An automatic painting system for enameled wire

A technology for enameled wires and wires, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problems of difficulty in achieving consistent paint film thickness, restricting wire insulation performance, and low applicability, so as to avoid uneven distribution of paint volume , improve the quality of painting, improve the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

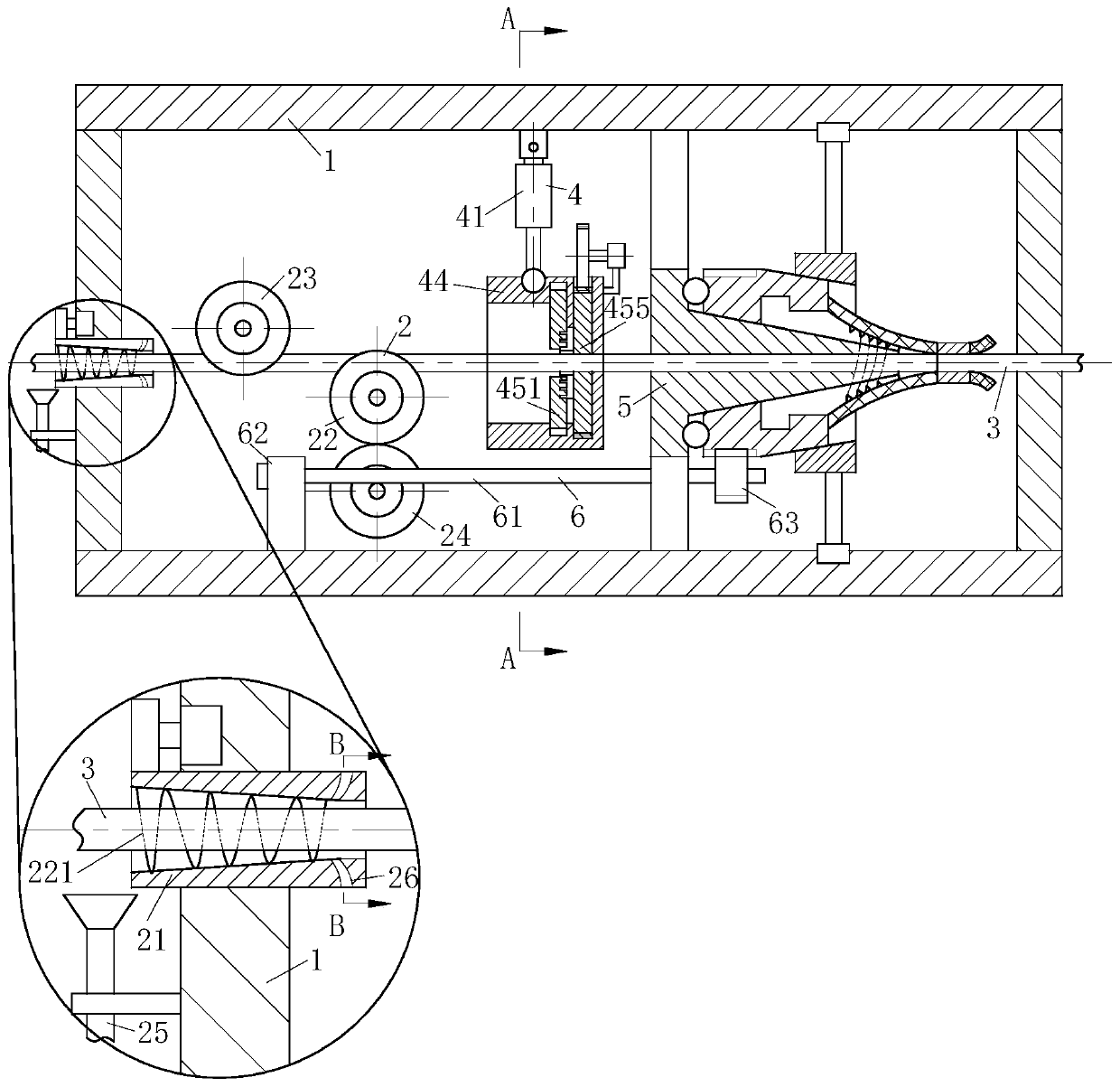

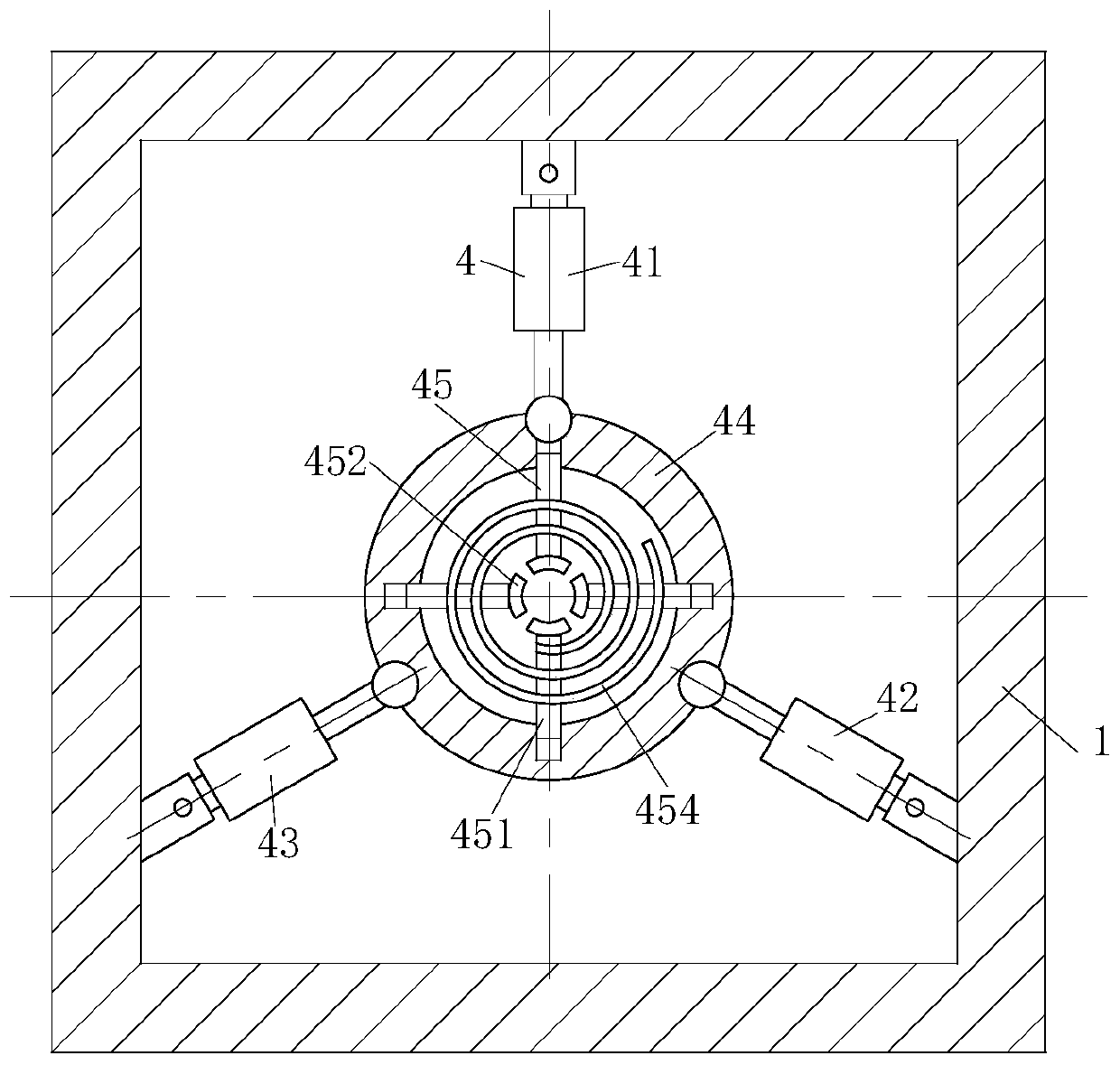

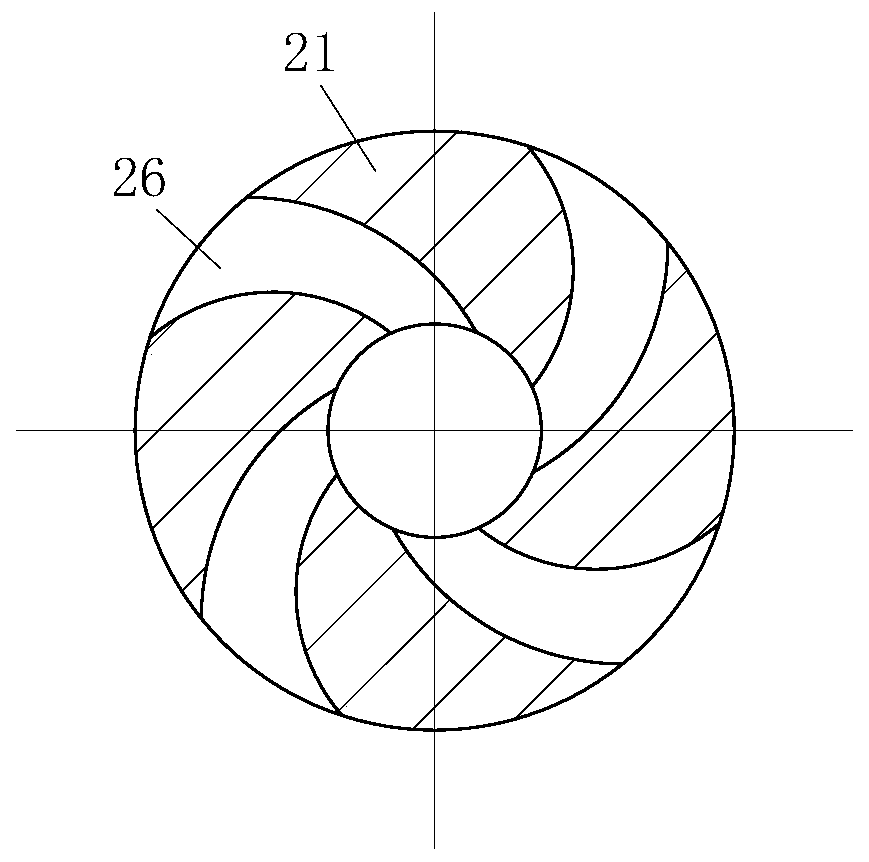

[0028] As an embodiment of the present invention, the adjustment unit 45 includes a sliding rod 451, a sponge block 452, a spiral groove 453, a spiral disc 454 and a mounting ring 455; the number of the sliding rods 451 is set to four; the sliding rod 451 Slidingly installed inside the paint ring 44, and arranged along the ray direction of the paint ring 44; the sliding rod 451 is provided with an arc-shaped sponge block 452 near the center of the paint ring 44; The block 452 is used for painting the wire 3; the end of the sliding rod 451 connected to the sponge block 452 is provided with a spiral groove 453; the spiral groove 453 is internally connected to the spiral disk 454; the spiral disk 454 is fixedly installed on one side of the mounting ring 455 The installation ring 455 is concentrically rotated and installed in the painting ring 44; the rotation of the spiral disk 454 is used to adjust the spacing of the sponge blocks 452; in the production process, it is often neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com