Cutting device for logo label manufacturing

A sign, cutting technology, applied in metal processing and other directions, can solve the problems of deviation in cutting angle, affect the use effect, complex adjustment method, etc., and achieve the effect of simple adjustment, simple operation method and good cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

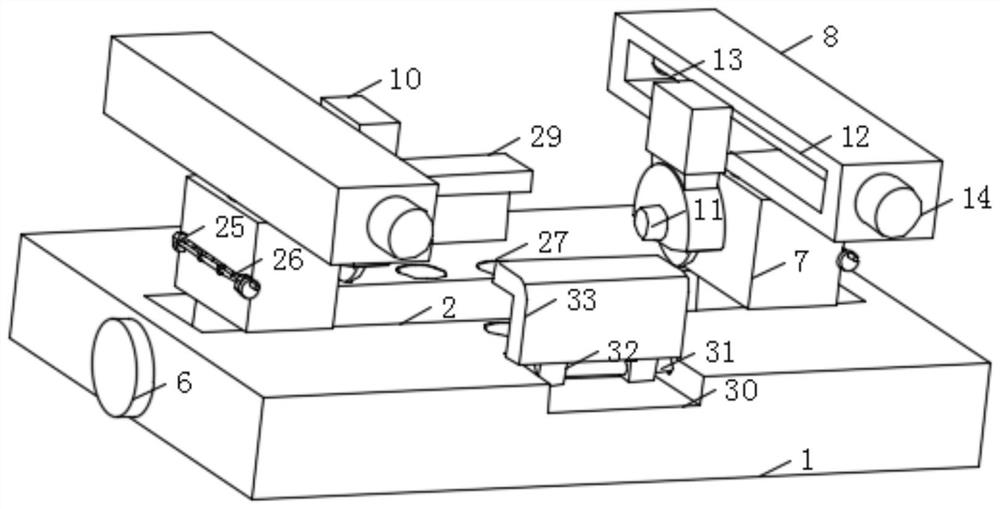

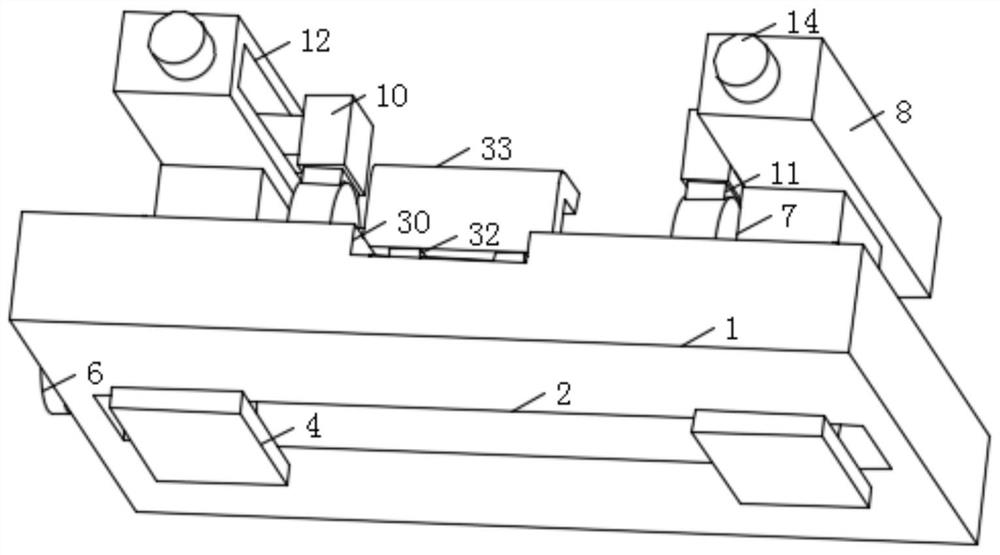

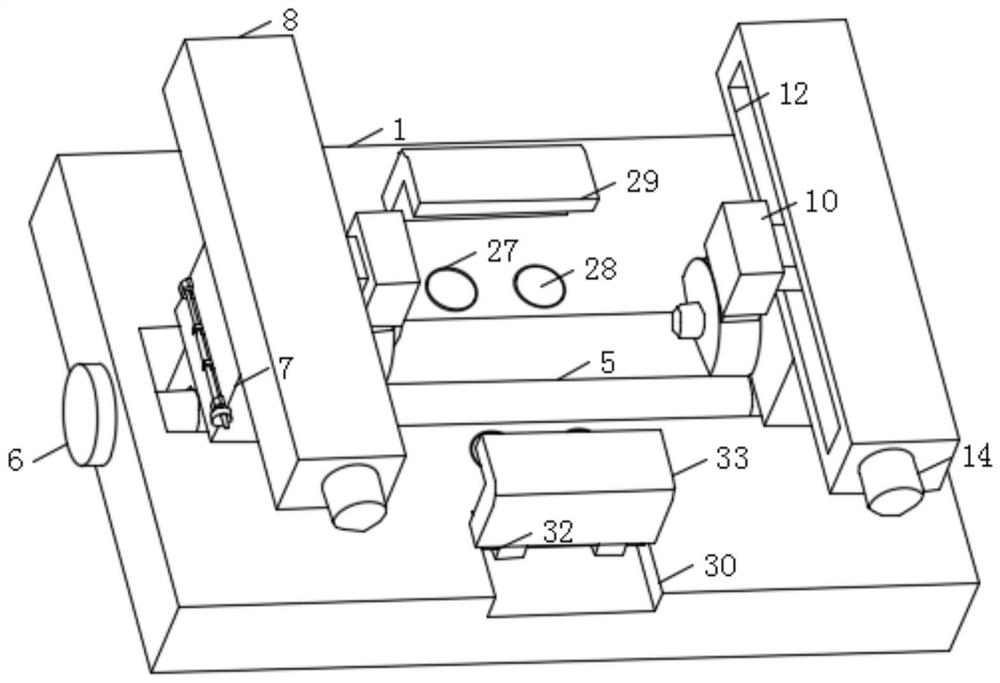

[0024] refer to Figure 1-3 , a cutting device for making a signage, comprising an operating table 1, and two fixing blocks 7 are installed on the operating table 1 through a spacing adjustment mechanism.

[0025] It is worth noting the above:

[0026] 1. The spacing adjustment mechanism is composed of a chute 2, a bidirectional screw rod 5, a turntable 6, two sliders 3 and two fixed plates 4.

[0027] 2. The chute 2 is set on the operating table 1, the two sliding blocks 3 are fixedly installed on the lower ends of the two fixing blocks 7 respectively, and the two sliding blocks 3 are slidably connected in the chute 2, and the two fixing plates 4 are respectively fixed Installed on one end of the two sliders 3 outside the console 1, the two-way screw 5 is rotatably connected in the chute 2, and the two-way screw 5 and the two sliders 3 are both threadedly connected, and the turntable 6 is fixedly installed in the two-way. The screw 5 is located on one end outside the consol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com