Sports equipment casting machining device

A technology for processing devices and sports equipment, applied in grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc. The effect of saving manpower, novel structure and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

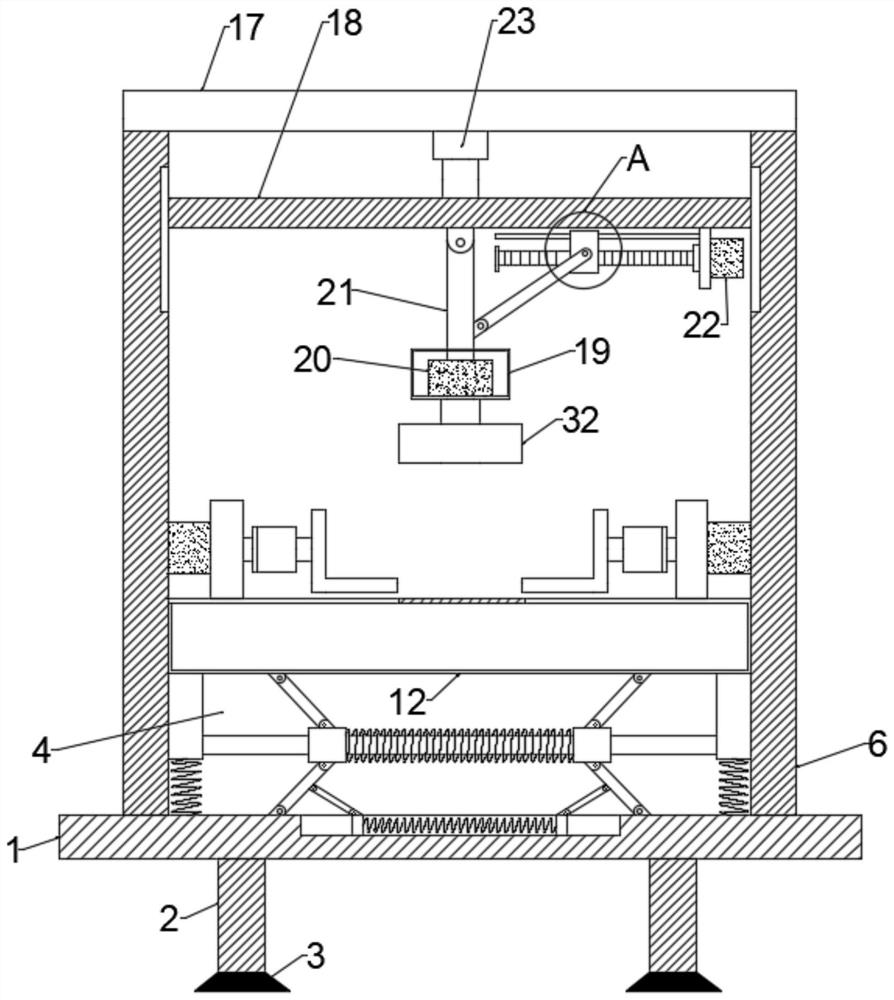

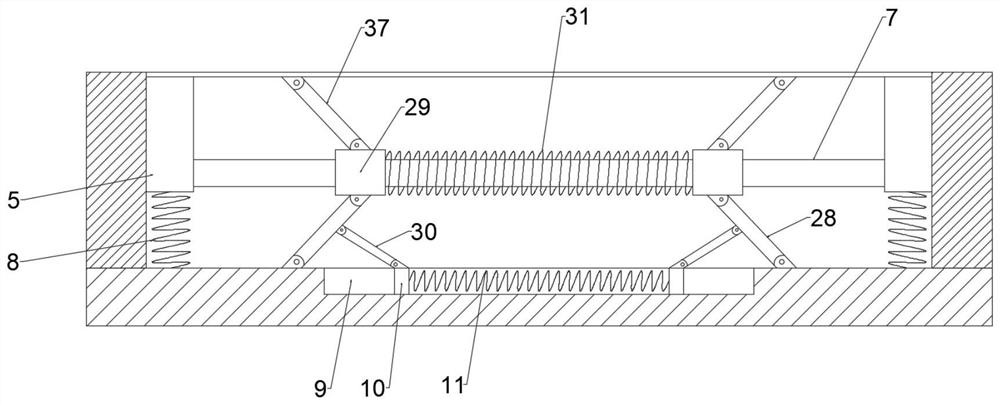

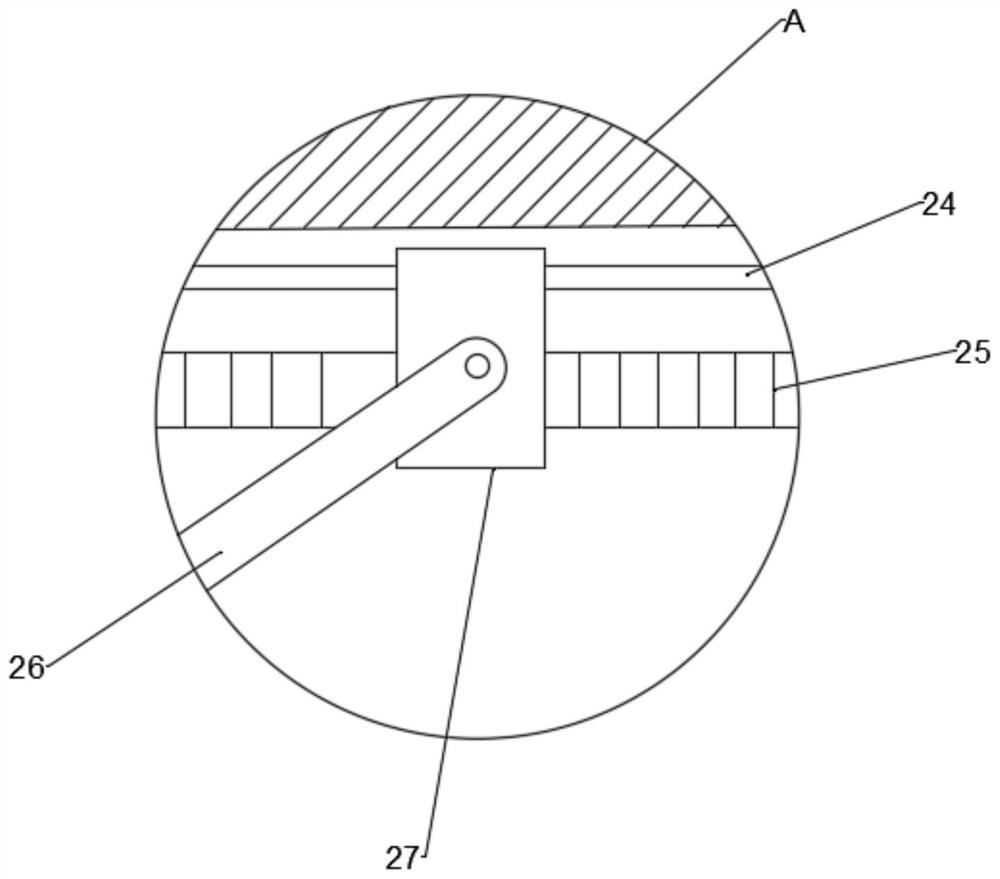

[0024] see Figure 1~4 , in an embodiment of the present invention, a sports equipment casting processing device includes a base 1, the bottom of the base 1 is evenly and symmetrically fixed with a leg 2, and the bottom of the leg 2 is fixed with a rubber pad 3, so The bottom of the rubber pad 3 is provided with a protrusion, which can play the role of shock absorption and anti-skid on the device. The left and right sides of the top of the base 1 are respectively fixedly connected with supporting columns 6, and the tops of the two supporting columns 6 are fixedly connected. There is a top plate 17, the bottom of the top plate 17 is fixedly connected with a moving plate 18 through an electric push rod 23, and the two ends of the moving plate 18 are respectively slidably connected with the support column 6 through a chute, and the middle position of the bottom of the moving plate 18 is A movable rod 21 is hinged, and the bottom of the movable rod 21 is fixedly connected with a f...

Embodiment 2

[0028] see Figure 5 , The difference between this embodiment and Embodiment 1 is that a cooling water tank 13 is fixedly installed at one end of the two support columns 6 respectively, and a water pump 14 is provided at the top of the cooling water tank 13, and the top of the water pump 14 is connected to There is a water pipe 15, and one end of the water pipe 15 is connected with a shower head 16, and the shower head 16 is located above the workbench 12.

[0029]The working principle of the present invention is: when using a kind of sports equipment casting processing device of the present invention, at first the casting that needs processing is placed on the workbench 12, pushes the fixture 36 by cylinder 35 to be close to each other and the casting is fixed, then by controlling electric The push rod 23 moves downward, drives the grinding head 32 to move downward, starts the first motor 20 to drive the grinding head 32 to polish the casting, starts the second motor 22 to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com