Wire drawing equipment for curved television metal machine shell

A curved TV and casing technology, applied to metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., to achieve the effects of increased friction, low cost, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

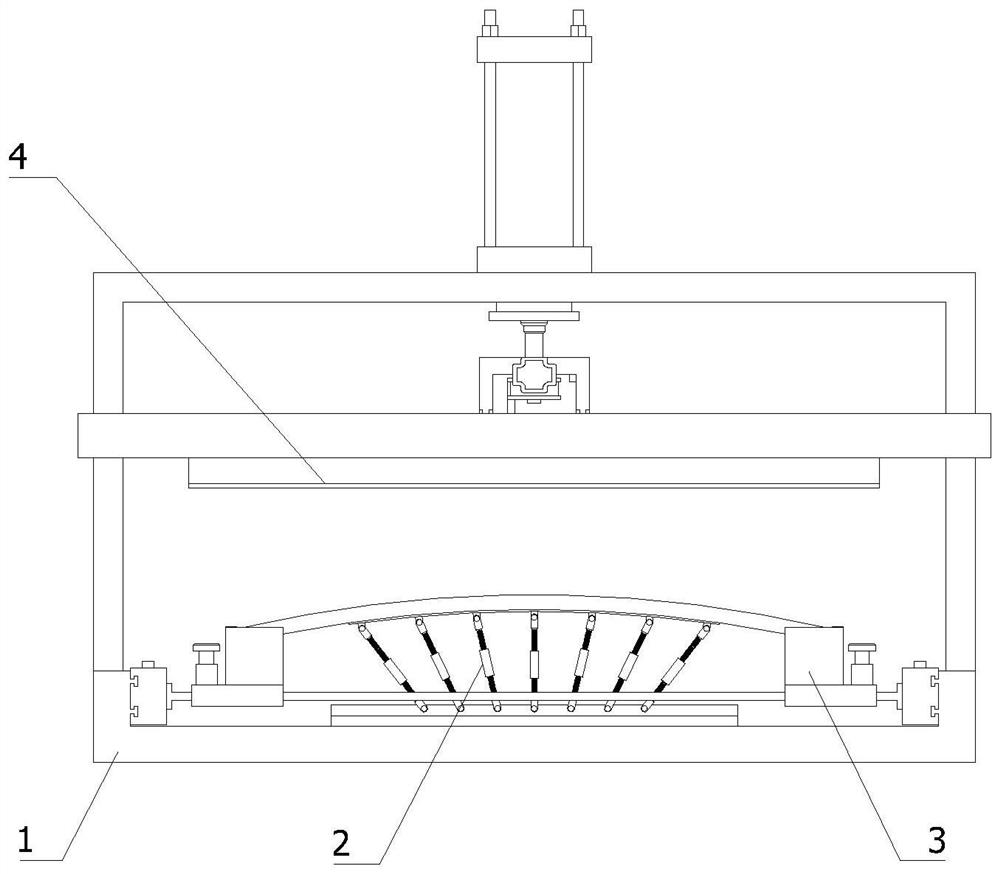

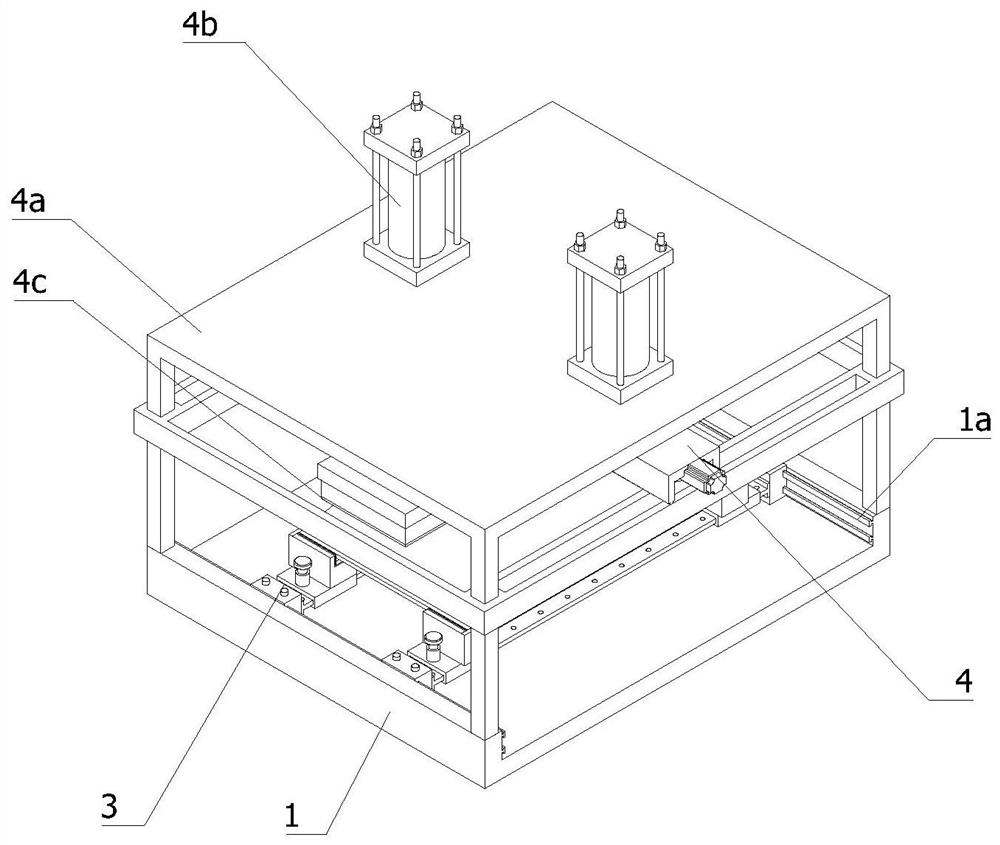

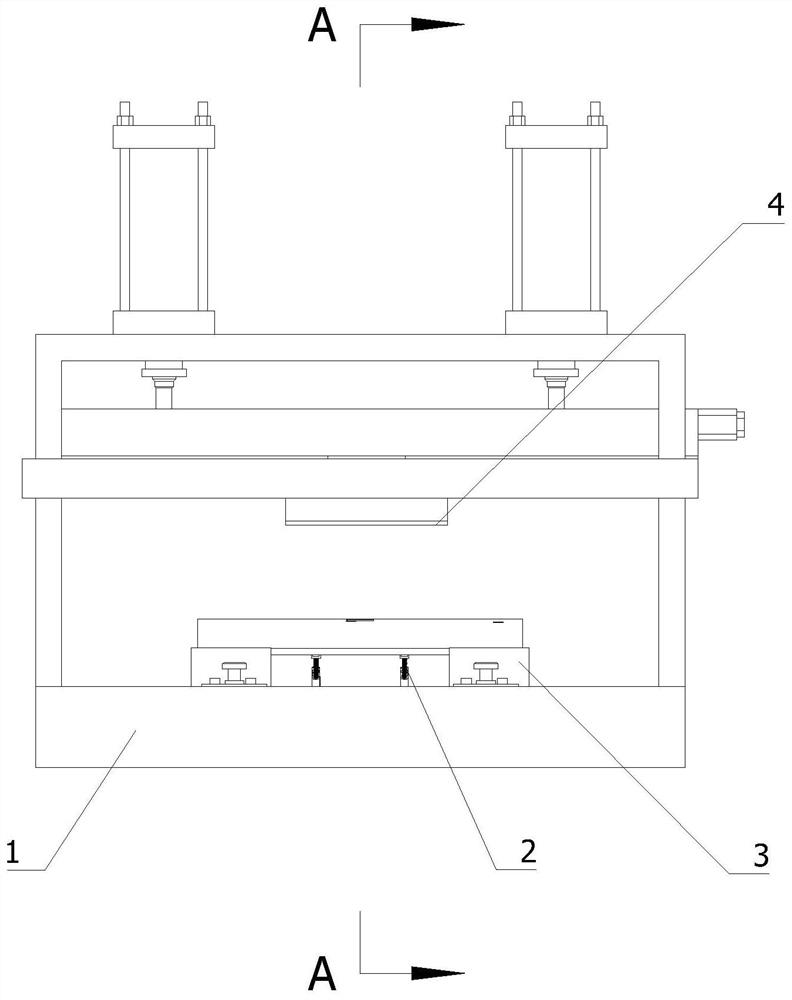

[0045] In order to solve the technical problem of how to fix and support curved metal shells with different sizes and different curvatures to ensure that they will not be deformed by force and change the curvature during the wire drawing process, such as Figure 1 to Figure 3 As shown, the following technical solutions are provided:

[0046] A wire drawing equipment for a curved TV metal casing, comprising a base 1, a curved flexible support mechanism 2 that can adjust the curvature of the working end is installed in the center of the base 1, and the curved flexible support mechanism 2 is used to place the metal casing to be processed For support, the two sides of the curved surface flexible support mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com