Split type outer water cutting structure and vehicle

An external water cutting and split-type technology, which is applied to vehicle parts, engine seals, sealing devices, etc., can solve the problems of low qualified rate of finished products, unstable extrusion process, and poor product stability, so as to speed up the manufacturing process and reduce The effect of repeatedly adjusting the problem and reducing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

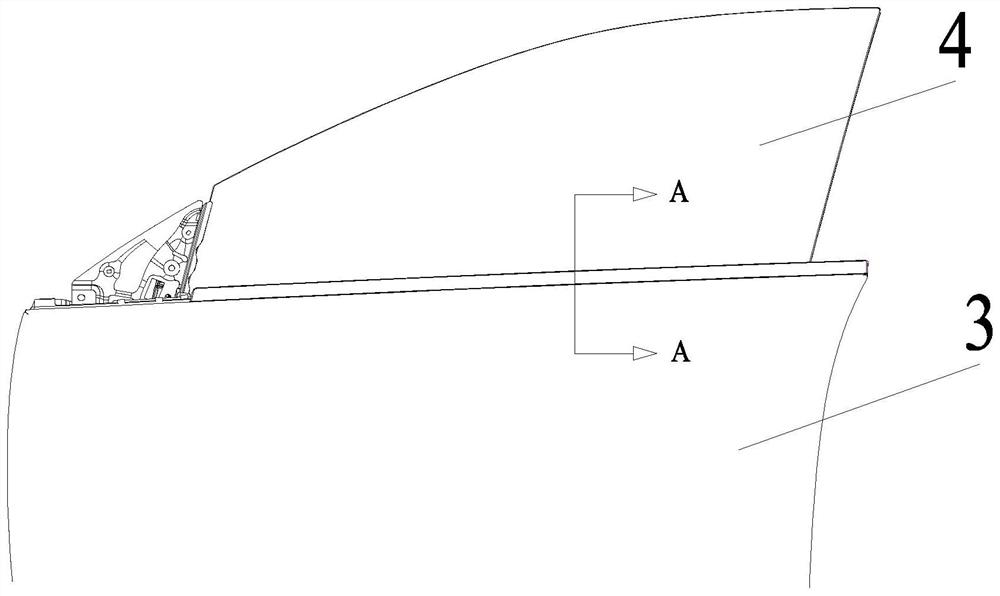

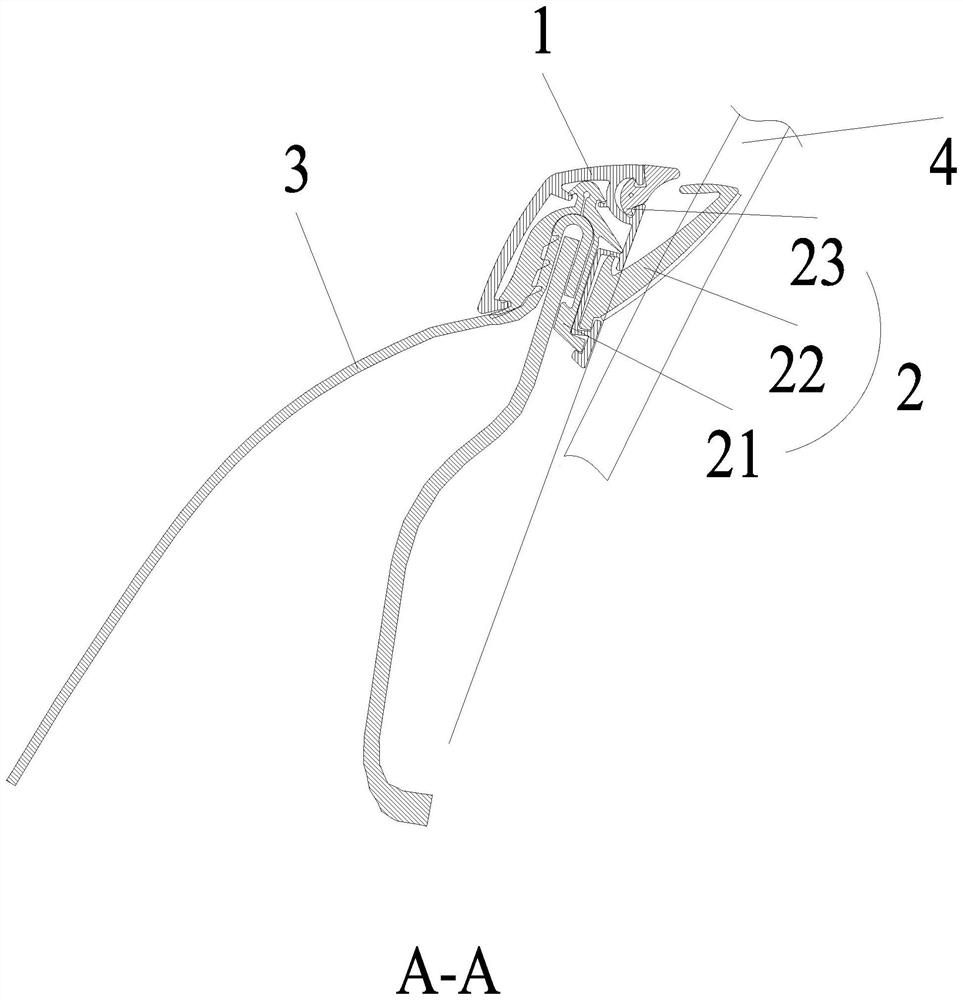

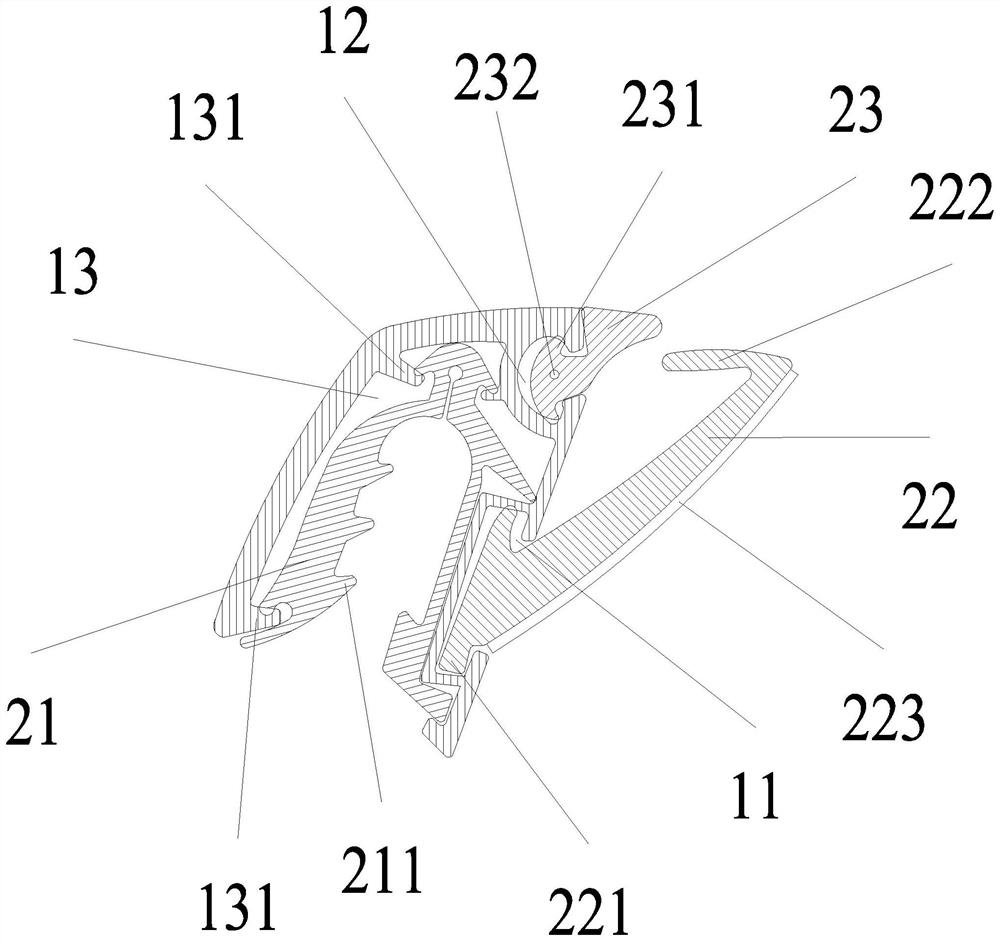

[0021] like figure 1 Only image 3 As shown, a split-type outer water-cutting structure includes a metal frame 1 and a water-cutting body 2. The water-cutting body 2 includes a sealing lip 22 and an upper lip 23 connected separately to the metal frame 1. The metal frame 1 is connected to the door The outer panel 3 is fixedly connected, and the sealing lip 22 abuts against the door glass 4 . The traditional outer water-cutting structure is compounded and co-extruded by the metal skeleton 1 and the water-cutting body 2. Among them, the metal skeleton 1 is mostly aluminum alloy, and the water-cutting body is made of EPDM material. In addition, the water-cutting body 2 is often set to improve the stability of the water-cutting body. Therefore, the traditional external water-cut structure is actually made of three kinds of materials by compound co-extrusion; but the shrinkage rate of different materials is inconsistent, and the product stability is poor; it also puts forward high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com