Optical lens automatic milling and grinding machine and automatic milling and grinding method thereof

A technology for optical lenses and milling machines, which is applied to optical surface grinders, grinding machine parts, grinding machines, etc., can solve the problems of low equipment efficiency and high labor costs, reduce labor costs, improve utilization, and overcome high manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

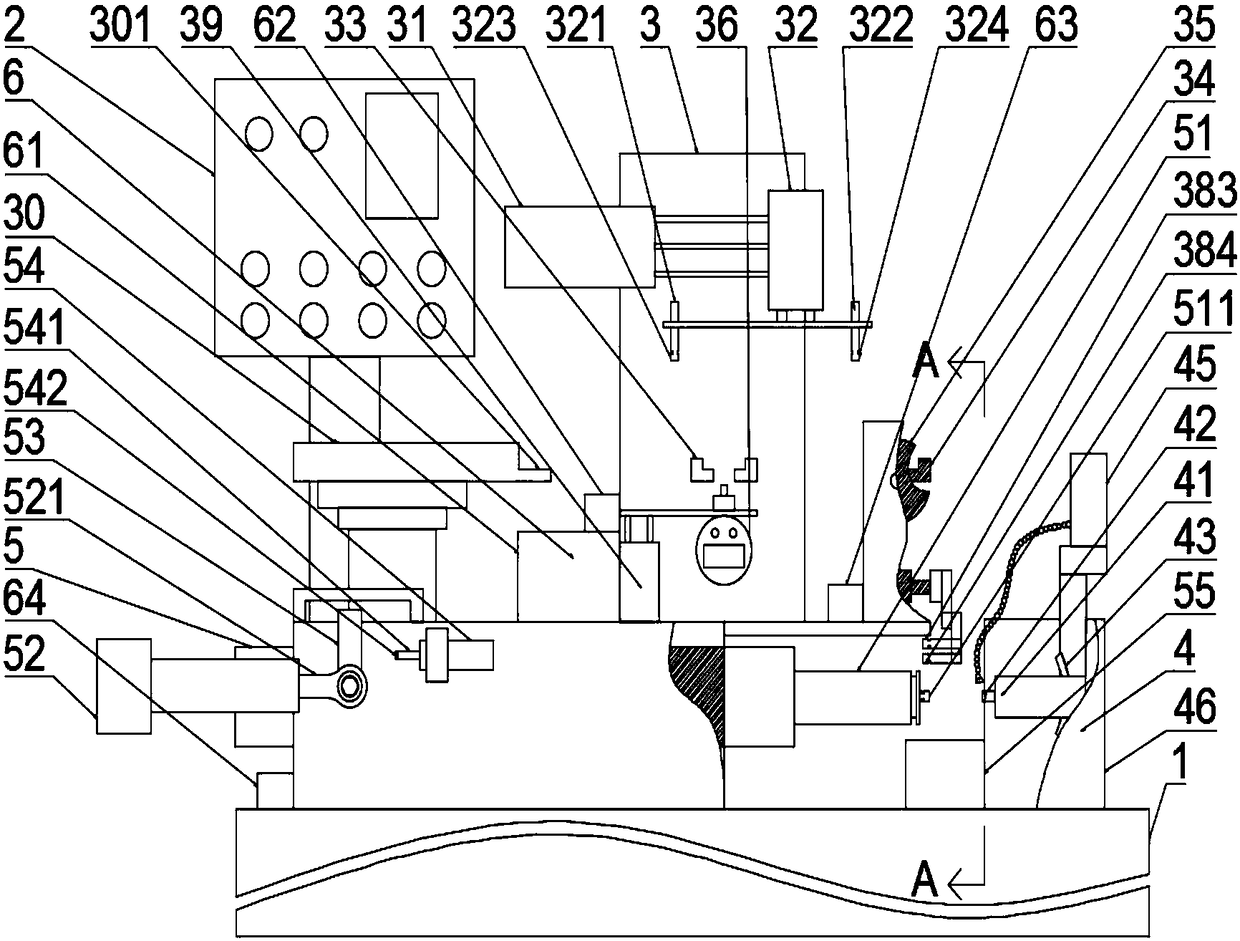

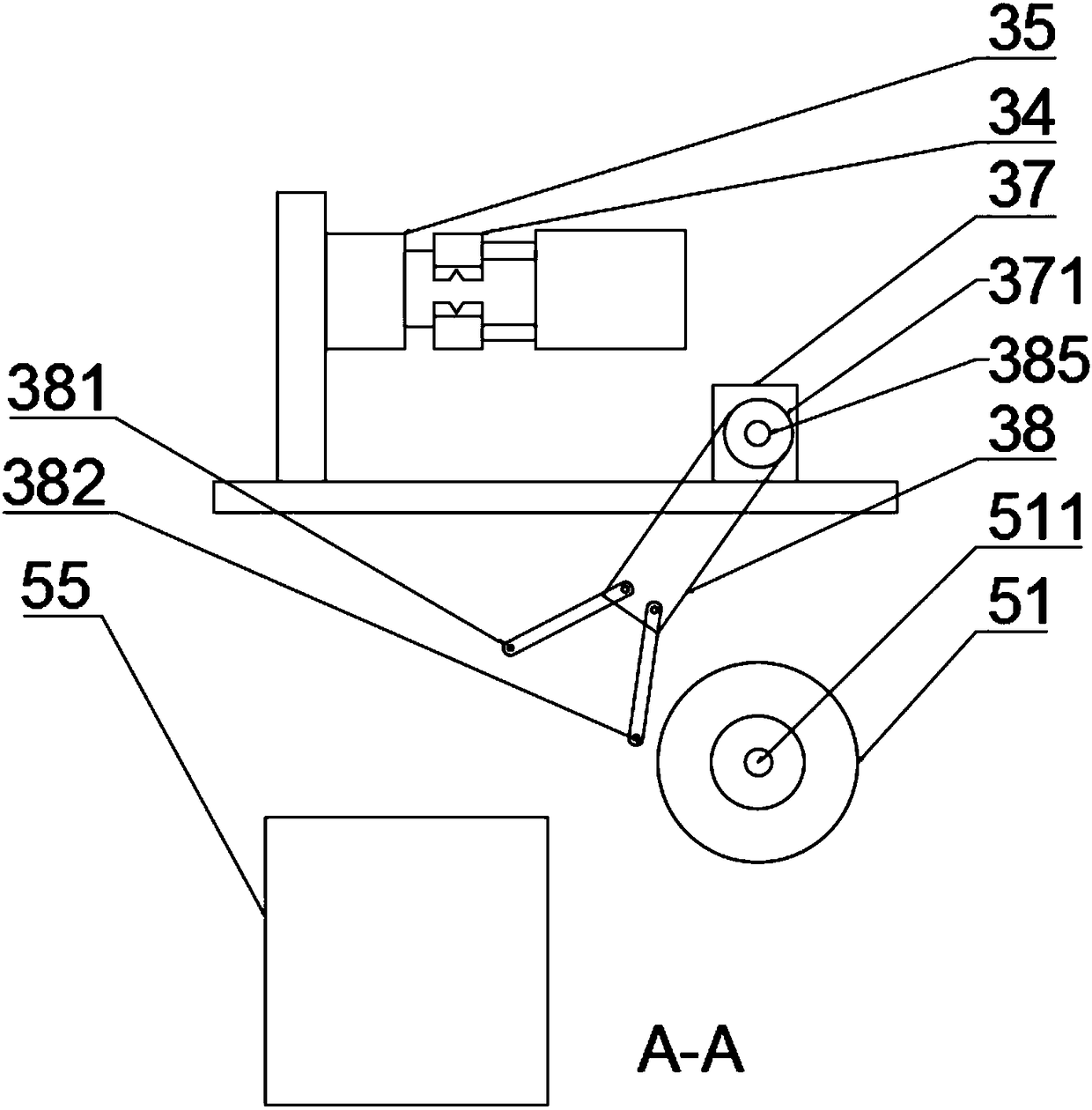

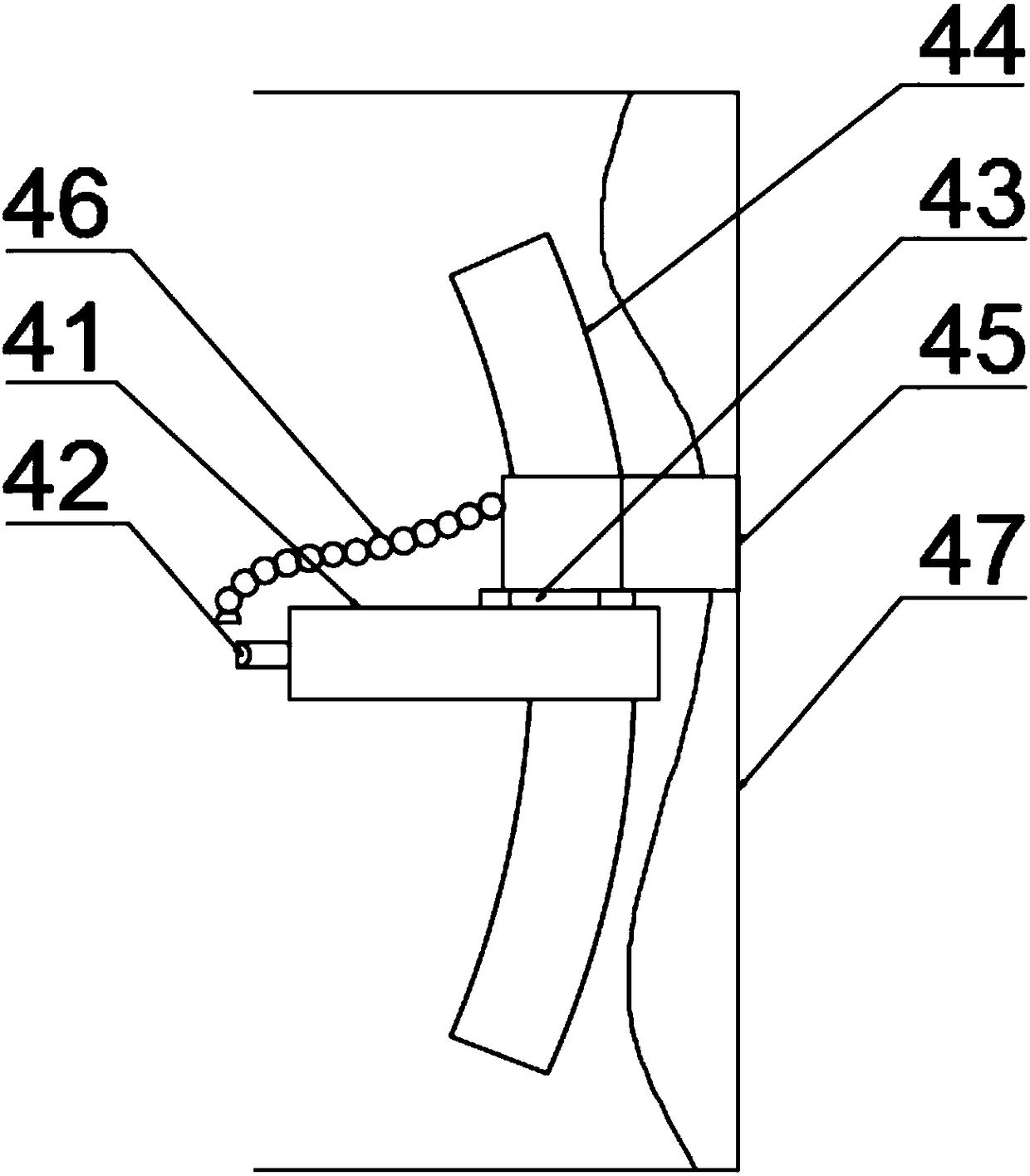

[0026] see Figure 1~3, an optical lens automatic milling machine and an automatic milling method thereof according to the present invention, comprising a milling chassis 1, a controller 2 arranged on the milling chassis 1, an automatic feeding mechanism 3, a processing mechanism 4, Feeding mechanism 5, vacuum control system 6, described automatic feeding mechanism 3 comprises automatic feeding device 30, the discharge port 301 that is arranged on described automatic feeding device 30, the first air cylinder 31, and described first air cylinder The second cylinder 32 connected to the piston rod of 31, the first fetching arm 321 and the second fetching arm 322 connected to the second cylinder 32, the first positioning device arranged under the second cylinder 32 33. The second positioning device 34 arranged under the second cylinder 32, the first rotating device 35 connected to the second positioning device 34, the second rotating device 37, and the second rotating device 37 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com