a fine polishing motor and a periphery grinding motor; the deep grinding forming motor, the rough polishing motor, the fine polishing motor and theperiphery grinding motor are fixed onto respectively corresponding electric sliding tables; first power sources for driving the electric sliding tables to move in a reciprocating way are arranged onthe electric sliding tables; the deep grinding forming motor, the rough polishing motor and the fine polishing motor are fixed onto installation plates; the installation plates are hinged and fixed onto the rack and can rotate relative to the rack; a drive mechanism for driving the installation plates to rotate is arranged on the rack; and the installation plates can rotate relative to the rack, so that a polishing angle of the motor can be adjusted through the arrangement, and not only can plane grinding be realized but also oblique-plane grinding can be realized.

Owner:德州嘉尔雅玻璃制品有限公司

Fixing clamp used for grinding of spectacle lenses

InactiveCN108032174AAdjust the grinding angleAvoid wear and tearOptical surface grinding machinesGrinding/polishing safety devicesEyewearEngineering

The invention discloses a fixing clamp used for grinding of spectacle lenses. The fixing clamp comprises a base. Sliding grooves are formed in the two ends of the top of the base correspondingly, andfixing holes which are distributed at equal intervals are formed in the bottoms of the sliding grooves. Sliding blocks are slidably connected to the inner walls of the two sliding grooves correspondingly, and clamping blocks are welded to the top ends of the two sliding blocks correspondingly. Insertion grooves used accommodating corners of lenses are formed in the tops of the clamping blocks andare each of an arc-shaped structure. A through hole is formed in the outer wall of one side of each clamping block, a push rod is inserted into the inner wall of each through hole, and one end of eachpush rod extends into the corresponding insertion groove. By adoption of the fixing clamp, abrasion caused by traditional mechanical claws can be avoided; during grinding, the grinding angle of the lenses can be adjusted through a rotary shaft, and thus grinding is facilitated; and a fan is arranged and blows air towards the lenses through an air pipe in the grinding process so that powder generated in the grinding process can be blown away in time, the influence of the powder on ground surfaces is avoided, and the grinding effect is improved.

Owner:蚌埠中梁机械科技有限公司

Vehicle part machining equipment and machining method thereof

InactiveCN109732441AEffective clampingPrevent looseningGrinding carriagesGrinding drivesMotor vehicle partMiddle line

The invention relates to the technical field of vehicle part machining equipment, and discloses vehicle part machining equipment and a machining method thereof. The vehicle part machining equipment comprises a mounting base; a polishing table is fixedly mounted at the top of the mounting base; protective baffle plates are fixedly mounted at the top, positioned on two sides of the polishing table,of the mounting base; sleeve bases are fixedly mounted in the protective baffle plates; clamping rods are in threaded connection into the sleeve bases; one ends of the clamping rods penetrate throughand extend to the outer sides of the sleeve bases; and the ends, positioned on the outer sides of the sleeve bases, of the clamping rods are fixedly connected with rocking handles. In the vehicle partmachining equipment and the machining method thereof, clamping plates are provided and matched with the rocking handles; vehicle parts to be polished can be placed on the upper surface of the polishing table; and the rocking handles on two sides of the mounting base are respectively rotated, so that the clamping plates slide to the middle line of the polishing table to effectively clamp and fix the vehicle parts with different specifications, and the looseness of the vehicle parts during polishing is prevented to improve the stability of the polishing process.

Owner:桐乡市麦西微服饰有限公司

Casting piece grinding robot

InactiveCN109590851AGuaranteed normal rotationCases to prevent deflectionGrinding drivesGrinding machinesEngineeringGrinding wheel

The invention discloses a casting piece grinding robot comprising a working platform. The top of the working platform is provided with a grinding device, the grinding device comprises a grinding box,the grinding box (3) is internally provided with a first power chamber, a support rod is arranged inside the first power chamber, the support rod is fixedly connected to the inner wall of the first power chamber, a servo motor is arranged on the top of the support rod, a first rotating shaft is arranged on one side of the servo motor, an output shaft of the servo motor is fixedly connected to thefirst rotating shaft, a first gear is arranged on the outer side of the first rotating shaft, a tooth chain belt is arranged on the outer side of the first gear, and the first gear is engaged with thetooth chain belt. The casting piece grinding robot is provided with the grinding device, a second grinding wheel can polish materials with deep sinking parts, a grinding ball can polish objects withlarge sinking ranges, the grinding areas of the materials are better improved, meanwhile, targeted grinding on the grinding radian can be carried out, the grinding precision is improved, and the grinding quality is improved.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

Mask reparation device

ActiveCN111618710AImprove grinding effectAdjust the grinding angleGrinding drivesBelt grinding machinesEngineeringMechanical engineering

The invention provides a mask reparation device comprising a lapping mechanism. In the lapping mechanism, a first end region of a guide head is connected with a second driving assembly, a second end region abuts against a lapping belt, and the second driving assembly is used to drive the guide head to swing to adjust the lapping angle of the lapping belt. According to the device, the guide head ofthe lapping mechanism is arranged to a swinging mode, and the lapping effect of the lapping mechanism is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Mold part polishing device

PendingCN108857746AEasy to fixAdjust the grinding angleGrinding machinesGrinding work supportsEngineering

The invention discloses a mold part polishing device. The mold part polishing device comprises a worktable, wherein a door-shaped bracket is arranged on the upper surface of the worktable; a No. 1 sliding rail is arranged on the upper surface in the door-shaped bracket; the No. 1 sliding rail is in sliding connection with a No. 1 electric sliding block; a No. 1 rotary motor with a downward rotaryend is arranged on the lower surface of the No. 1 electric sliding block; a controller is arranged on the upper surface of the worktable and is located on the surface of the right side of the door-shaped bracket; an electric connector is arranged at the right end of the lower surface of the worktable; the electric connector is electrically connected with the controller through a lead wire; the controller is electrically connected with a No. 1 electric sliding block, a No. 1 hydraulic retractable rod, a No. 2 electric sliding block, a No. 1 rotary motor, each No. 2 rotary motor, a No. 2 hydraulic retractable rod, a No. 3 rotary motor and a pair of electric push rods through lead wires. The mold part polishing device disclosed by the invention has the beneficial effects that regular parts can be conveniently fixed and polished and cylindrical parts can be fixed and polished; a polishing angle can be adjusted.

Owner:天津冰一科技有限公司

Mask Restoration Equipment

ActiveCN111618710BImprove grinding effectAdjust the grinding angleGrinding drivesBelt grinding machinesMechanical engineeringPhysics

The present application provides a reticle repairing device. The reticle repairing device includes a grinding mechanism. In the grinding mechanism, the first end of the guide head is connected to the second driving assembly, the second end abuts against the grinding belt, and the second The drive assembly is used to drive the guide head to swing to adjust the grinding angle of the grinding belt. In the present application, the grinding effect of the grinding mechanism is improved by setting the guide head of the grinding mechanism in a swingable manner.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Trimming device for broom bristle production

PendingCN114631684AAdjust the grinding angleMeet the functional requirements of different shapesDispersed particle filtrationBrushesBroomStructural engineering

Owner:芜湖立新清洁用品有限公司

Multi-directional edge grinding equipment for mailbox production process

PendingCN113386003AEasy to grindImprove efficiencyEdge grinding machinesGrinding drivesGear wheelIndustrial engineering

The invention discloses multi-directional edge grinding equipment for a mailbox production process, and relates to the technical field of mailbox production and processing. The multi-directional edge grinding equipment aims to solve the problems that for existing plate processing equipment, cleaning needs to be carried out by manually holding grinding equipment by a worker, and consequently the efficiency is low, the labor cost is increased, and meanwhile, the grinding consistency is inconvenient to maintain. According to the technical scheme, the multi-directional edge grinding equipment comprises two mounting plates, a steering adjusting mechanism is arranged between the two mounting plates, a fixing shaft is connected to the bottom of the steering adjusting mechanism in a rotating mode, a hanging plate is fixedly connected to the bottom end of the fixing shaft, a sleeve is connected into the hanging plate in a rotating mode, the exterior of the sleeve is fixedly sleeved with a second gear, and the two sides of the sleeve movably sleeve grinding mechanisms. The multi-directional edge grinding equipment has the advantages that the two sides of a plate can be conveniently and simultaneously ground, the grinding efficiency is improved, the labor cost is saved, in addition, the grinding consistency is guaranteed, meanwhile, the grinding angle can be adjusted, the applicability of the equipment is improved, and the equipment is suitable for market popularization.

Owner:淮北鑫亨文金属制品有限公司

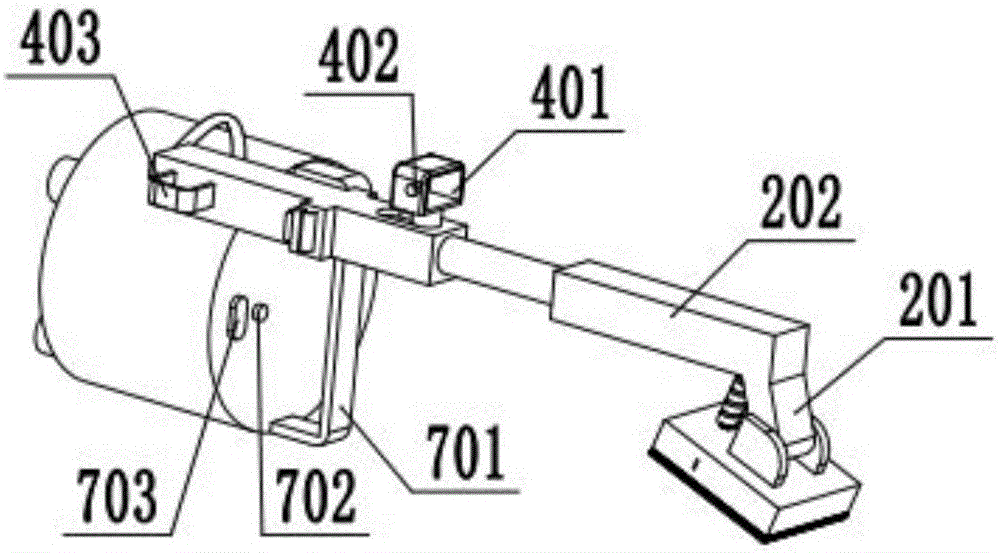

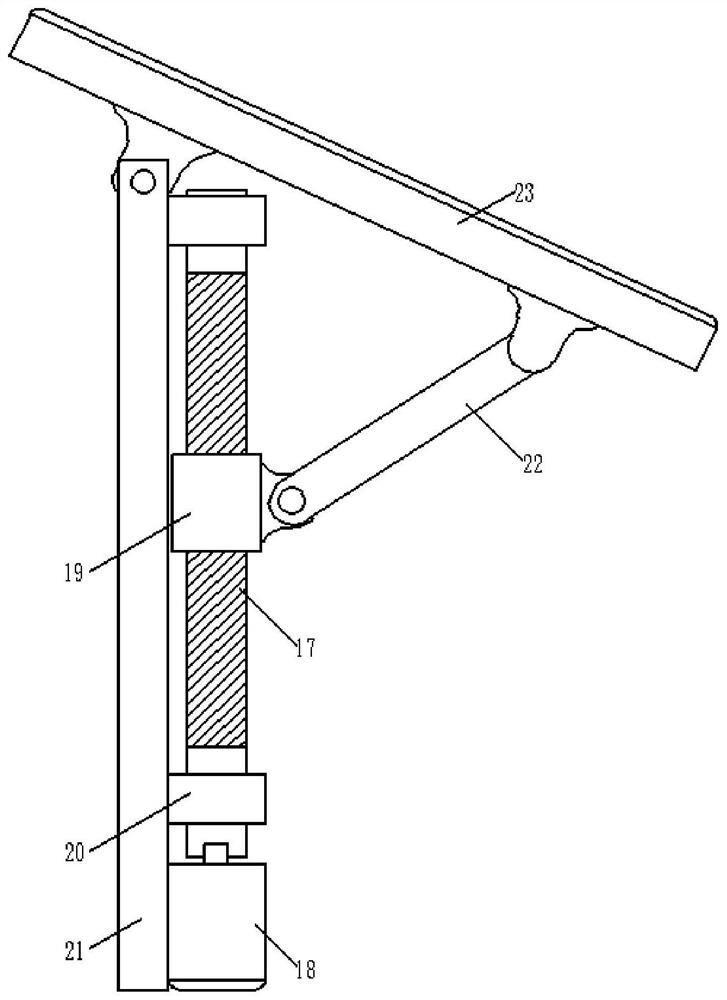

A car roof groove grinding processing production equipment with multi-angle movement

ActiveCN112139917BAdjust the grinding angleImprove grinding efficiencyGrinding drivesGrinding machinesSanderGear wheel

The invention discloses an automobile roof groove grinding and processing production equipment with multi-angle movement. A chute, a rotor is arranged inside the grinder, and a second synchronizing gear is installed on the output end of the rotor, a workbench is installed in the middle of the frame, and a limit block is set above one side of the workbench, the said An adsorption mechanism is arranged under the inner working table of the frame. In the present invention, by arranging the first small shaft and the telescopic rod inside the sander and the bottom of the connecting seat, the setting of the first small shaft is convenient for the sander to perform left and right operations. Angle adjustment, and through the setting of the telescopic rod, it is easy to adjust the grinding angle of the grinding disc, so as to fit the surface of the roof cover, avoid the operator's fatigue caused by manual operation of the sander for a long time, and is conducive to the grinding efficiency of the roof cover and sanding effect.

Owner:CHONGQING TECH & BUSINESS UNIV

Automatic burr removing and polishing equipment

PendingCN113752114AAdjust the grinding angleSimple structureEdge grinding machinesGrinding carriagesElectric machineDrive shaft

The invention discloses automatic burr removing and polishing equipment which comprises a workbench, wherein a first electric cylinder is fixedly arranged at the end, close to the left side end face, of the workbench; a screw rod is vertically arranged in an adjusting groove; a driven gear is fixedly arranged at the top end of the screw rod; a sliding block is in external threaded connection with the screw rod; a connecting rod is fixedly arranged on the sliding block; an adjusting motor is fixedly arranged at the upper end of a fixing block on the supporting rod; a driving gear is fixedly connected to the top end of a driving shaft; a mounting base is hinged to the bottom of the supporting rod; a polishing motor is fixedly arranged on the mounting base; a sliding groove is transversely formed in the right side of a rectangular through groove in the workbench; a plurality of second electric cylinders are fixedly arranged on the sliding groove; a feeding plate is fixedly arranged at the top ends of piston rods of the second electric cylinders; and a third electric cylinder is fixedly arranged at the end of the right side of the workbench. Adjustment of the grinding angle can be achieved through the adjusting motor.

Owner:苏州聚汇元精密科技有限公司

A polishing device for new energy vehicle wheel hub processing

ActiveCN111230710BRealize polishing workRealize polishing and chamfering operationsEdge grinding machinesGrinding carriagesDrive wheelNew energy

The invention discloses a polishing device for new energy automobile wheel hub processing, which relates to the technical field of auto parts processing and includes a workbench, a wheel hub top surface polishing mechanism, a wheel hub side polishing mechanism, and a wheel hub limit rotation mechanism. The wheel hub top surface polishing mechanism is arranged on Above the workbench, the hub side polishing mechanism is set on the top of the workbench, and the hub limit rotation mechanism is set under the workbench; the hub limit rotation mechanism includes a height adjustment component, which is used to clamp the inner circle of the hub. The fixed assembly and the rotating assembly used to drive the rotation of the hub, and a through hole is provided on the top of the workbench for the inner circle fixed assembly of the hub to pass through. The invention clamps the inner circle of the hub and drives the hub to rotate under the action of the hub limit rotation mechanism, and can realize the angle adjustment of the grinding wheel through the hub side polishing mechanism, and then realizes the polishing and chamfering operation on the top surface of the hub.

Owner:山东荣升重型机械股份有限公司

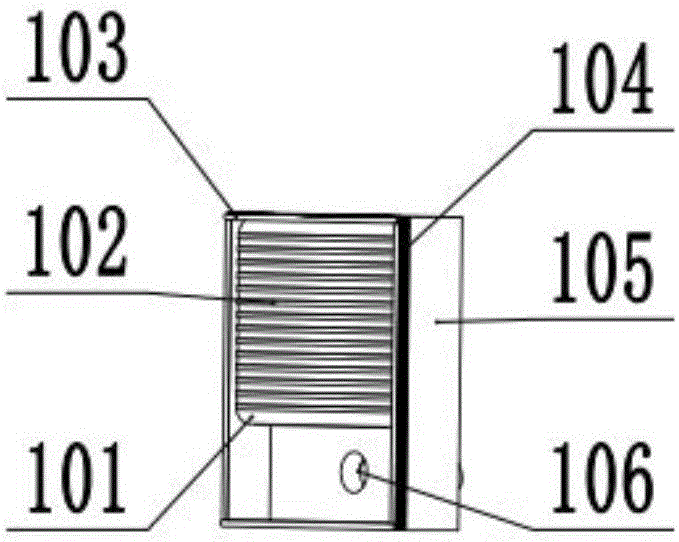

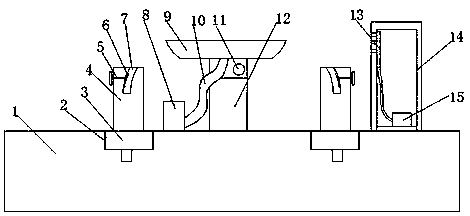

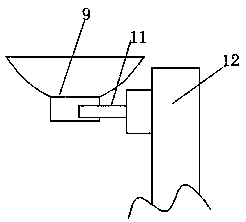

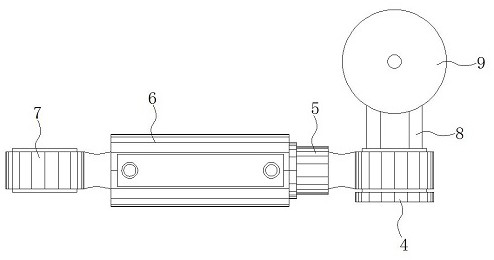

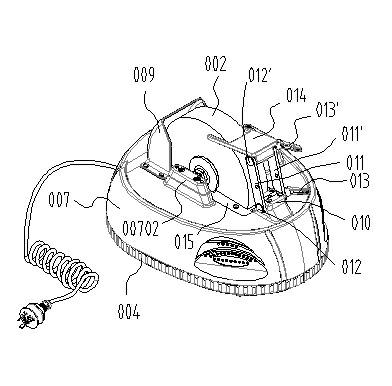

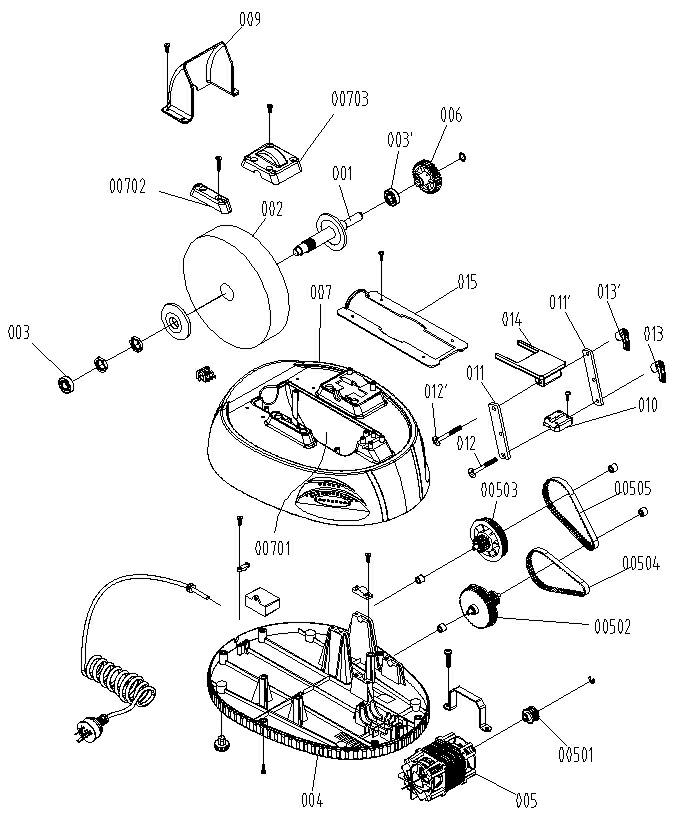

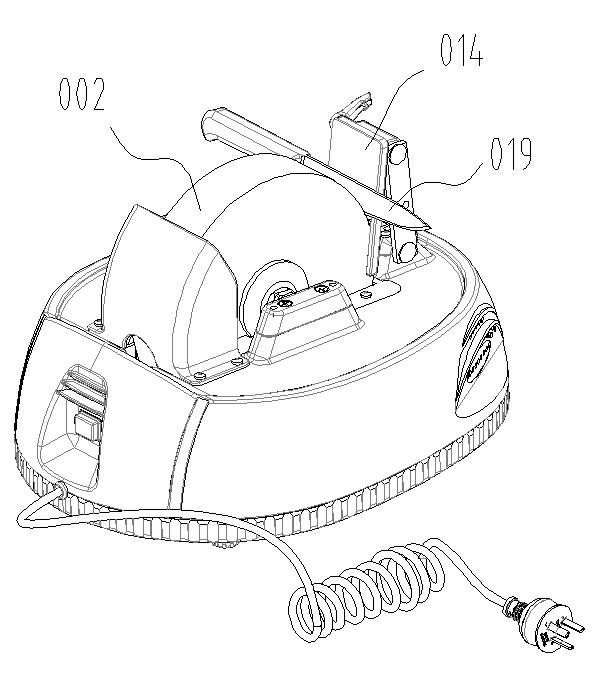

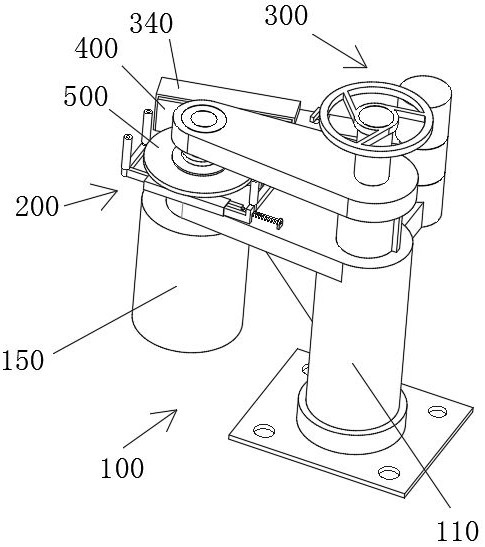

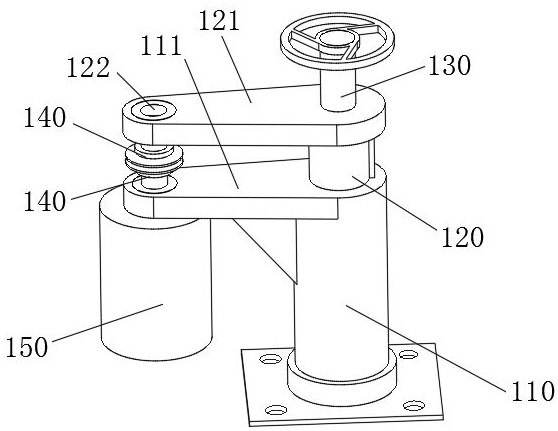

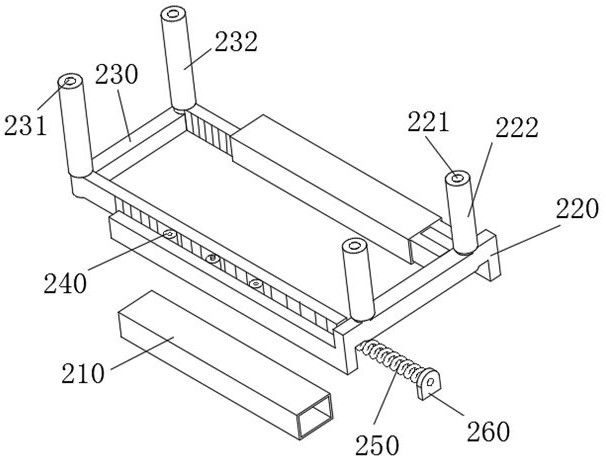

Multipurpose sharpening machine

ActiveCN102672559AEasy to operateReduce operating intensityGrinding drivesOther manufacturing equipments/toolsAgricultural engineeringEngineering

The invention discloses a multipurpose sharpening machine which comprises a base, a motor, a grinding wheel, a tool support and a machine casing. A grinding wheel shaft is respectively installed on a left bearing support seat and a right bearing support seat which are arranged on a casing of the machine casing through a left bearing and a right bearing, the casing of the machine casing between the left bearing support seat and the right bearing support seat is sunk downwards to form a groove for containing the lower portion of the grinding wheel and containing water or grinding fluid, a gap is arranged between the groove and the lower portion of the grinding wheel, the motor is in transmission connection with a big gear arranged at the right end of the grinding wheel shaft through a transmission mechanism, a left bearing cap is arranged on the left bearing, and a right bearing cap is arranged on the right bearing and the casing of the machine casing. A grinding wheel protective cover is arranged on the casing of the machine casing at the back end of the groove, a clamping plate support block is arranged on the casing of the machine casing at the front end of the groove, the left ends of a left clamping plate and a right clamping plate are respectively hinged with the left side and the right side of the clamping plate support block through a bolt A and a regulating nut B, and the upper ends of the left clamping plate and the right clamping plate are respectively hinged with the left side and the right side of the front end portion of the tool support through a bolt C and a regulating nut D.

Owner:ZHEJIANG JIAHONG TOOL MFG CO LTD

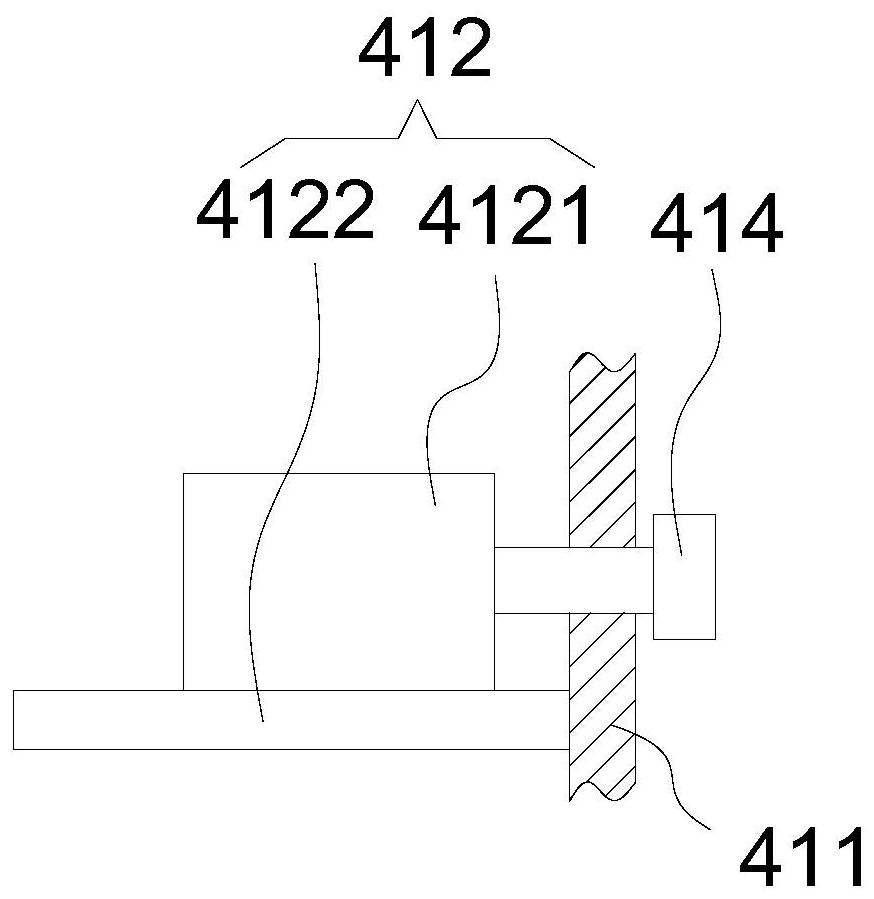

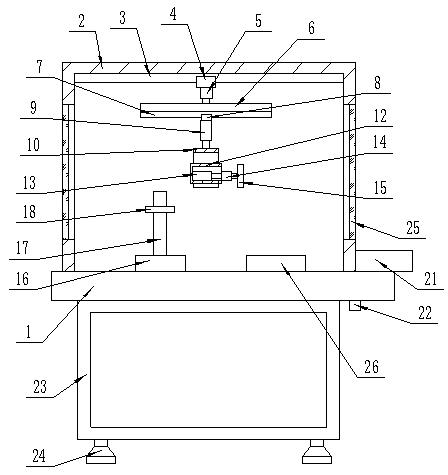

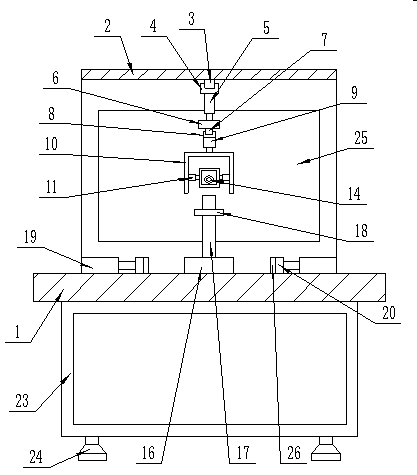

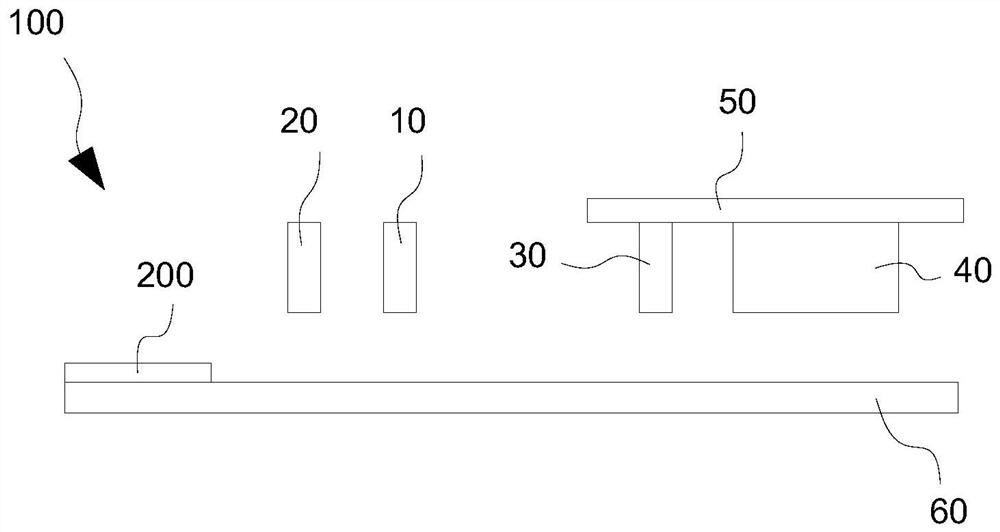

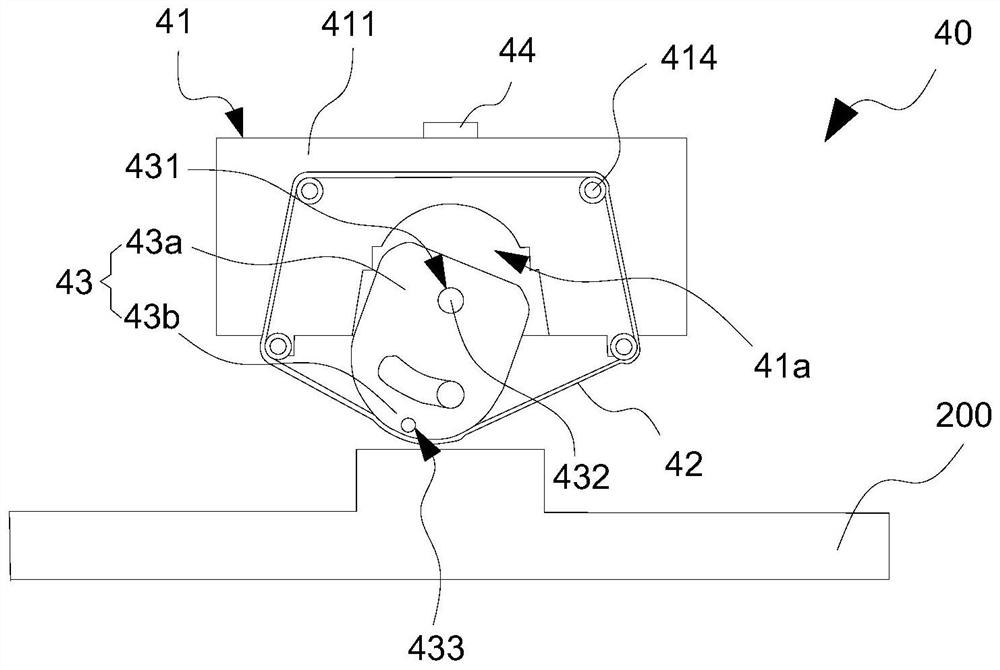

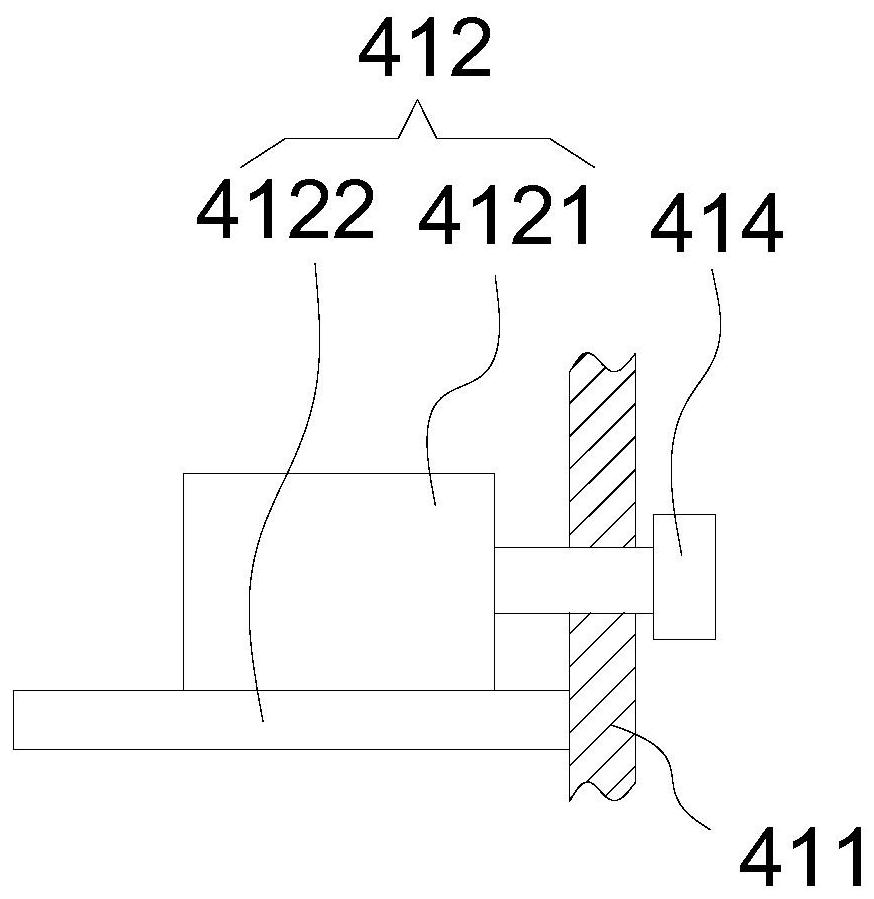

Four-station water drill inclined plane milling and casting machine

InactiveCN100546768CAdjust the grinding angleGrinding and polishing evenlyEdge grinding machinesEngineeringSurface grinding

The invention relates to a quadruple work place water drill angular surface grinding machine, which comprises a framework, wherein, a rotation rack is arranged on the framework; four sides of the rotation rack are respectively provided with a ram head for fixing a cramping apparatus; a grinding work place, a rough polishing work place, a fine polishing work place and an up-down blanking vacancy are arranged on the framework and are respectively corresponding to the four ram heads; a grinding roller milling apparatus is arranged on the grinding work place; the rotation axis of the grinding roller is connected with a translational apparatus used for driving the grinding roller to do axial reciprocating translational motion; a group of burnishing roller polishing apparatuses is respectively arranged on the rough polishing work place and the fine polishing work place; the rotation axis of the burnishing roller is connected with the translational apparatus used for driving the burnishing roller to do axial reciprocating translational motion. The technical proposal adopts the grinding roller to grind and process water drill blank, so as to increase the single-unit processing amount of the water drill blank, and adopts the translational apparatus for driving the grinding roller to do axial reciprocating translational motion, so as to ensure even grinding of the water drill blank. Compared with the homogeneous equipment, the quadruple work place water drill angular surface grinding machine has the advantages of low cost, high production volume, good reliability, high processing efficiency, stable operation, convenient adjustment, etc.

Owner:虞雅仙

A device for grinding uniform edges and corners of mosaic tiles

InactiveCN106271953BThe corners are evenly groundPolished evenlyEdge grinding machinesGrinding carriagesLinear actuatorIdler-wheel

The invention relates to a polishing device, in particular to a uniform side and corner polishing device for mosaic tiles. The technical aim of the uniform side and corner polishing device for the mosaic tiles is to enable side and corner polishing to be uniform. In order to achieve the above technical aim, the uniform side and corner polishing device for the mosaic tiles is provided and comprises a base plate, a right support, an electric wheel, a fixing plate, a first pull wire, a first fixed pulley, a second fixed pulley, a first swing base, a left support, a wedge block, a contact idler wheel, a lifting rod, a second swing base, a second pull wire, a fixing block, a third spring, a first spring, a second linear actuator, a rotation motor, a pressing plate, a containing plate and the like. The left end and the right end of the top of the base plate are provided with the left support and the right support correspondingly. By means of the uniform side and corner polishing device, the effect of being uniform in side and corner polishing is achieved; when the uniform side and corner polishing device is used for side and corner polishing of the mosaic tiles, the polishing angle can be adjusted, and polishing can be more comprehensive; and meanwhile, the manpower for polishing is saved.

Owner:CHONGQING RYAN PAINT CO LTD

Polishing device with multi-angle driving structure

PendingCN114147579ASave sanding timeImprove flatnessGrinding drivesGrinding machinesReciprocating motionEngineering

The invention discloses a multi-angle driving structure grinding device, and belongs to the field of grinding devices. The device comprises a grinding head, an EAP driver, a fixed shell, a transmission rod, a connector and a voltage controller. The EAP driver is fixedly connected with the fixed shell, and the EAP driver is connected with the voltage controller and the power source through wires. The EAP driver generates axial deformation and axial driving force when powered on, the output axial deformation and axial driving force of the EAP driver are controlled by controlling the frequency and magnitude of voltage output by the voltage controller, the EAP driver and the transmission rod are connected through the fixing shell, and the driving force is transmitted out. Different types of grinding heads are selected according to the grinding environment, the transmission rod and the grinding heads are connected through the connector, and then the grinding angles of the grinding heads are adjusted. And the polishing head is driven to do reciprocating motion through the driving effect of the EAP driver, so that translational polishing of the structure test area is realized.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Wall surface smoothing device for building construction

InactiveCN114378663AEasy to replaceMaintain smooth efficiencyGrinding drivesGrinding feed controlPolishingAir pump

The building construction wall surface grinding device comprises a control block, a shell is fixedly arranged on the left end face of the control block, a grinding cavity with a leftward opening is formed in the left end face of the shell, and a grinding motor is fixedly arranged in the control block; the grinding force of the grinding wheel on the wall surface is determined through the torsional force borne by the torsion shaft, then the abrasion condition of the grinding wheel is judged, the grinding wheel can be conveniently replaced in the first time, the grinding efficiency is kept, the placement angle of the grinding wheel is detected through the height difference between the two floating blocks, and the grinding efficiency is improved. The polishing angle of the polishing wheel can be conveniently and visually adjusted according to the perpendicularity of the wall face so as to improve the polishing quality, dust generated in the polishing process can be recycled through the air pump, it is prevented that dust flies to affect the health of a user, and the safety in the using process is improved.

Owner:邰雨

Saw blade grinding equipment

InactiveCN109986134AEffective sandingReasonable designSawing tools dressing arrangementsTool bitEngineering

The invention relates to saw blade grinding equipment which comprises an operation table, a grinding platform rotatably installed at the upper end of the operation table, a supporting frame and a grinding wheel grinding mechanism; one end of the supporting frame is hinged to the upper end of the grinding platform; a cylindrical seat body is vertically and rotatably arranged on any side of the other end of the supporting frame; the supporting frame can be overturned until being horizontally folded at the upper end of the grinding platform or be overturned until being vertically abutted againstthe upper end of the grinding platform; the grinding wheel grinding mechanism is movably installed at the upper end of the operation table through a displacement moving mechanism with a grinding wheelbeing vertically arranged; and the displacement moving mechanism can drive the grinding wheel grinding mechanism to move in a horizontal plane, can drive the grinding wheel grinding mechanism to moveuntil the grinding wheel is attached to any side of the outer edge of a saw blade when the saw blade is in a horizontal state and can drive the grinding wheel grinding mechanism to move until the outer edge of the grinding wheel is in contact with the outer edge of the saw blade when the saw blade is in a vertical state. The saw blade grinding equipment has the advantages that operation is simpleand convenient, and a tool bit and the two sides of the saw blade can be effectively ground.

Owner:湖北鄂嘉科技有限公司

Glass round piece polishing device

InactiveCN112192364AAchieve positioningPrecise positioningEdge grinding machinesGrinding drivesGear drivePolishing

The invention relates to the technical field of glass polishing, in particular to a glass round piece polishing device. The glass round piece polishing device comprises a rotating module, the rotatingmodule comprises a supporting cylinder, the inner wall of the supporting cylinder is slidably sleeved with a sliding sleeve, a threaded groove is formed in the inner wall of the sliding sleeve, a threaded rod is connected with the inner wall of the sliding sleeve in a screwed mode, and the bottom end of the threaded rod is rotationally connected with the inner bottom surface of the supporting cylinder. According to the glass round piece polishing device, through the arrangement of a positioning module, a U-shaped rod II moves, a gear drives a U-shaped rod I to move reversely for the same distance, so that two rotating sleeves I and two rotating sleeves II move close to each other to clamp and limit a glass round piece, the circle center position of the glass round piece coincides with theaxis of the output end of a motor, accurate positioning of the circle center of the glass round piece is achieved, operation is easy, two rubber suction cups clamp and fix the glass round piece through the arrangement of the rubber suction cups and the sliding sleeve, the motor can conveniently drive the glass round piece to rotate, and therefore grinding is conducted.

Owner:梁云招

Multipurpose sharpening machine and tool setting plate for sharpening machine

ActiveCN102672559BEasy to GrindEasy to operateGrinding drivesOther manufacturing equipments/toolsBlade plateGear wheel

The invention discloses a multipurpose sharpening machine which comprises a base, a motor, a grinding wheel, a tool support and a machine casing. A grinding wheel shaft is respectively installed on a left bearing support seat and a right bearing support seat which are arranged on a casing of the machine casing through a left bearing and a right bearing, the casing of the machine casing between the left bearing support seat and the right bearing support seat is sunk downwards to form a groove for containing the lower portion of the grinding wheel and containing water or grinding fluid, a gap is arranged between the groove and the lower portion of the grinding wheel, the motor is in transmission connection with a big gear arranged at the right end of the grinding wheel shaft through a transmission mechanism, a left bearing cap is arranged on the left bearing, and a right bearing cap is arranged on the right bearing and the casing of the machine casing. A grinding wheel protective cover is arranged on the casing of the machine casing at the back end of the groove, a clamping plate support block is arranged on the casing of the machine casing at the front end of the groove, the left ends of a left clamping plate and a right clamping plate are respectively hinged with the left side and the right side of the clamping plate support block through a bolt A and a regulating nut B, and the upper ends of the left clamping plate and the right clamping plate are respectively hinged with the left side and the right side of the front end portion of the tool support through a bolt C and a regulating nut D.

Owner:ZHEJIANG JIAHONG TOOL MFG CO LTD

Grinding device for mechanical manufacturing

InactiveCN111496628BApplicable useImprove grinding efficiencyGrinding carriagesRevolution surface grinding machinesRatchetCircular disc

The invention provides a grinding device for mechanical manufacturing, including a grinding device, an angle adjustment mechanism and an intermittent movement mechanism; the grinding device includes a grinding head for grinding parts, the grinding head is fixedly connected to one end of a connecting rod, and the other end of the connecting rod Connected with the output shaft of the first motor, the first motor is fixed on the support frame, the support frame is slidably connected with the support seat through the sliding assembly, and the bottom of the support seat is provided with an intermittent motion mechanism for driving its rotation; the intermittent motion mechanism includes a ratchet , the center of the ratchet is provided with a rotating shaft connected with it through a key, the upper end of the rotating shaft is fixed to the support seat, the ratchet is engaged with the driving pawl, and the driving pawl is connected with the reciprocating swing mechanism that drives it to swing; Grinding device for mechanical manufacturing of notch and through hole grinding of similar parts.

Owner:HENAN IND & TRADE VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com