Lipstick forming and tube entering integrated machining die

A mold-processing, one-piece technology, applied to household appliances, types of packaging items, applications, etc., can solve problems such as shedding damage, mold release and insertion, tube extraction cannot be performed at the same time, and lipstick remains on the bottom mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

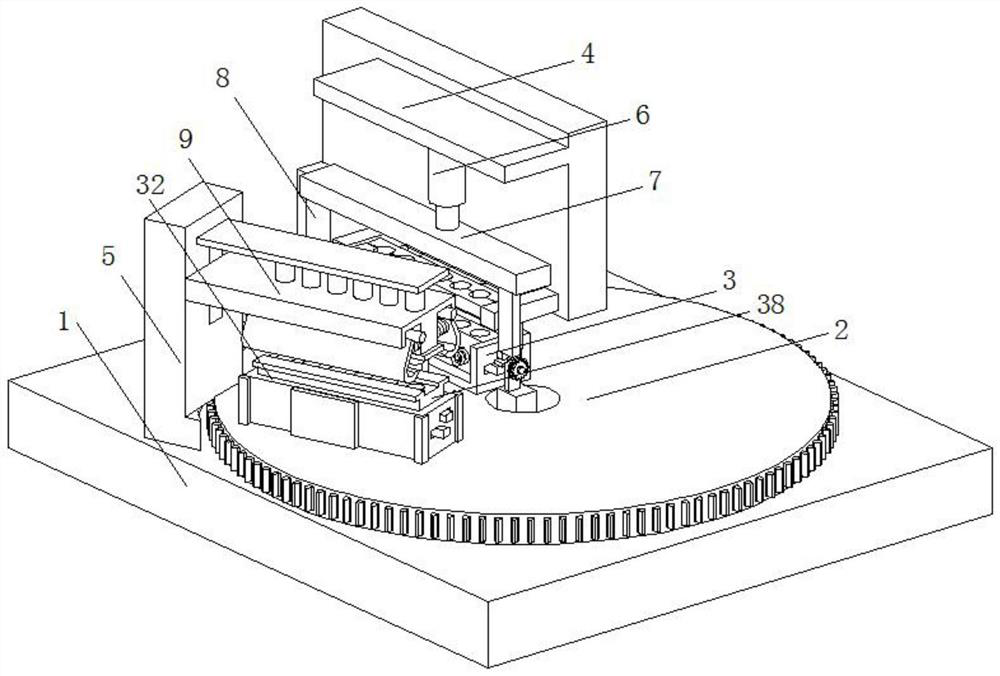

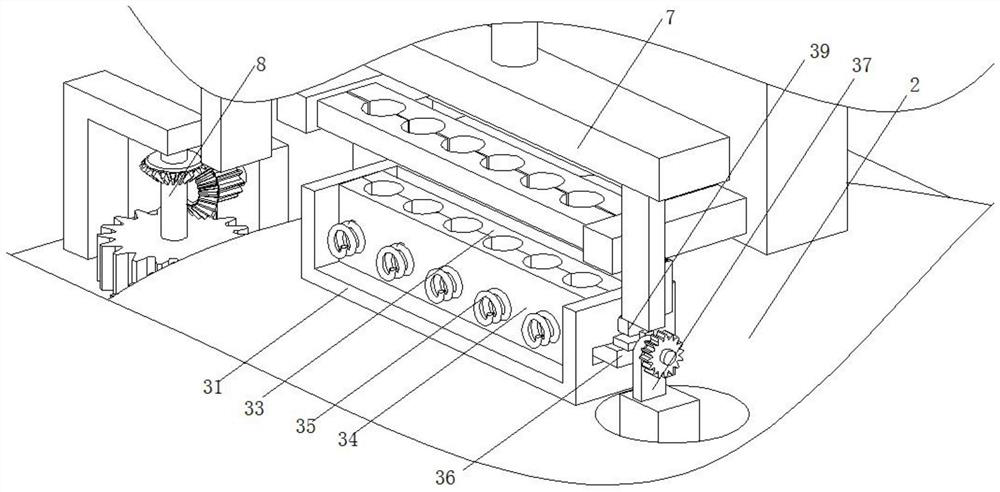

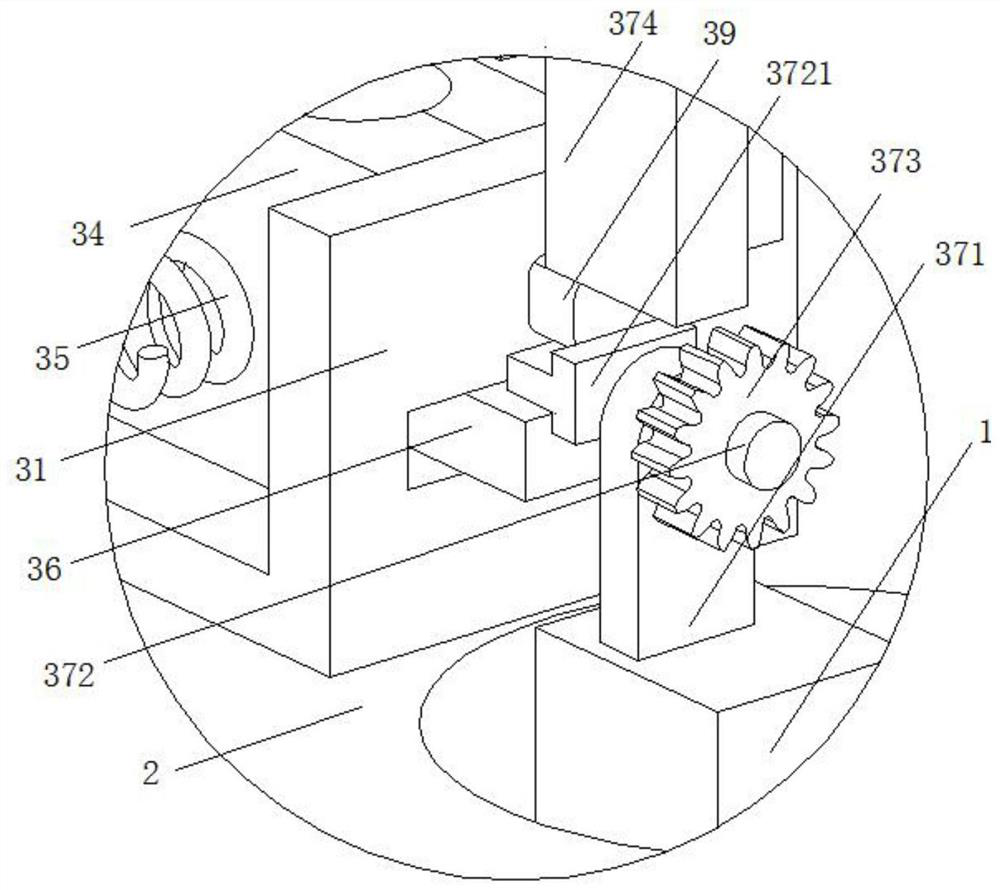

[0031] A lipstick forming tube integrated processing mold, such as Figure 1-Figure 4 As shown, it includes a workbench 1, the top of the workbench 1 is rotatably connected with a transport chassis 2, the top of the transport chassis 2 is provided with an auxiliary extubation mechanism 3 with the function of opening the bottom mold, and the surface of the workbench 1 is fixedly connected with a Mounting seat 1 4 and mounting seat 2 5, the surface of mounting seat 1 4 is fixedly connected with electric push rod 6 through bolts, the output shaft of electric push rod 6 is clamped with pressure seat 7, and pressure seat 7 is far away from the 2 axis points of the transport chassis One side is provided with an interlocking device 8, the surface of the mounting base 25 is provided with a synchronous mechanism 9 with an automatic demoulding function, a hole is opened at the axis point of the transport chassis 2, and a piece protrudes from the hole where the workbench 1 is located to f...

Embodiment 2

[0038] Such as Figure 5-7 As shown, the synchronous mechanism 9 includes a stripping seat 91, the surface of the stripping seat 91 is slidingly connected with the surface of the mounting seat 25, and the inner rotation of the stripping seat 91 is connected with a connecting rod 92, and the surface of the connecting rod 92 is welded with an arc Shape hook plate 93, back-moving spring 94 is welded between arc-shaped hook plate 93 and demoulding seat 91, and the inside of demoulding seat 91 is provided with auxiliary component 95, and the surface of demoulding seat 91 is welded and fixed with the surface of pressure seat 7, By setting the synchronous mechanism 9 and utilizing the mutual operation between the various internal structures, the pressure seat 7 can drive the second mold 32 to automatically take off the film during the tube pressing and tube pulling, and further improve the overall efficiency of lipstick tube insertion The purpose is to achieve the effect that the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com