Line-driven flexible robot

A robot and line-driven technology, applied in the field of flexible robots, can solve the problems of difficulty in reducing manufacturing costs, large overall inertia, length and flexibility limitations of mechanical arms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the following embodiments describe a wire-driven flexible robot of the present invention in detail with reference to the accompanying drawings. The description is used to help the understanding of the present invention, but does not constitute a limitation of the present invention.

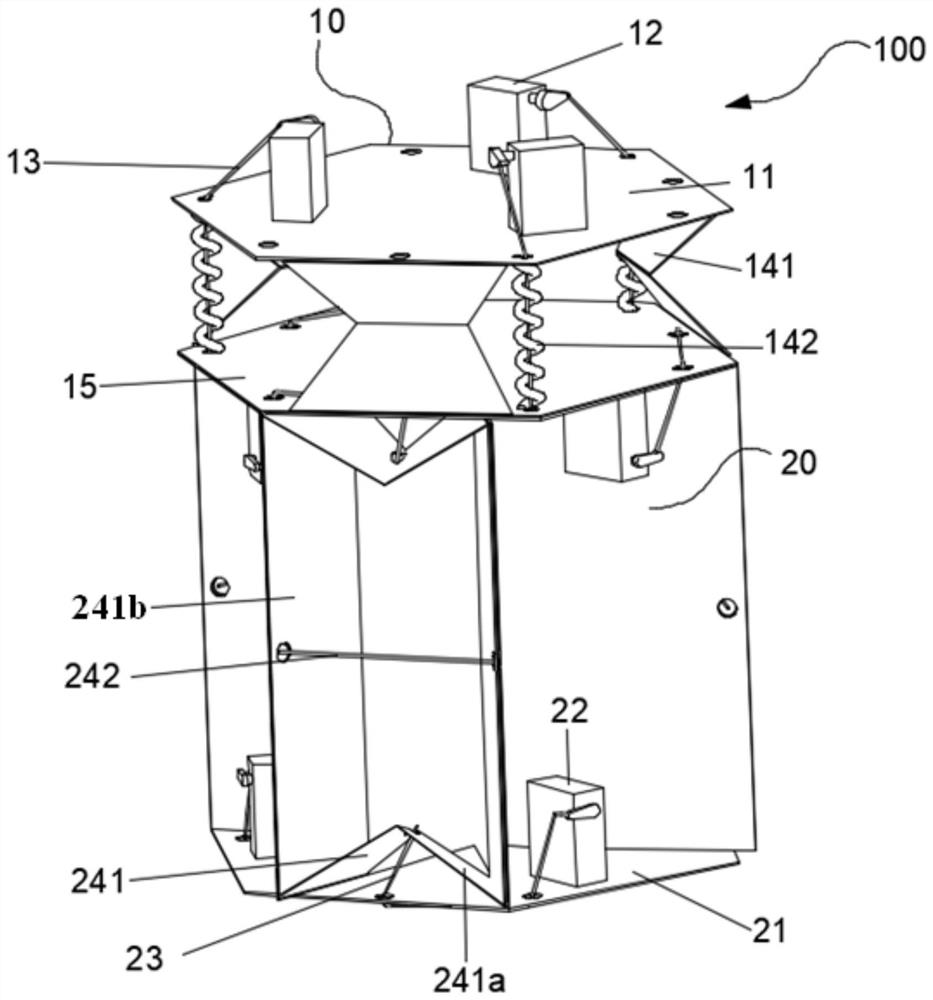

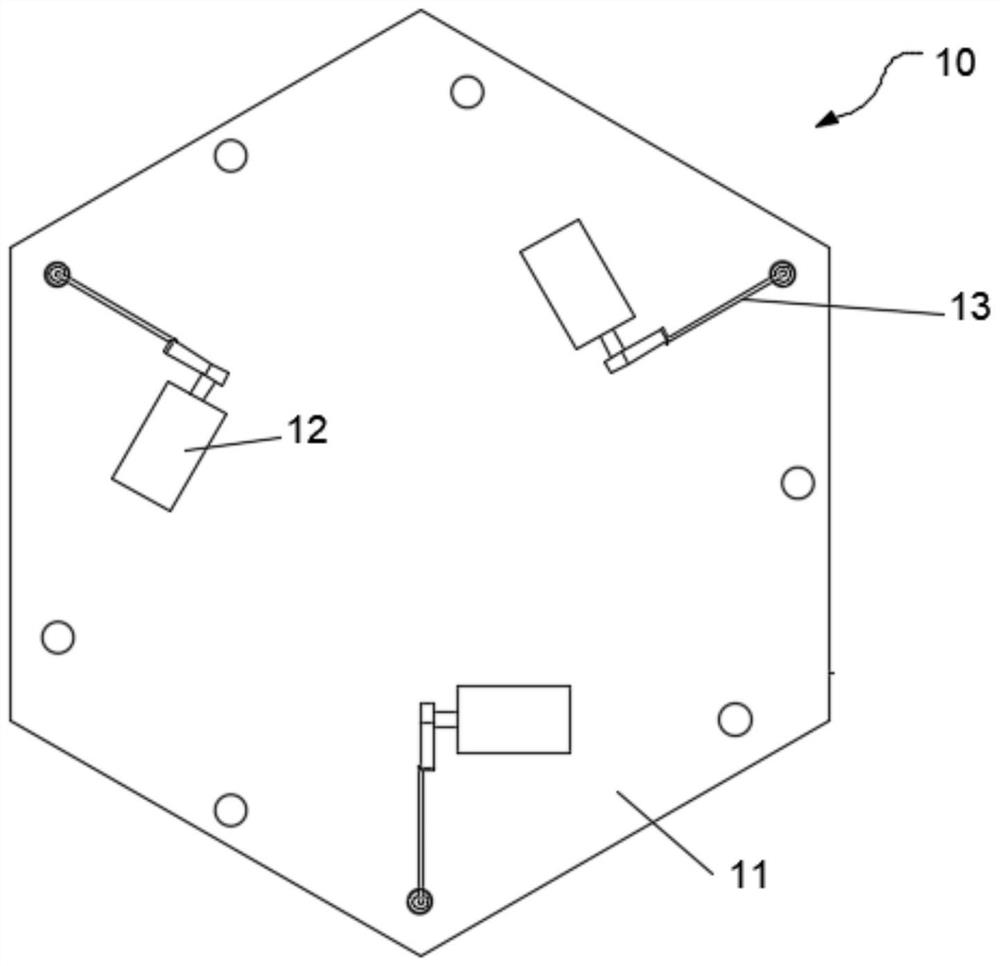

[0027] like figure 1 As shown, the wire-driven flexible robot 100 in this embodiment is used to carry an execution element such as a manipulator through an execution platform, and perform three-dimensional execution operations in a narrow space.

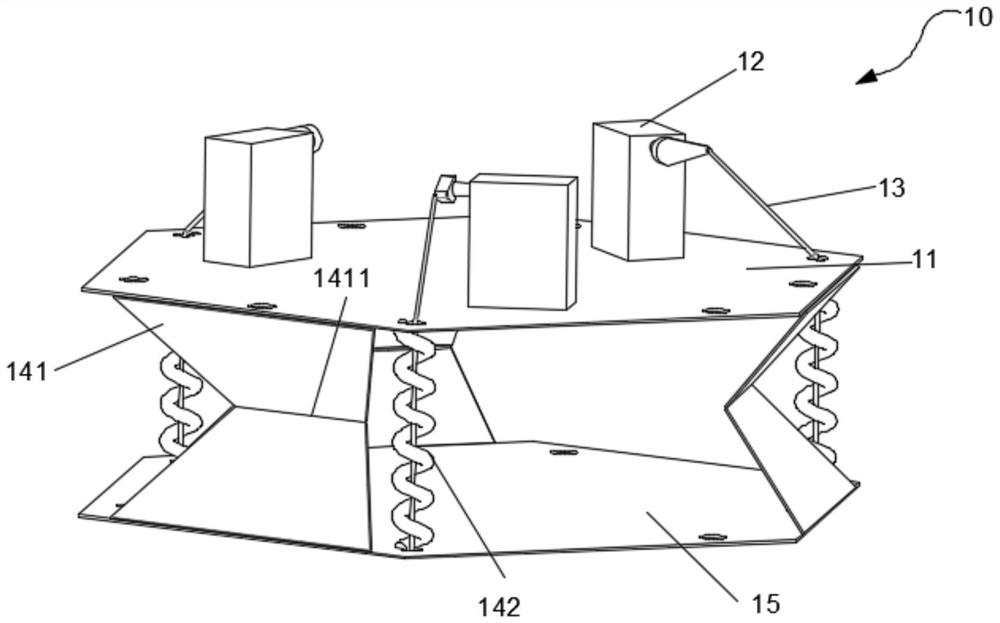

[0028] The wire-driven flexible robot 100 includes a twisting deformation unit 20 and a bending deformation unit 10 which are connected in sequence. Specifically, when the wire-driven flexible robot 100 is not in operation, the bus line of the wire-driven flexible robot 100 is arranged in a straight line.

[0029] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com