An intelligent material conveying device and operation method

A technology for conveying devices and materials, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of slow efficiency, sideways feeding, and material damage caused by humans, and achieve intelligent material transportation and enhanced blanking The effect of high quality and convenient stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

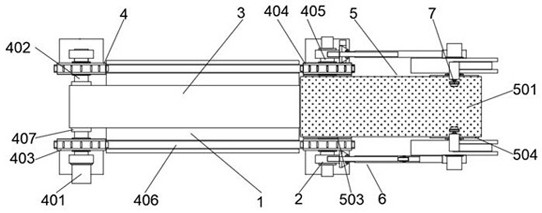

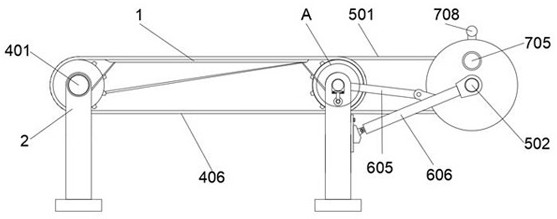

[0039] like figure 1 - Figure 8 As shown, an intelligent material conveying device includes a conveying platform 1, a support column 2, a first conveying belt 3, a conveying drive assembly 4, an auxiliary conveying structure 5, two fixed-point deflection structures 6 and two anti-rollover structures 7 , there are four supporting columns 2, the supporting columns 2 are symmetrically arranged at the four corners of the conveying platform 1, the first conveyor belt 3 is sleeved on the outer side of the conveying drive assembly 4 and the conveying platform 1 and abuts with it, and the auxiliary conveying structure 5 is arranged on one side of the conveying platform 1, the fixed-point deflection structure 6 is symmetrically arranged on both sides of the auxiliary conveying structure 5, the anti-rollover structure 7 is installed on the opposite surface of the fixed-point deflection structure 6, and the two fixed-point deflection structures 6 work synchronously. Each anti-rollover ...

Embodiment 2

[0059] Based on the operation method of an intelligent material conveying device in Embodiment 1, the specific operation steps are as follows:

[0060] After the material falls on the first conveyor belt 3, start the conveying drive assembly 4 to work and make the first conveyor belt rotate. After the first conveyor belt rotates, it drives the material to move in the direction of the auxiliary conveying structure 5. At the same time, the conveying drive assembly 4 works and transmits kinetic energy to the conveyor. The second conveyor belt 501 of the auxiliary conveying structure 5 makes the second conveyor belt 501 rotate synchronously. When the material reaches the second conveyor belt 501 of the auxiliary conveying structure 5, the second conveyor belt 501 drives the material away from the first conveyor belt 3 and reach the end of the second conveyor belt 501;

[0061] When the material reaches the end of the second conveyor belt 501, and at the same time, when it is detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com