Adjustable glass edging device

A glass edging and adjusting device technology, which is applied to machine tools, grinders, and grinding feed motions suitable for grinding workpiece edges, can solve the problem that glass edging machines cannot change the grinding angle at will, and increase the number of users. Economic burden and other issues, to achieve the effect of reducing the number and time of installation, reliable installation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

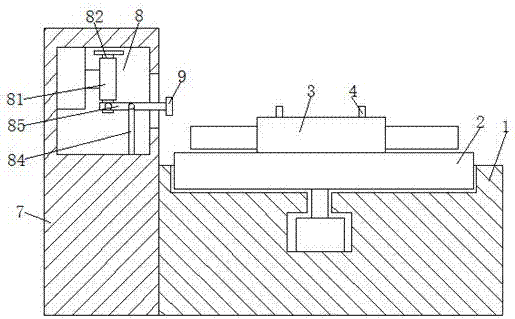

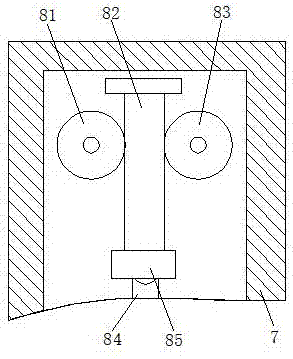

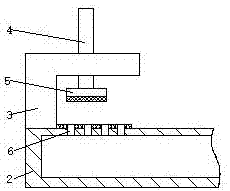

[0018] refer to Figure 1-3 , an adjustable glass edging device, including a workbench 1, one side of the workbench 1 is provided with a mounting plate 2, and the side of the mounting plate 2 away from the workbench 1 is provided with two sets of baffles 3, the inside of the workbench 1 A driving motor is provided, and a rotating rod is provided in the center of the side of the mounting plate 2 away from the baffle 3. The output end of the driving motor is connected with the rotating rod through a shaft connector. Both groups of baffles 3 are connected with two sets of threads through threaded holes. Pressure rod 4, the end of the threaded pressure rod 4 close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com