Double-station horizontal machining center complete machine structure and control system thereof

A technology of machining center and complete machine structure, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of convenience of double-station processing control, unsatisfactory control effect and low convenience of control, etc., to achieve Control convenience and good control effect, good use effect and high unloading convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

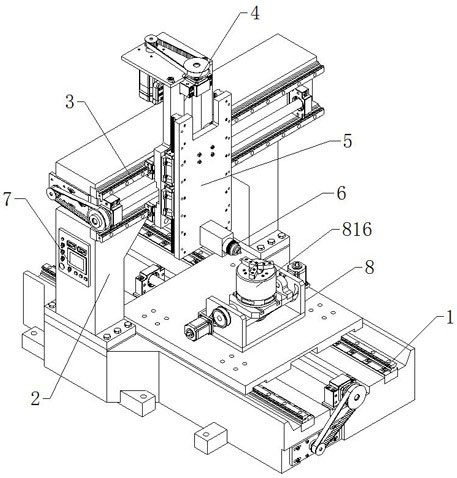

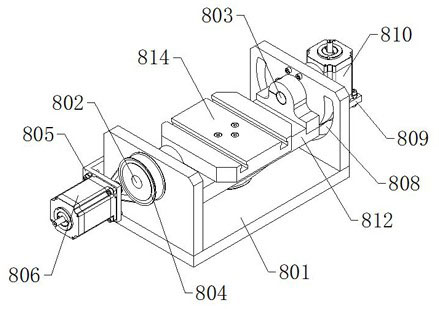

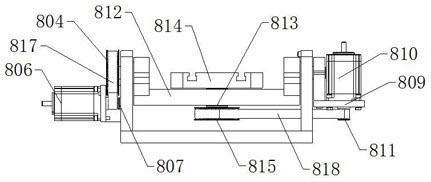

[0024] Example: see Figure 1-3 The complete machine structure of a double-station horizontal machining center shown includes a Z-axis displacement module 1, a loading frame 2 is arranged on the rear side of the end of the Z-axis displacement module 1, and a front upper side of the loading frame 2 is provided with a loading frame 2. The X-axis displacement module 3, the Y-axis displacement module 4 is installed on the sliding seat of the X-axis displacement module 3, the loading plate 5 is arranged on the sliding seat of the Y-axis displacement module 4, and the front lower side of the loading plate 5 is arranged There is a processing head 6, a PLC controller 7 is arranged on the left side of the loading frame 2, a processing positioning assembly 8 is arranged on the sliding seat of the Z-axis displacement module 1, and the processing positioning assembly 8 includes a loading seat 801. A first installation shaft 802 is rotatably installed in the middle of the left side, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com