Four-station water drill inclined plane milling and casting machine

A four-station, grinding and polishing machine technology, applied to grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problem of increasing the volume of the machine, increasing the cost of machine materials and use costs, and not suitable for And other problems, to achieve the effect of good reliability, increase the number of single-group processing, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

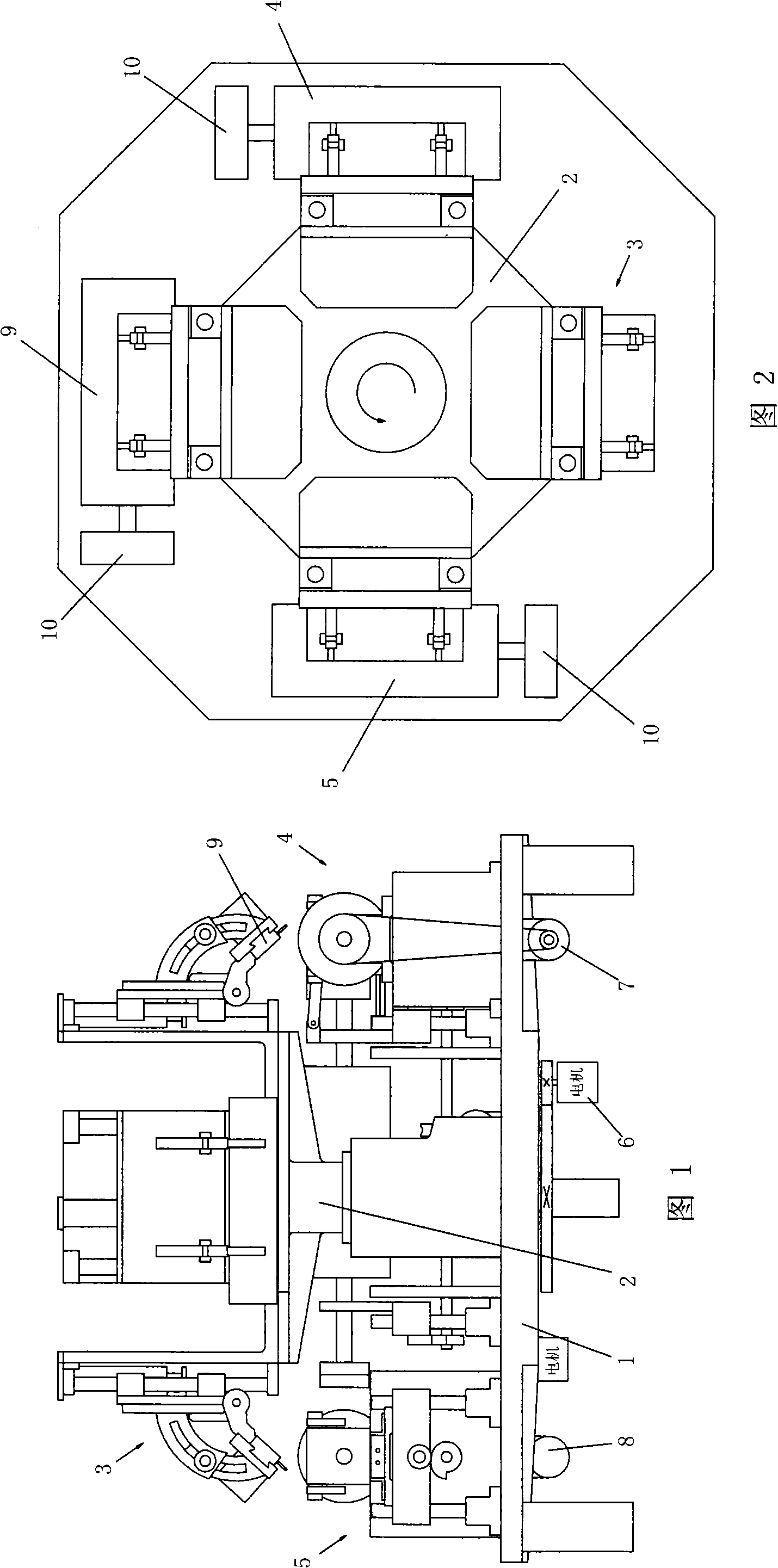

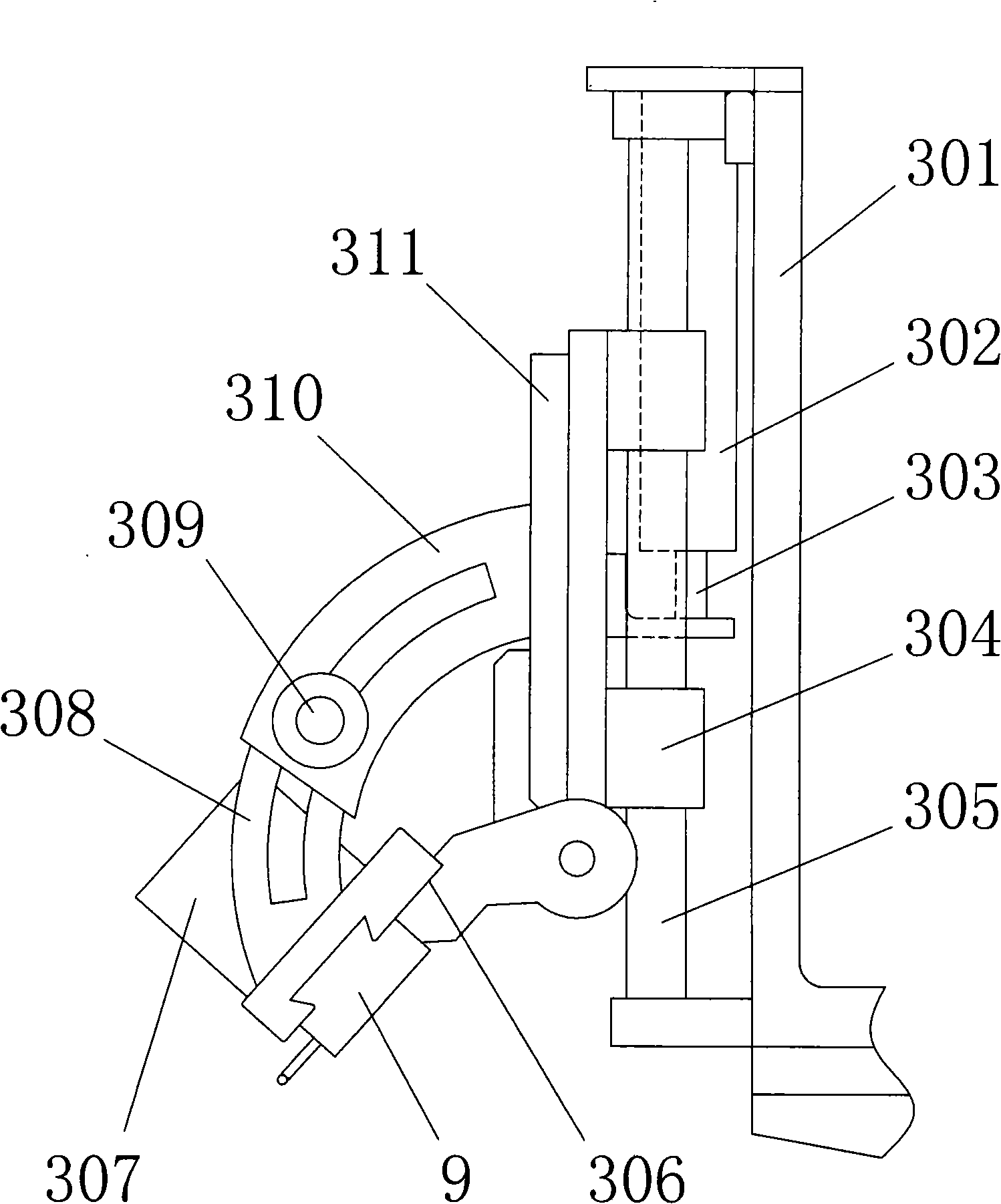

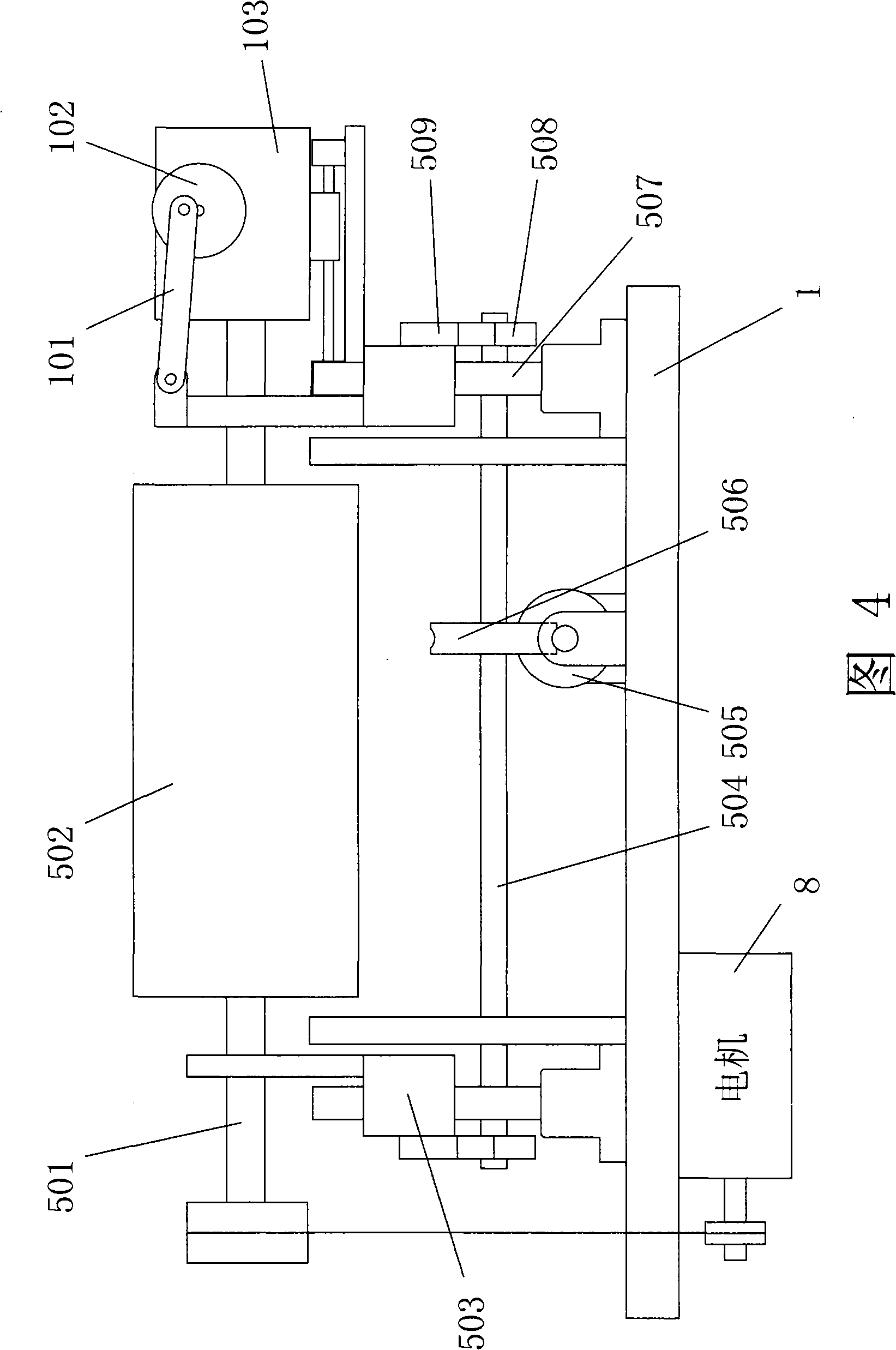

[0029] A four-station rhinestone bevel grinding and polishing machine as shown in Fig. 1 and Fig. 2 includes a frame 1 on which a rotating frame 2 is arranged. A machine head 3 with a fixed fixture is provided, and the frame 1 is provided with a grinding station, a rough polishing station, a fine polishing station and a loading and unloading space, corresponding to the four machine heads 3 respectively. The cutting station is provided with a grinding mechanism 4, as shown in Figure 6, the grinding mechanism 4 includes a bracket 403 and a grinding roller 402 mounted on the bracket 403, the rotating shaft 401 of the grinding roller 402 and the bracket 403 can be Rotation and axial sliding connection, one end of the rotating shaft 401 is in transmission connection with the grinding motor 7 arranged on the frame 1, and the other end of the rotating shaft 401 is connected with a translation mechanism 10 that drives it to perform axial reciprocating translation, wherein the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com