Transformer substation monitoring system debugging method based on digital twinning

A substation monitoring and debugging method technology, applied in the direction of electrical components, circuit devices, etc., can solve the problems of secondary professional safety, quality and efficiency improvement constraints, automated debugging personnel running broken legs, and the impact of team carrying capacity, etc., to achieve saving The effects of on-site service expenses, shortened commissioning period, and reduced equipment outage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

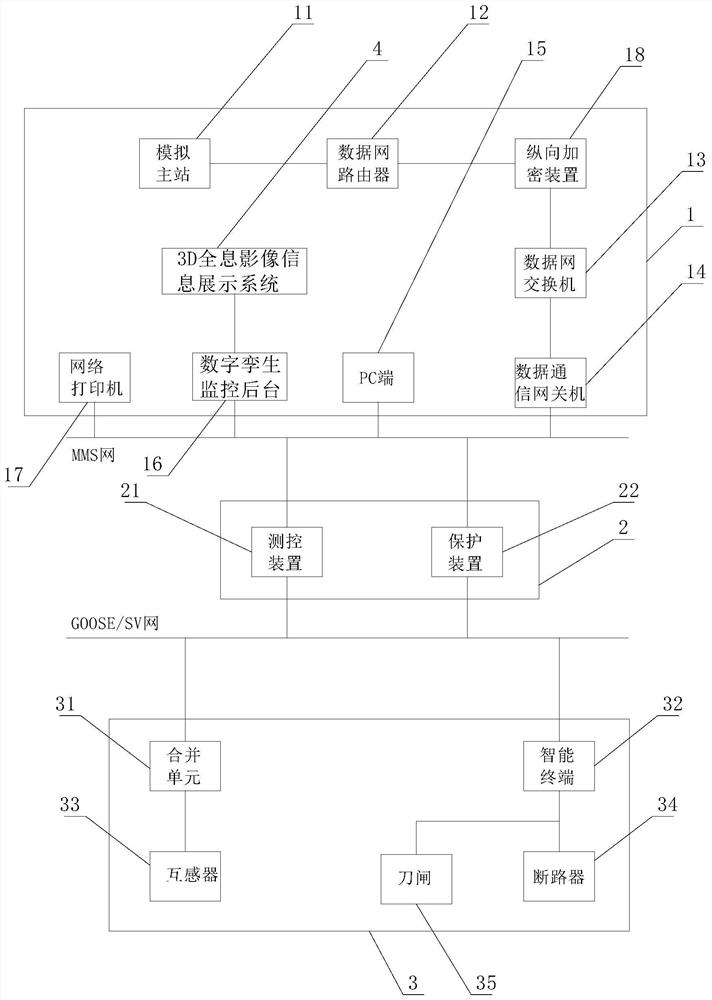

[0028] A method for debugging a substation monitoring system based on a digital twin, including a substation monitoring system, such as figure 1 As shown, the substation monitoring system includes a station control layer 1, an interval layer 2 and a process layer 3, the station control layer is connected with the process layer through the interval layer, and the station control layer includes an analog master station 11, a data network router 12 , data network switch 13, data communication gateway machine 14, PC terminal 15 and digital twin monitoring background 16, the simulation master station is connected with the data network router, the data network router is connected with the data network switch, the data network switch, Both the PC terminal and the digital twin monitoring background are connected to the data communication gateway machine. The bay layer includes a measurement and control device 21 and a protection device 22, and the process layer includes a merging unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com