Multi-directional edge grinding equipment for mailbox production process

A technology of production process and edging equipment, which is applied in the field of multi-directional edging equipment for letter box production process, can solve the problems of increased labor cost, inconvenient grinding consistency, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

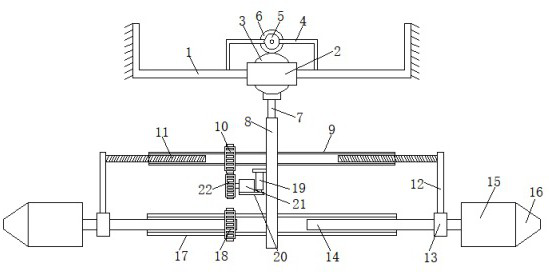

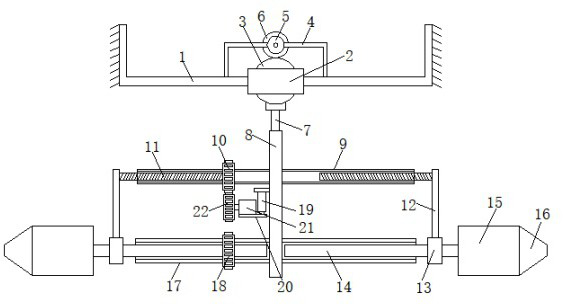

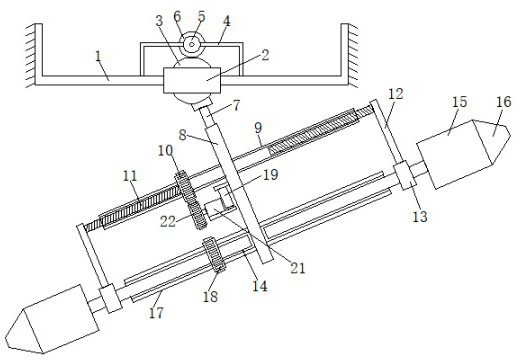

[0025] refer to image 3 with Figure 5 : A kind of multi-directional edging equipment used in the production process of letter boxes, including two mounting plates 1, a steering adjustment mechanism is arranged between the two mounting plates 1, the bottom of the steering adjustment mechanism is connected with a fixed shaft 7 in rotation, and the fixed shaft 7 The bottom end is fixedly connected with a hanging plate 8, and the inner rotation of the hanging plate 8 is connected with a sleeve 17. The outer fixed sleeve of the sleeve 17 is provided with a second gear 18, and the movable sleeves on both sides of the sleeve 17 are provided with a grinding mechanism. The top of 17 is provided with spacing adjusting mechanism.

[0026] In the present invention, the steering adjustment mechanism includes a fixed rod 4 fixedly connected to the top of the mounting plate 1, the top of the fixed rod 4 is fixedly connected with a first drive motor 5, and the output shaft of the first dri...

Embodiment 2

[0029] refer to Figure 1-2 with Figure 4 A kind of multi-directional edging equipment used in the production process of letter boxes, the grinding mechanism includes a transmission rod 14 that is movably sleeved inside the casing 17, and the ends of the two transmission rods 14 that are far away from each other are fixedly connected with the first grinding head 15. A side of the first grinding head 15 that is far away from each other is fixedly connected with a second grinding head 16, and the transmission rod 14 is a cuboid structure. The first gear 10 is sleeved, the threaded sleeves on both sides of the threaded pipe 9 are provided with screw rods 11, and the ends of the two screw rods 11 that are far away from each other are fixedly connected with a connecting plate 12, and the bottom of the connecting plate 12 is fixedly connected with a bearing 13, and the bearing 13 is sleeved on the outside of the transmission rod 14, and a driving mechanism is provided between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com