Casting piece grinding robot

A technology of robots and castings, which is applied in the direction of grinding machines, manufacturing tools, grinding workpiece supports, etc., can solve the problems of poor grinding effect and poor accuracy of arcs or depressions, so as to improve the quality of grinding and improve grinding Accuracy, the effect of improving the accuracy of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

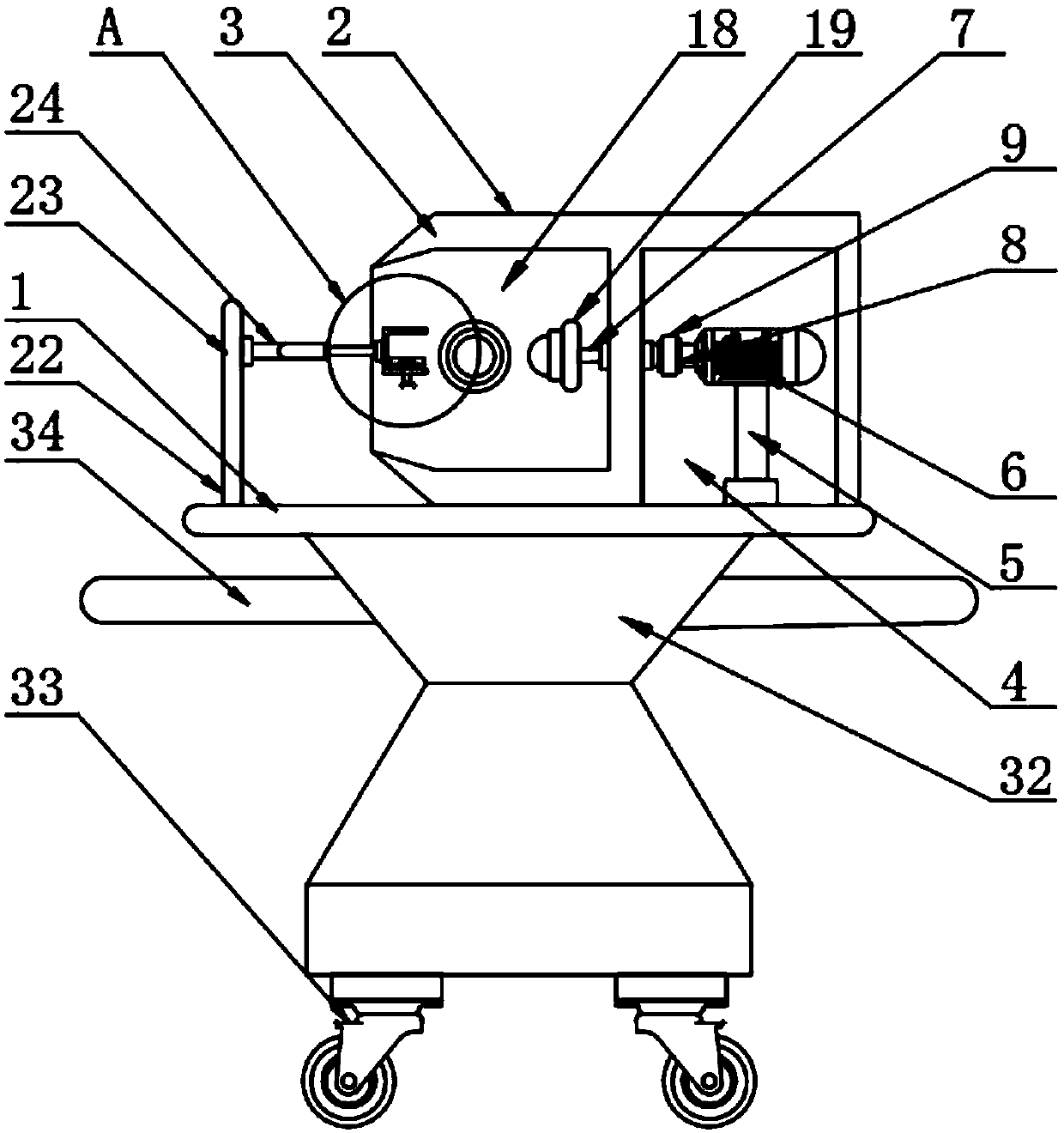

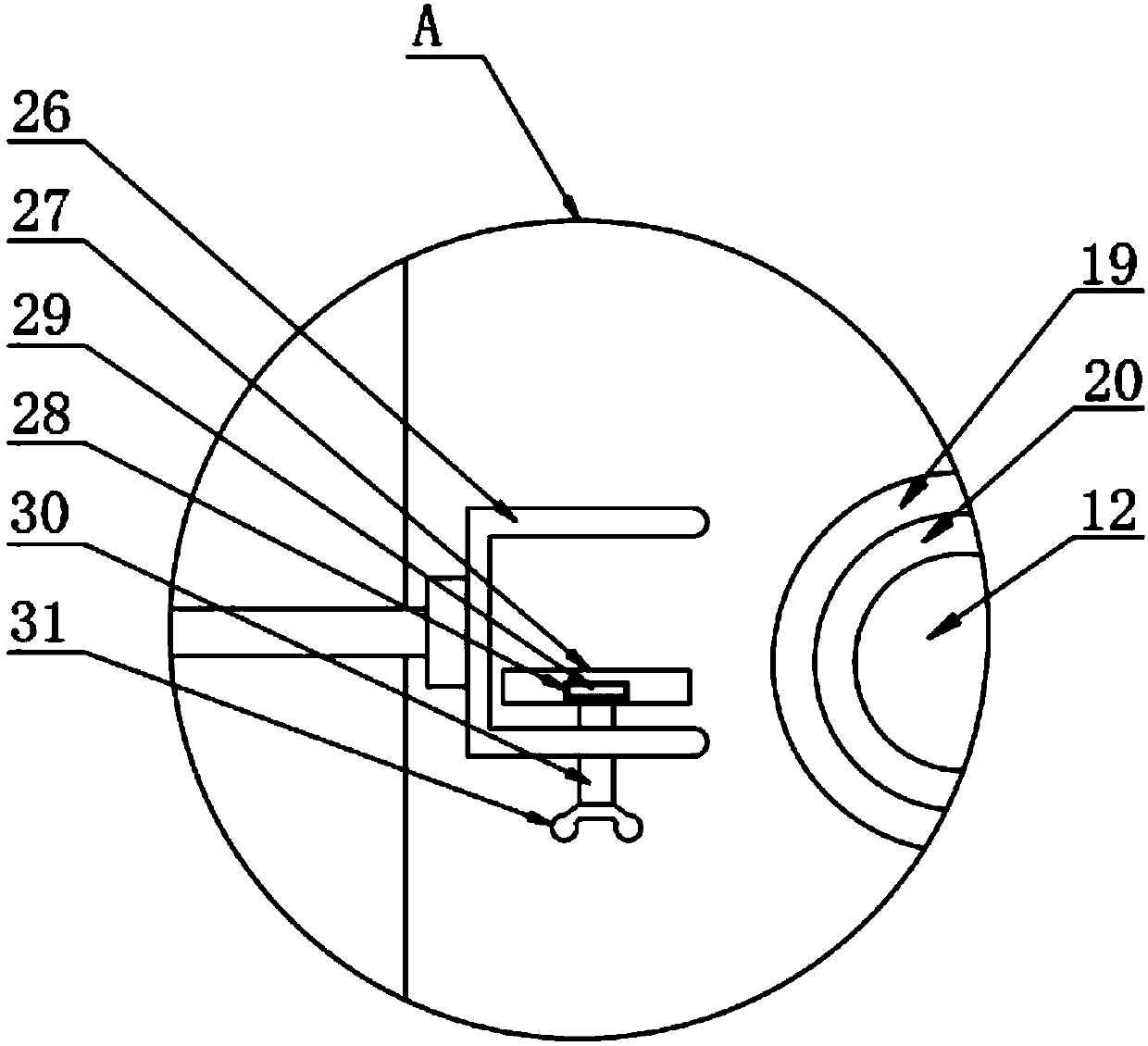

[0026] The present invention provides such Figure 1-5 The casting grinding robot shown includes a working platform 1, a grinding device 2 is provided on the top of the working platform 1, and the grinding device 2 includes a grinding box 3, and a first power chamber 4 is arranged inside the grinding box 3 , the inside of the first power chamber 4 is provided with a support rod 5, the support rod 5 is fixedly connected with the inner wall of the first power chamber 4, the top of the support rod 5 is provided with a servo motor 6, and one side of the servo motor 6 is provided There is a first rotating shaft 7, the output shaft of the servo motor 6 is fixedly connected with the first rotating shaft 7, a first gear 8 is provided on the outside of the first rotating shaft 7, and a tooth chain belt 9 is provided on the outside of the first gear 8, so The first gear 8 meshes with the toothed chain belt 9, the toothed chain belt 9 is provided with a second gear 10 inside, the second ...

Embodiment 2

[0029] Further, in the above-mentioned embodiment 1, a fixing device 22 is provided on one side of the grinding box 3, and the fixing device 22 includes a side plate 23, and the side plate 23 is fixedly connected with the working platform 1;

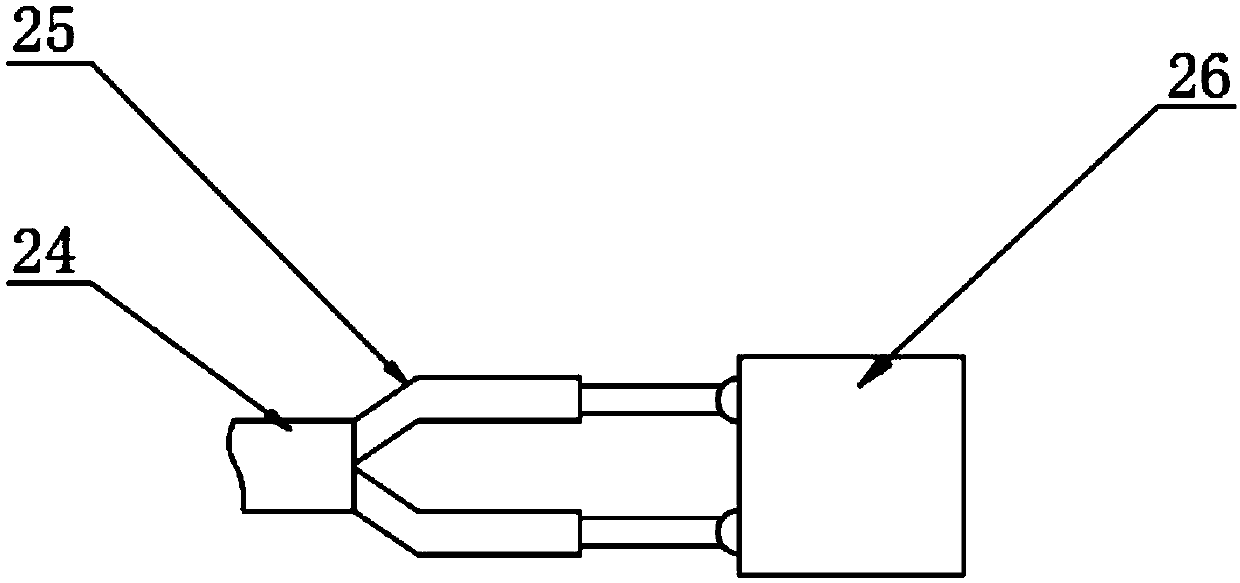

[0030] One side of the fixed plate 14 is provided with a connecting rod 24, and one side of the connecting rod 24 is provided with an electric telescopic rod 25;

[0031]One side of the electric telescopic rod 25 is provided with a fixed shell 26, and the output shaft of the electric telescopic rod 25 is hinged with the fixed shell 26. By setting the fixing device 22, the material is placed inside the fixed shell 26, and the button plate 31 is rotated. 31 Drive the rotary block 29 to rotate inside the limiting groove 28 through the screw rod 30, and then the brick pushes the pressing plate 27 to fix the material, and at the same time opens the electric telescopic rod 25, and the two electric telescopic rods 25 can push the fixed shell 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com